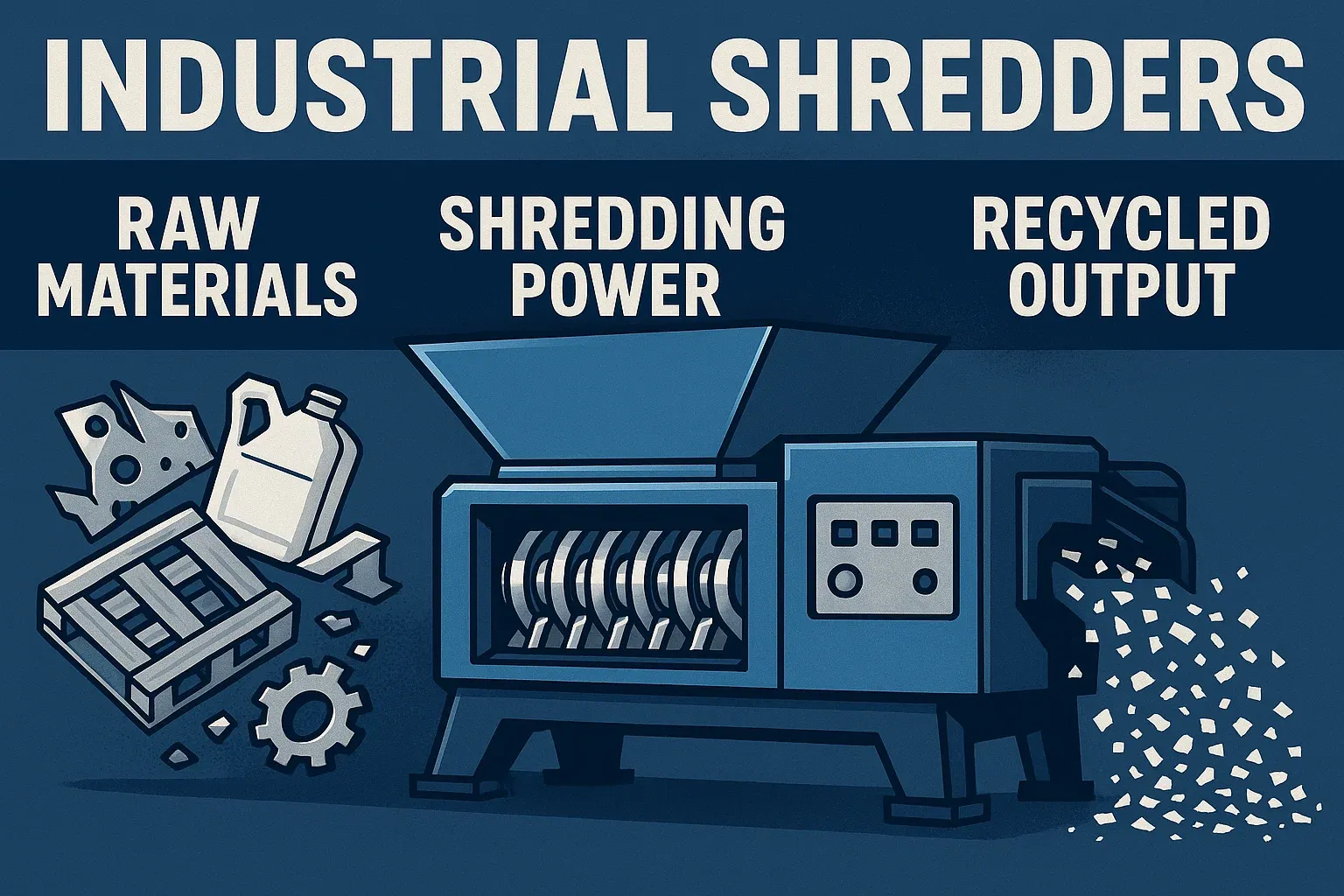

Hvad er en industriel makulator?

En industriel kværn er en kraftfuld maskine, der er specielt designet til at nedbryde store, seje eller blandede materialer til mindre, mere håndterbare stykker. Disse kværne håndterer store genstande og vanskeligt affald, hvilket gør affald lettere at bearbejde, genbruge og håndtere. Industrielle kværne, der typisk fungerer som det første trin i affaldsbehandling, reducerer affaldsmængden betydeligt og beskytter udstyr, der bruges i senere forarbejdningsfaser.

Hvordan fungerer en industriel makulator?

