Решења за помоћне системе

Помоћна опрема компаније Energycle — сушачи, перачи, сепаратори, чилери и још много тога — одржава вашу линију за рециклажу бржом, чистијом и паметнијом.

Зашто додавати помоћне системе?

+30 % пропусност

Континуирани проток са мање застоја.

Чистоћа до 99,9 %

Прецизно одвајање и чишћење повећавају вредност пахуљица.

‑70 % Лабуристи

Аутоматизација смањује ручно руковање и грешке.

Безбедније радно место

Затворено, аутоматизовано руковање оштрим, врућим или гвозденим опасностима.

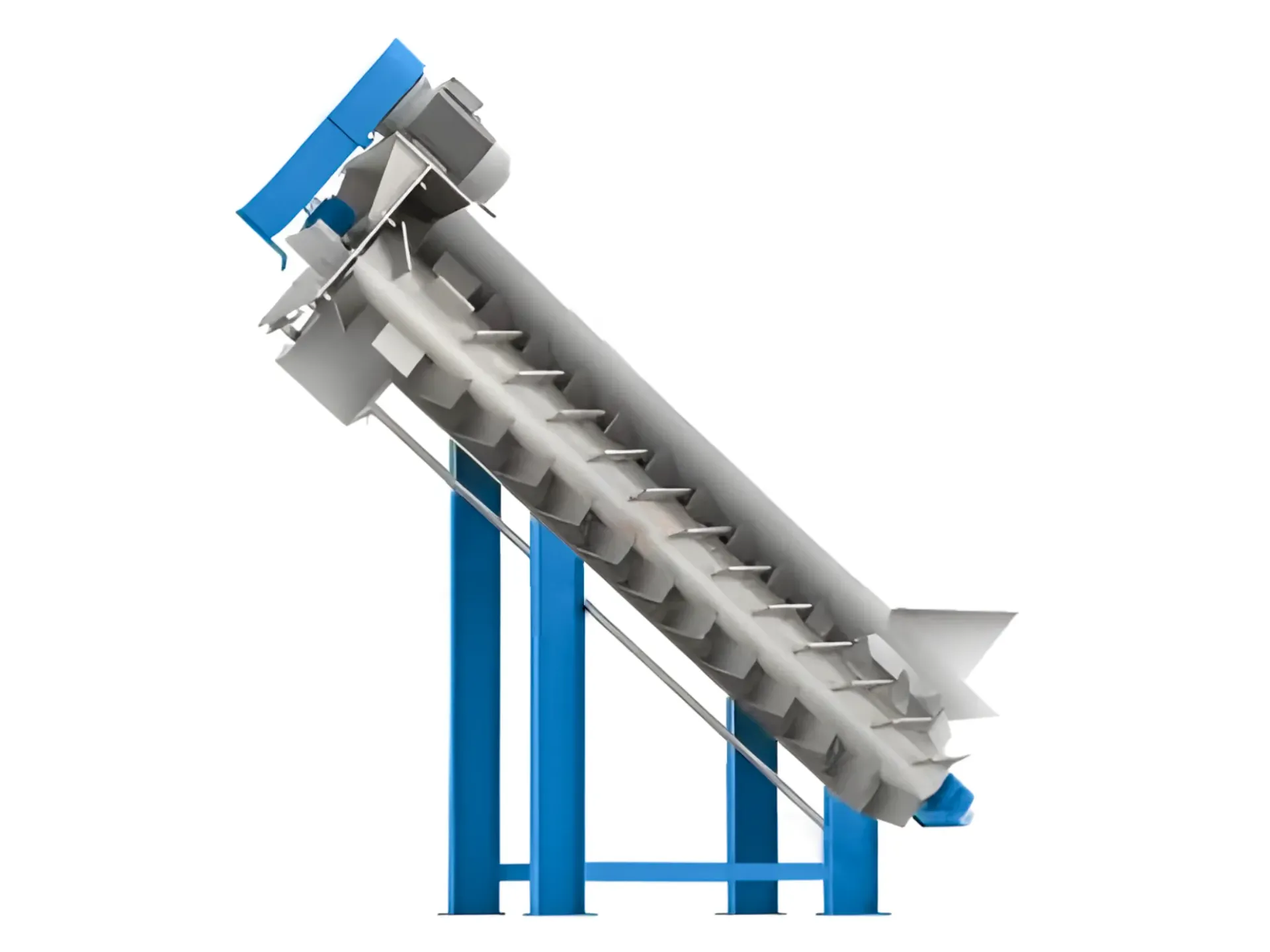

Брза фрикциона перач

Ротор од преко 1000 обртаја у минути чисти љуспице уз штедњу воде — повећава чистоћу PET и PE пре испирања.

