Индустријски системи за сушење рециклаже пластике

Напредна технологија уклањања влаге пројектована за максималну ефикасност, прецизну контролу и врхунски квалитет рециклираног материјала.

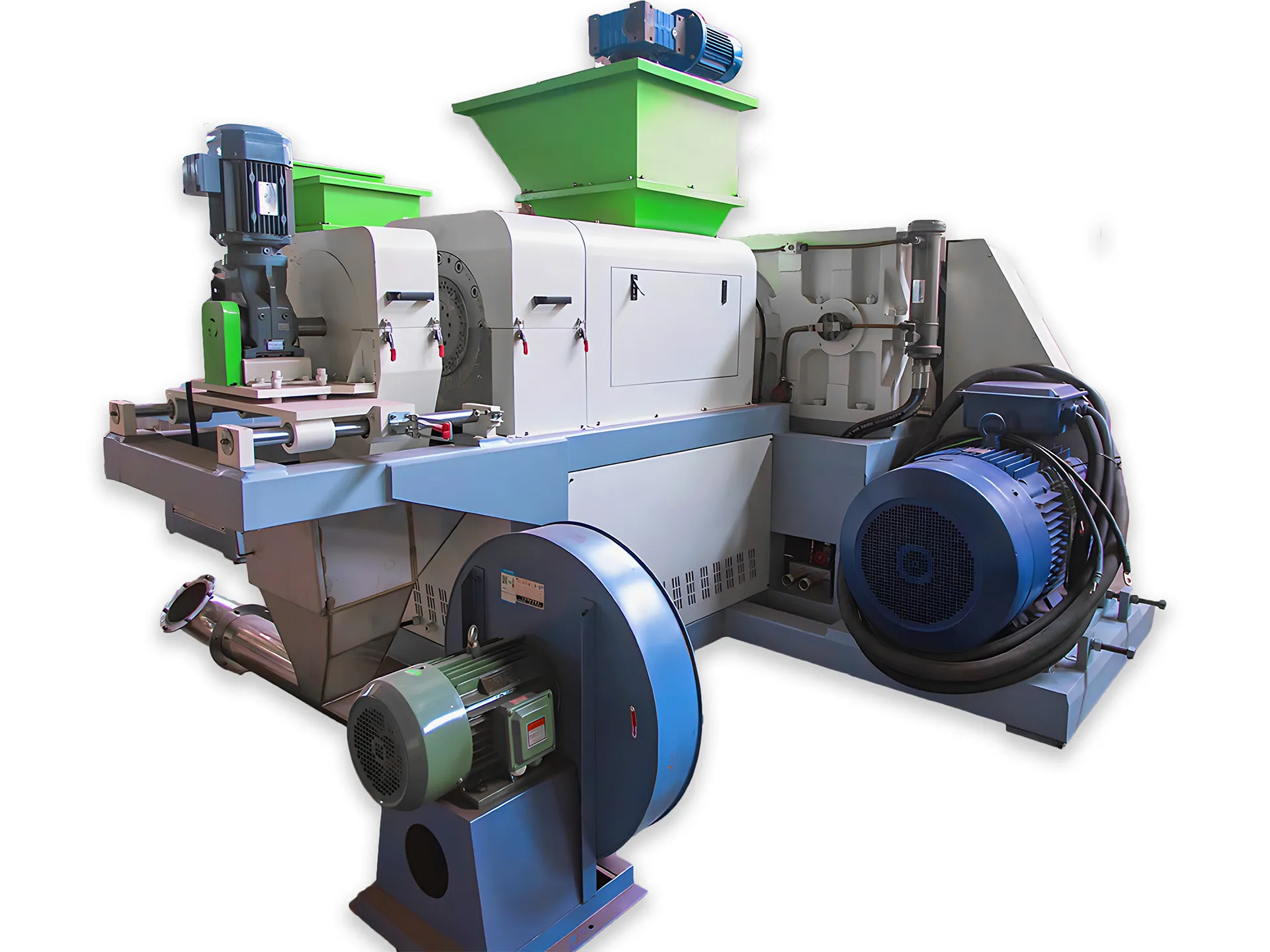

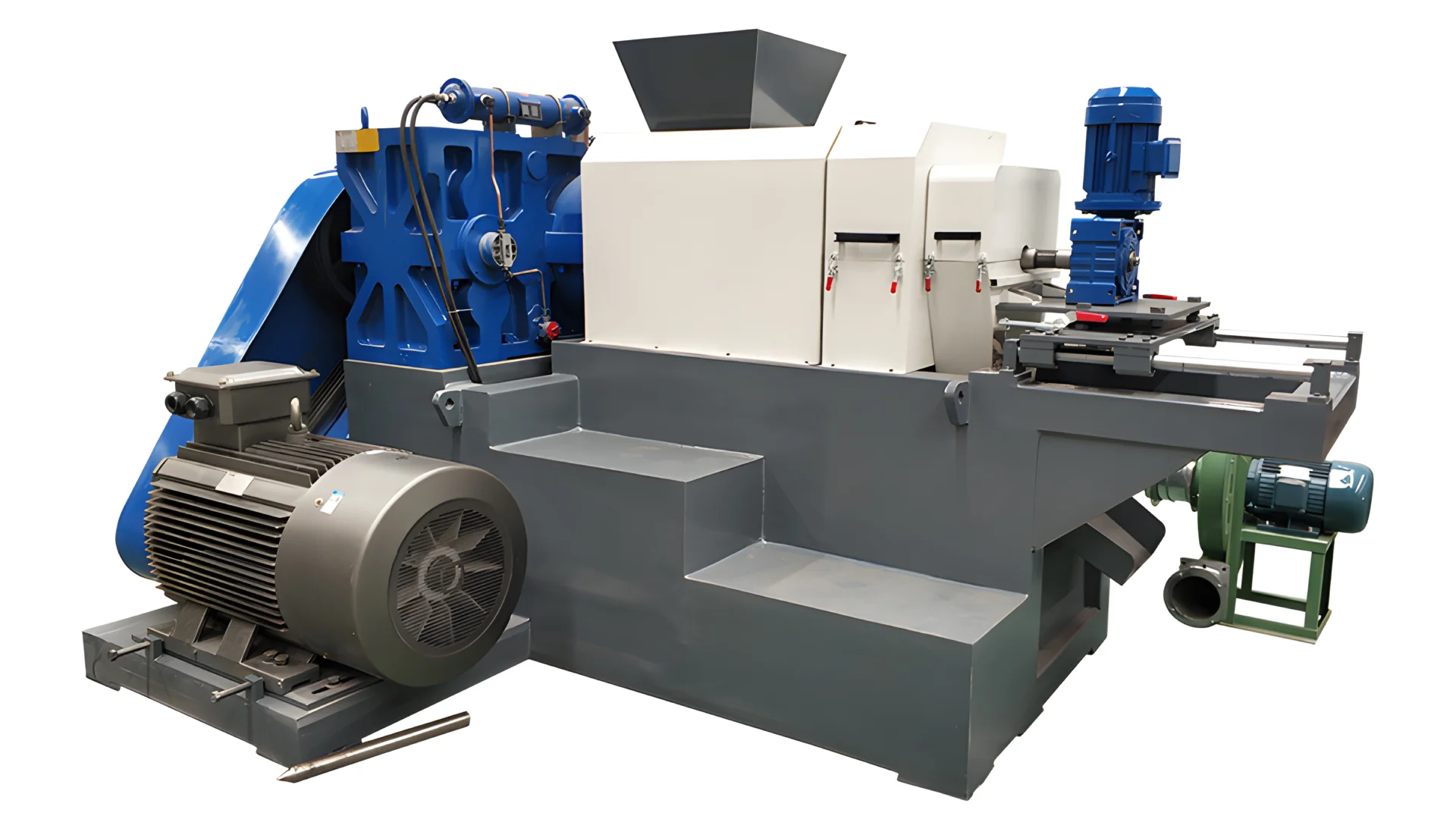

Високо ефикасно индустријско сушење

Наши напредни системи за сушење су посебно пројектовани за постројења за рециклажу пластике која захтевају максималне перформансе и проток. Са капацитетима од 100 кг/х до 2.000 кг/х, ови системи ефикасно уклањају влагу из пахуљица, млевеног материјала и пелета како би постигли водеће нивое сувоће у индустрији.

Направљени од компоненти индустријског квалитета и дизајнирани за рад 24/7, наши системи пружају конзистентне резултате чак и у најзахтевнијим производним окружењима, осигуравајући да ваши рециклирани материјали испуњавају највише стандарде квалитета.

Прецизна контрола влаге

Постигните ниво влажности чак 2% помоћу наше напредне технологије сушења, обезбеђујући оптимална својства материјала за висококвалитетне крајње производе.

