As plastic waste continues to challenge manufacturers worldwide, finding efficient and cost-effective recycling solutions has become critical. At Energycle, we’ve engineered the Storcător de folie de plastic to address one of the most persistent problems in plastic recycling: effectively processing wet, contaminated plastic films while maximizing energy efficiency and throughput.

Why Plastic Film Recycling Needs Specialized Equipment

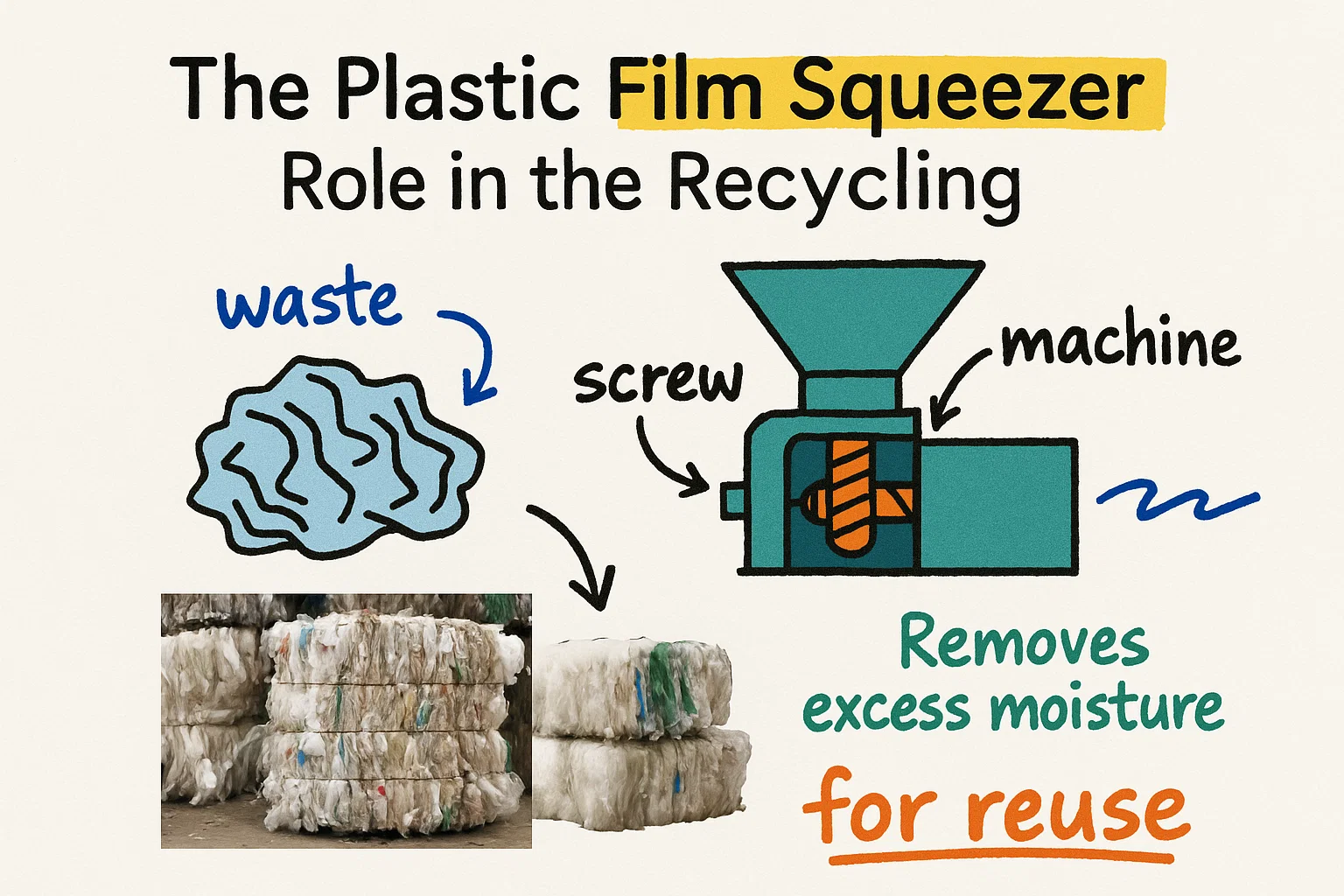

Plastic films—from agricultural mulch to industrial stretch wrap—represent a significant recycling challenge. Their high surface area retains moisture and contaminants, making traditional drying methods energy-intensive and often ineffective. This is where Energycle’s Plastic Film Squeezer delivers measurable performance advantages for recycling operations of all scales.

Advanced Dewatering Technology That Reduces Operating Costs

Our Plastic Film Squeezer combines mechanical dewatering with integrated heating to achieve moisture reduction rates that dramatically lower your downstream drying costs. The screw press mechanism applies consistent, controlled pressure to squeeze out up to 40-50% of water content from washed films—significantly more than conventional dewatering equipment.