Дизајн воденог млаза

Стратешки млазњаци смањују потрошњу и до 30%.

Модели до 2 т/х

Скалабилни капацитети са CE ознаком.

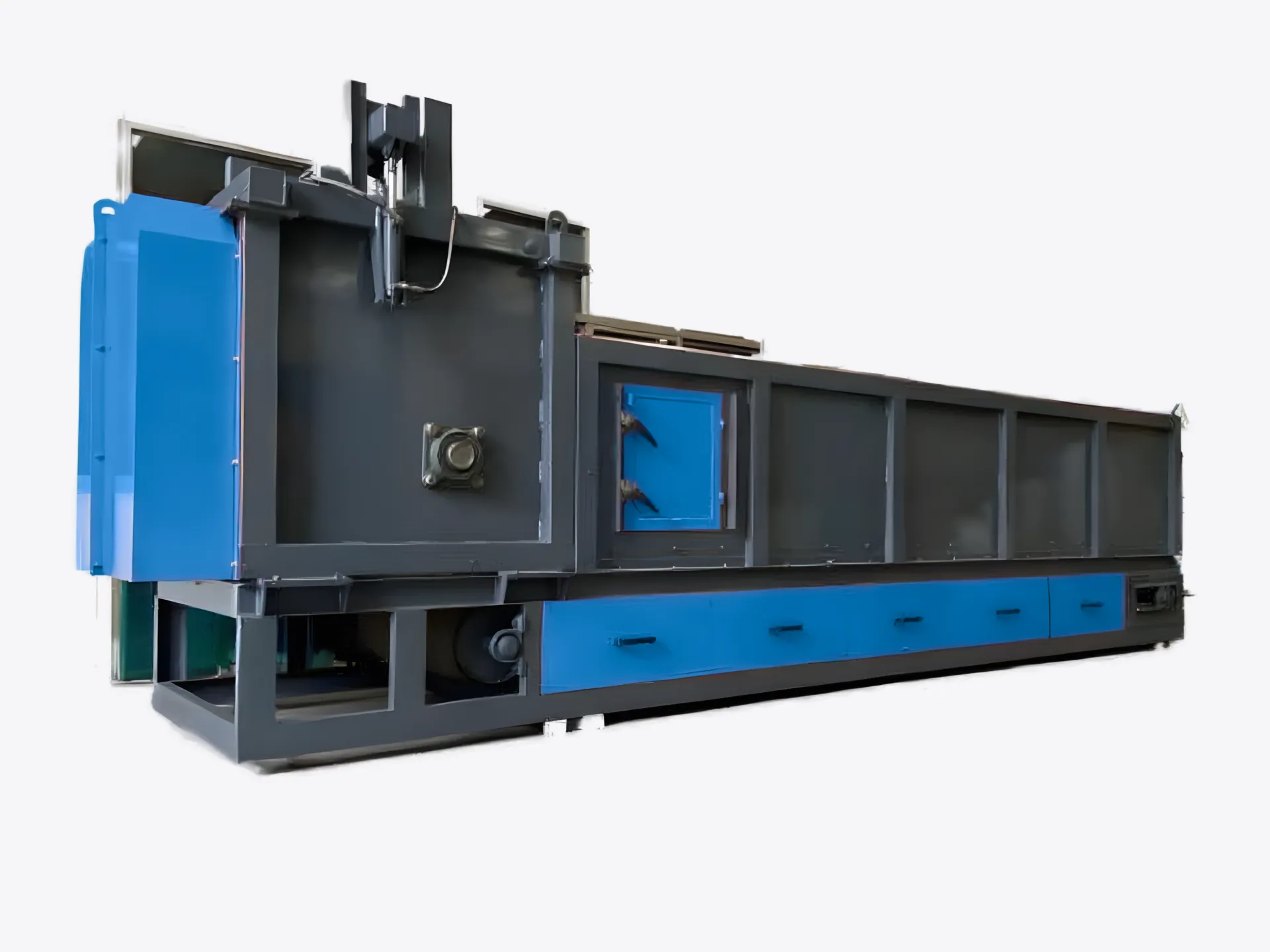

Самопражњећи магнетни сепаратор

Магнет преко каиша са аутоматским затегнутим каишем за уклањање обојених метала — штити брусилице и екструдере.

Ширина траке 800 мм

Погодно за транспортере до 0,8 м.

Самочистећи каиш

Нема ручног уклањања отпада, максимално се повећава време непрекидног рада.

Вертикална мешајућа сушара

Брзо мешање и сушење у једном бубњу — двослојна изолација и тајмер од 0 до 30 минута одржавају уједначену боју и ниску влажност.

Заменске сечива гранулатора

Ножеви SKD‑11 на лагеру — брза замена одржава висок проток.