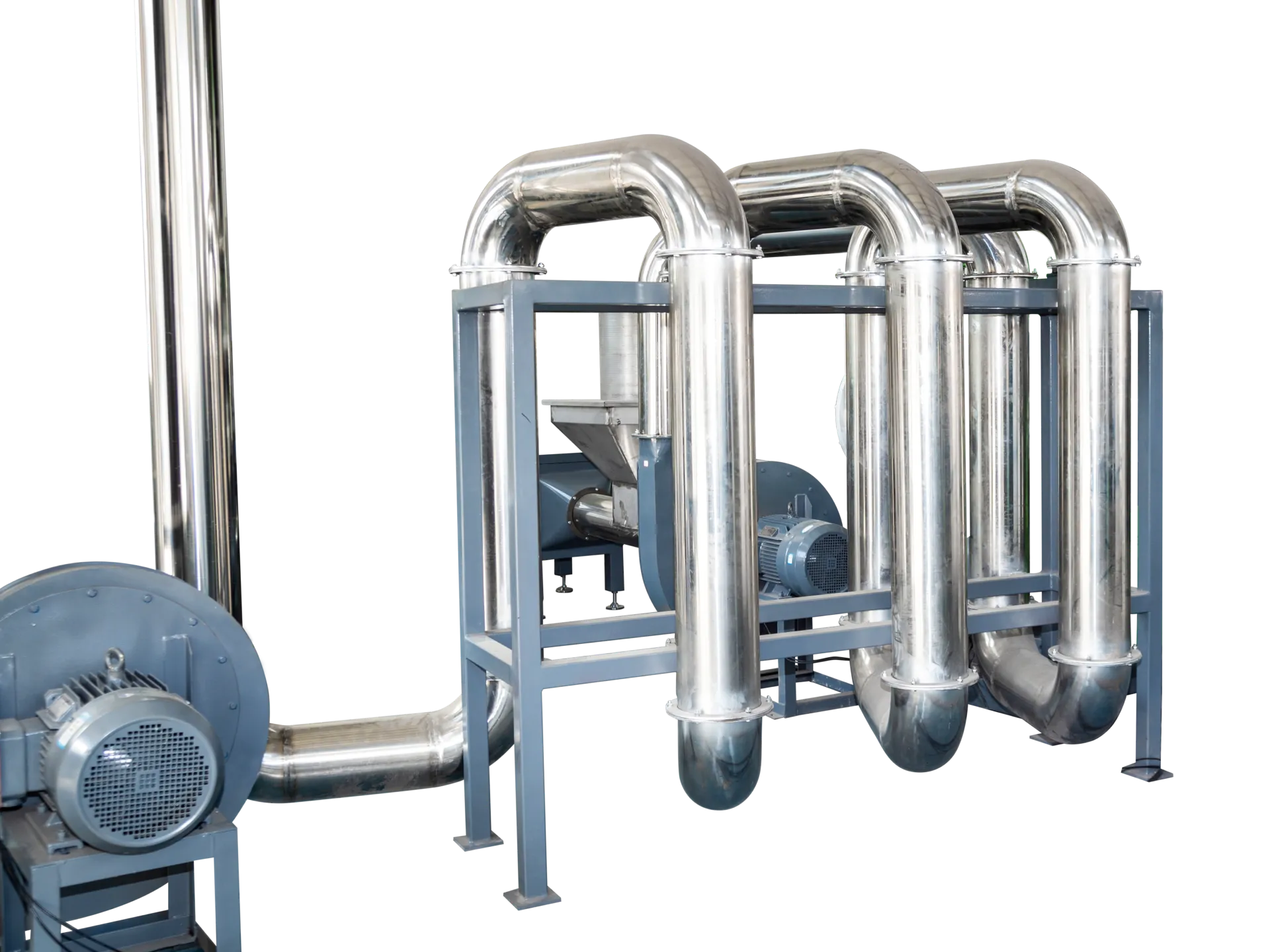

Енергетски ефикасна обрада

Наши иновативни системи за рекуперацију топлоте и технологија изолације смањују потрошњу енергије до 40% у поређењу са конвенционалном опремом за сушење.

Напредна технологија сушења

Наши системи користе вишеструке технологије сушења оптимизоване за различите врсте пластике и нивое контаминације, обезбеђујући максималну ефикасност за ваш специфични процес рециклаже.

Вишестепена обрада

Комбиновано механичко и термичко сушење за оптимално уклањање влаге из PET, PE, PP, PS и других полимера.

Прецизна контрола температуре

Подесиви температурни распон од 60°C до 180°C са тачношћу од ±1°C за обраду специфичну за материјал.

Компатибилност са више полимера

Ефикасно обрађујте PET, PE, PP, PS, ABS, PA, PC и друге полимере са прилагодљивим подешавањима за сваку врсту материјала и фактор облика.

Обрада великог капацитета

Доступно у више конфигурација са капацитетом протока од 100 кг/х до 2.000+ кг/х како би се задовољиле ваше производне потребе.

Мерљиве пословне користи

Већа вредност материјала

Остварите премиум цене за рециклиране материјале са садржајем влаге и до 2%.

Нижи оперативни трошкови

Смањите потрошњу енергије до 40% помоћу наших ефикасних система за рекуперацију топлоте.

Повећане стопе производње

Повећајте проток до 30% у поређењу са конвенционалним системима за сушење.

Смањени проблеми низводно

Елиминишите проблеме обраде повезане са влагом у операцијама екструзије и обликовања.

Паметни систем управљања

Аутоматизација заснована на PLC-у са 10-инчним HMI екраном осетљивим на додир пружа праћење у реалном времену, евидентирање података и могућности даљинског приступа за оптималну контролу процеса.

Свеобухватна услуга

Глобална техничка подршка, програми превентивног одржавања и тимови за брзо реаговање обезбеђују максимално време рада и оперативну ефикасност.

Оптимизујте свој процес рециклаже

Контактирајте наш инжењерски тим за персонализовану препоруку система на основу ваших специфичних потреба за материјалом, обима производње и ограничења објекта.

Захтевајте техничке консултације