În domeniul reciclării plasticului, Standard Premium Mașini de granulat din plastic exemplifică eficiența și performanța superioară. Aceste mașini robuste sunt proiectate meticulos pentru a transforma diverse materiale plastice în fulgi sau resturi uniforme, servind drept componentă critică în sistemele complete de reciclare, inclusiv spălarea sticlelor PET și liniile de reciclare a foliei de plastic.

Principiul de funcționare

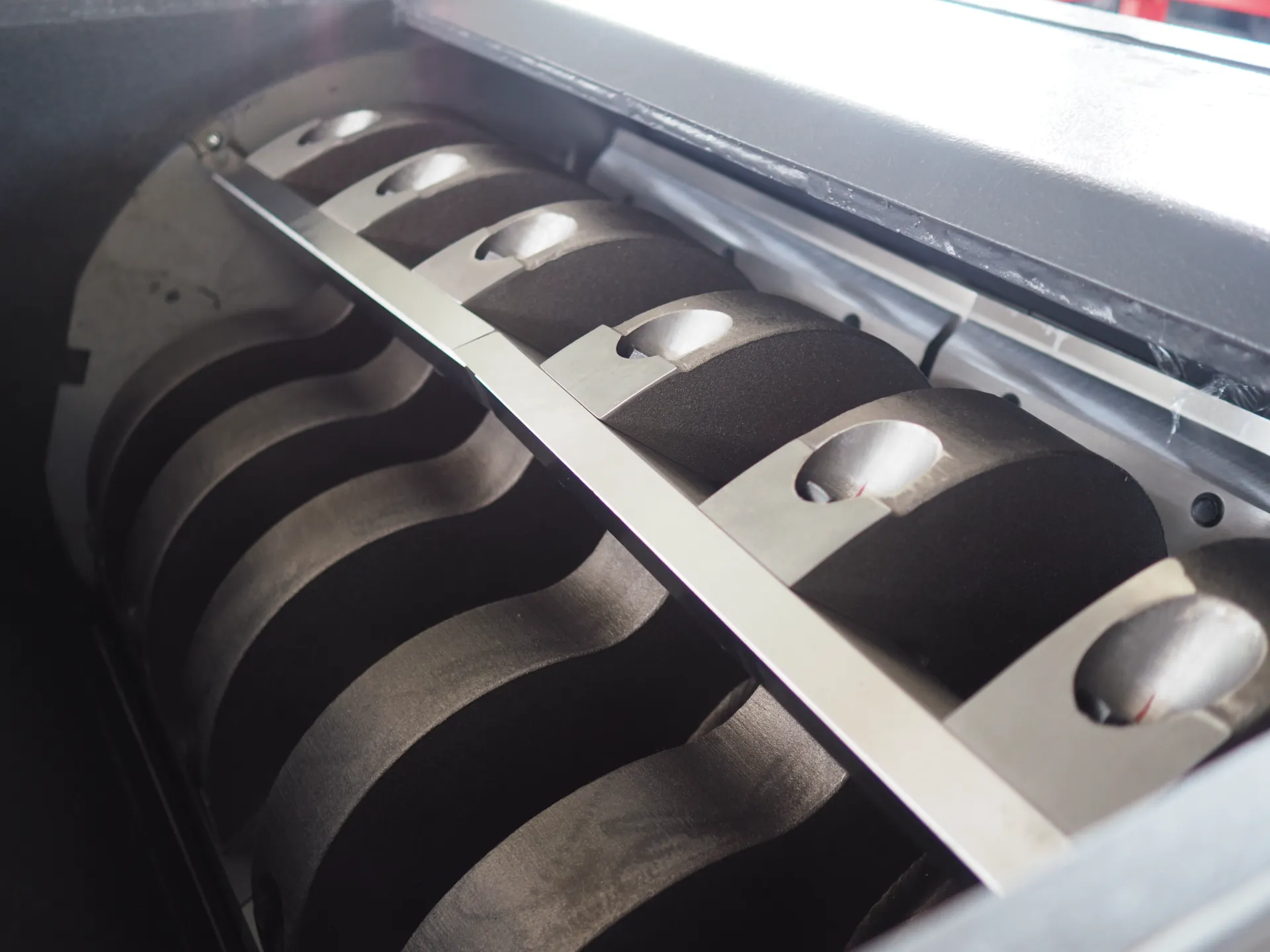

În centrul acestor granulatoare premium se află un rotor deschis echipat cu cuțite rezistente. Configurate într-o formă de tăiere cu foarfecă dublă sau în formă de V, aceste cuțite colaborează cu lame staționare din camera de tăiere. Deoarece rotorul funcționează la viteze mari, materialul plastic este supus unei tăieri continue până când atinge dimensiunea dorită pentru a trece printr-un filtru cu sită, asigurând o calitate constantă a granulelor.

Specificații tehnice

- Cuțite: Rotorul și cuțitele staționare sunt fabricate din oțel D2 cu conținut ridicat de carbon și crom, renumit pentru durabilitatea sa excepțională.

- Filtru ecran: Sunt disponibile filtre de sită personalizabile, cu dimensiuni cuprinse între 10 mm și 100 mm, permițând un control precis asupra dimensiunii granulelor de ieșire.

- Acces hidraulic: Camera de tăiere dispune de acces asistat hidraulic, facilitând reglajele și întreținerea simplă a cuțitului.

- Compatibilitatea materialelor: Aceste granulatoare sunt experte în procesarea diverselor materiale plastice, inclusiv sticle, folii și materiale plastice rigide de mici dimensiuni.

Specificații model

| Model | Diametrul rotorului | Lățimea rotorului | Viteză de rotație | Putere aprox. | Putere motor |

|---|---|---|---|---|---|

| RTM600 | ⌀450 mm | 600 mm | 400-600 rpm | 300 kg/h | 37 kW |

| RTM800 | ⌀500 mm | 800 mm | 400-600 rpm | 600 kg/h | 45 kW |

| RTM1000 | ⌀600 mm | 1000 mm | 400-600 rpm | 900 kg/h | 75 kW |

| RTM1200 | ⌀700 mm | 1200 mm | 400-600 rpm | 1200 kg/h | 90 kW |

Aplicații

Aceste granulatoare versatile sunt ideale pentru procesarea:

- Sticle de plastic: Reducerea eficientă a sticlelor PET la granule pentru reciclare.

- Folii de plastic: Manipularea cu precizie a peliculelor de diferite grosimi.

- Materiale plastice rigide: Prelucrarea ușoară a componentelor mici din plastic rigid.

Pentru o flexibilitate operațională sporită, sunt disponibile modele de granulatoare umede din plastic. Acestea sunt dotate cu etanșări din cauciuc și un furtun de admisie a apei pentru răcirea lamei în timpul funcționării, gestionând eficient generarea de căldură și menținând eficiența de tăiere.

Concluzie

Investiții în Mașini de granulat plastic standard premium înseamnă angajamentul de a spori eficiența și calitatea superioară în operațiunile de reciclare a plasticului. Construcția lor robustă, caracteristicile avansate și adaptabilitatea asigură economii pe termen lung și o productivitate sporită.

Garanție și asistență

Fiecare mașină vine cu o garanție limitată de 1 an. Echipa noastră dedicată de asistență este disponibilă pentru a răspunde oricăror întrebări sau nelămuriri, asigurând funcționarea neîntreruptă.

Notă: Sunt disponibile opțiuni de personalizare pentru a îndeplini cerințe operaționale specifice. Pentru informații detaliate și întrebări, vă rugăm să ne contactați direct.