Средство за уклањање влажних етикета са боца

Скида и испира етикете са ПЕТ боца у једном кораку, ефикасност >95 %.

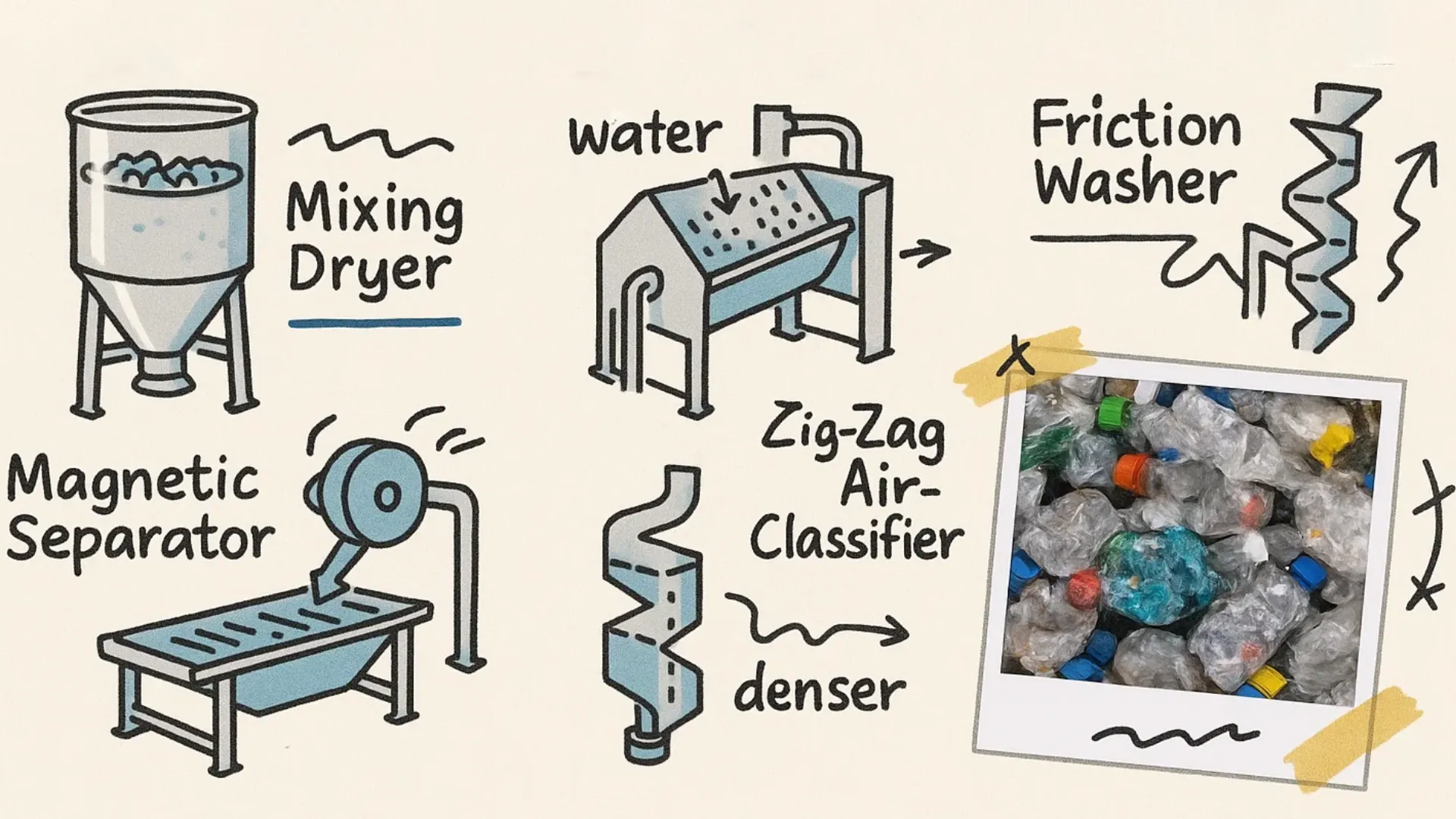

Цик-цак ваздушни класификатор

Ваздушни стуб заснован на густини одваја лагане филмове и прашину од тешког рециклираног материјала.

Резервоар за сепарацију са судопером и пловком

Исперите, одвојите и уклоните брус са теже пластике попут ПЕТ/ПВЦ-а у једној јединици.

Индустријски чилер са ваздушним хлађењем

Енергетски ефикасно хлађење (уштеда енергије до 30 %) за линије за калуповање и прање.

Спремни да надоградите своју линију?

Разговарајте са нашим инжењерима како бисте изабрали прави помоћни пакет — прилагодићемо модуларно решење за ваше постројење.

Затражите брзу понуду