What sets Energycle apart:

- High-torque screw design engineered specifically for film materials (LDPE, LLDPE, HDPE, and PP woven bags)

- Integrated heating zones that prepare material for immediate densification

- Continuous operation capability supporting throughputs from 300 to 1,200 kg/h

- SKD-11 hardened steel components in wear zones for extended service life

- Reduced energy consumption by 30-40% compared to thermal drying alone

The Complete Densification Process

Energycle’s system doesn’t stop at dewatering. The squeezed films pass directly into our densification chamber, where controlled heat and mechanical compression transform loose, bulky films into dense, uniform granules. This two-stage approach delivers:

- Consistent bulk density (300-450 kg/m³) that optimizes storage and transport

- Immediate readiness for pelletizing or direct extrusion

- Minimal material degradation through precise temperature control

- Contamination reduction as residual oils and fine particles are expelled during compression

Proven Environmental and Economic Benefits

Measurable Sustainability Impact

When you choose Energycle’s Plastic Film Squeezer, you’re investing in technology that delivers quantifiable environmental results:

- Reduced landfill diversion: Process materials that would otherwise be too contaminated or wet for conventional recycling

- Lower carbon footprint: Energy savings translate directly to reduced CO₂ emissions—up to 2 tons of CO₂ per ton of film processed compared to virgin plastic production

- Water conservation: Efficient moisture removal means less water consumption in your overall washing line

- Extended equipment life: Less moisture downstream means reduced corrosion and maintenance in pelletizing equipment

Real-World ROI for Your Operation

Recycling plant operators partnering with Energycle consistently report:

- 20-35% increase in processing capacity by eliminating drying bottlenecks

- Payback periods of 18-24 months through energy savings and increased throughput

- Improved pellet quality from consistently dried feedstock

- Reduced downtime thanks to our robust, low-maintenance design

Why Leading Recyclers Choose Energycle

Technical Excellence Backed by Industry Experience

With over 15 years specializing in plastic recycling equipment, Energycle brings deep engineering expertise to every installation. Our Plastic Film Squeezers are designed by engineers who understand the real-world challenges of contaminated materials, variable feedstock quality, and demanding production schedules.

Energycle advantages:

- Customizable configurations tailored to your specific materials and throughput requirements

- 304 stainless steel construction in all material-contact areas for corrosion resistance

- PLC-based automation with real-time monitoring of temperature, torque, and throughput

- Global technical support with English-speaking engineers available for commissioning and troubleshooting

- Comprehensive warranty and readily available spare parts

Seamless Integration with Your Recycling Line

Our Plastic Film Squeezers integrate effortlessly into both new and existing recycling lines. Whether you’re processing post-consumer LDPE stretch film or contaminated agricultural plastics, Energycle’s engineering team will configure the equipment to match your upstream washing equipment and downstream pelletizing requirements.

Applications Across Multiple Material Streams

Energycle’s Plastic Film Squeezer excels with diverse plastic film types:

- LDPE/LLDPE stretch film (post-consumer and industrial)

- HDPE film (agricultural and packaging)

- Pungi țesute din PP (cement, feed, and fertilizer bags)

- Mixed film bales with moderate contamination

- Printed and laminated films (after washing)

For specialized applications—such as films with oil contamination or unusually thick gauge materials—our engineering team provides detailed feasibility analysis and test processing to ensure optimal results.

Technical Specifications That Matter

When evaluating plastic film dewatering equipment, focus on specifications that directly impact your operation:

| Caracteristică | Energycle Advantage |

|---|---|

| Reducerea umidității | 40-50% water content removal |

| Throughput range | 300-1,200 kg/h (multiple models) |

| Power efficiency | 0.03-0.05 kWh per kg processed |

| Output bulk density | 300-450 kg/m³ |

| Temperature control | PID-regulated heating zones (80-180°C) |

| Material compatibility | PE, PP films 20-200 microns |

Your Next Step Toward More Efficient Recycling

At Energycle, we understand that every recycling operation faces unique challenges. That’s why we offer complimentary processing trials with sample materials from your facility. Send us your washed film samples, and we’ll demonstrate exactly how our Plastic Film Squeezer will perform with your specific materials.

Ready to reduce costs and increase throughput? Contact our technical team today for a detailed ROI analysis customized to your operation.

Întrebări frecvente

How does Energycle’s Plastic Film Squeezer reduce energy costs?

Our system removes 40-50% of moisture mechanically before materials reach thermal drying stages. Since evaporating water requires approximately 2,260 kJ/kg, mechanical dewatering delivers substantial energy savings—typically reducing thermal drying energy by 30-40%. Over a year of operation, this translates to significant cost reductions in electricity or natural gas consumption.

What maintenance does the Plastic Film Squeezer require?

Energycle designs for minimal maintenance. Routine care includes daily inspection of the screw assembly (5 minutes), weekly lubrication of drive components (10 minutes), and quarterly replacement of heating element seals. Our SKD-11 hardened steel screw typically operates 8,000-12,000 hours before requiring refurbishment—far exceeding industry standards.

Can the equipment handle contaminated or mixed-color films?

Yes. The Plastic Film Squeezer processes washed films with typical post-wash contamination levels (up to 3-5% residual dirt, labels, or other polymers). For heavily contaminated materials or mixed-color streams, we recommend pairing the squeezer with our upstream washing equipment for optimal results. Contact our team to discuss your specific material challenges.

How does this technology support circular economy goals?

Energycle’s Plastic Film Squeezer makes previously unrecyclable materials economically viable to process. By reducing energy barriers and handling difficult-to-dry films, the equipment expands the range of plastics your facility can divert from landfills. The densified output integrates directly into pelletizing lines, creating high-quality recycled pellets suitable for manufacturing new products—closing the loop from waste to resource.

What makes Energycle different from other squeezer manufacturers?

Three factors distinguish Energycle: engineering customization (we adapt equipment to your materials, not vice versa), responsive technical support (English-speaking engineers, not just sales staff), and proven performance with challenging materials like oily LDPE and heavily printed films. We back our equipment with processing trials, transparent ROI projections, and comprehensive after-sales support—ensuring your investment delivers the performance we promise.