1. Kernefunktion: Lav hastighed, højt drejningsmoment

De fleste industrielle makulatorer kører ved lave rotationshastigheder (mellem 3,6 o/min og ca. 130 o/min), men genererer ekstremt højt drejningsmoment. Denne kombination gør det muligt for makulatorer at rive, klippe eller knuse hårde, uforudsigelige materialer effektivt. I modsætning til præcisionsskæring er makulatorer afhængige af rå kraft til at håndtere forskellige materialer såsom fast kommunalt affald og byggeaffald. Det høje drejningsmoment forhindrer blokeringer og stop, hvilket muliggør kontinuerlig drift, mens den lave hastighed hjælper skærerne med at gribe og bearbejde materialer uden at forårsage brud, hvilket gør dem ideelle til indledende affaldsbehandling.

2. Nøglekomponenter

Industrielle kompostkværne har flere robuste komponenter:

- Rotorer og skærere: Kraftige rotorer udstyret med stærke klinger, kroge eller knive lavet af slidstærke materialer som koldarbejdsstål.

- Skærekammer: En kraftigt forstærket indkapsling, hvor makulering finder sted, designet til at modstå intense mekaniske kræfter.

- Skærme (valgfrit): Nogle kværne har sigter under rotorerne for at kontrollere den maksimale partikelstørrelse (typisk 20 mm til 100 mm). Disse sigter hjælper med at styre partikelstørrelsen til efterfølgende håndtering, selvom de ikke skaber særlig ensartede partikler.

- Hydraulisk cylinder (valgfrit): Enkeltakslede kompostkværne har ofte en hydraulisk cylinder til at skubbe materialer vandret ind i skæreområdet, hvilket forbedrer behandlingseffektiviteten for store eller lette materialer.

- Driv- og styresystemer: Kraftige motorer, reduktionsgear og sikkerhedsfokuserede elektriske styresystemer sikrer sikker og effektiv drift.

3. Typer af industrielle makulatorer

Makulatorer findes i flere varianter, der hver især er egnet til specifikke opgaver:

- Enkeltaksel-kompostkværne: Én rotor med roterende skær mod stationære knive, hvilket giver en relativt ensartet partikelstørrelse gennem en integreret sigte.

-

Flerakslet kompostkværne:

- Dobbeltakslede (skær) kompostkværne: To modsat roterende aksler trækker og river materialer i strimler, ideelt til store genstande.

- Fireakslede kompostkværne: Fire aksler giver aggressiv neddeling, hvilket resulterer i mindre, mere ensartede stykker i én arbejdsgang.

- Pierce-and-Tear-makulatorer: Udstyret med langsomt bevægelige aksler og krogede knive, kværner de effektivt elastiske og uregelmæssigt formede materialer.

- Kværne: Højhastighedsroterende aksler eller tromler udstyret med klinger eller hamre til kombineret skæring og slibning, egnet til plast, træ og organiske materialer.

-

Specialiserede makulatorer:

- Tromlekværne: Brug roterende tromler med klinger eller hamre til storskalabehandling af organisk affald og træ.

- Flishuggere: Specielt designet til haveaffald, hakker de hurtigt grene og træ til små flis.

- Hammermøller: Brug svingende hamre, der roterer hurtigt, til at pulverisere materialer til finere partikler.

Karakteristika for makuleret materiale

Materialet, der produceres af makulatorer, indeholder typisk:

- Stor, variabel størrelse: Spænder bredt fra 20 mm til 100 mm eller større, i modsætning til granulatorer, som producerer mindre, ensartede partikler.

- Uregelmæssig form: Outputtet består normalt af ujævne strimler, klumper eller ru stykker, hvilket afspejler den aggressive makuleringsmetode.

- Lav ensartethed: Makulerede materialer varierer meget i størrelse og form, og inkluderer ofte støv og fint stof, og kræver generelt yderligere forarbejdning for præcisionsbrug.

Materialer og anvendelser

Typisk forarbejdede materialer:

Industrielle makulatorer håndterer forskellige materialer, herunder:

- Dæk

- Metaller (aluminium, kobber, messing)

- Byggeaffald

- Træ (paller, træstammer)

- Plast (tromler, rør)

- Elektronisk affald (e-affald)

- Papir og pap

- Tekstiler og læder

- Mad- og farmaceutisk affald

- Møbler og gummi

- Datalagringsenheder (harddiske)

Almindelige anvendelser:

Industrielle kværne bruges primært til:

- Volumenreduktion: Formindskelse af storskrald for nemmere håndtering og omkostningseffektiv transport.

- Førstegangsgenbrug: Klargøring af materialer ved at nedbryde dem for at lette sortering og genbrug.

- Sikker destruktion: Sikker destruktion af følsomme dokumenter, defekte produkter eller dataenheder.

- Affaldsbehandling: Behandling af forskellige typer affald (kommunalt, medicinsk, farligt) før bortskaffelse eller videre behandling.

- Ressourcegendannelse: Udvinding af værdifulde materialer såsom metaller fra elektronikaffald eller gummi fra dæk.

Industrielle kværne er, på grund af deres alsidighed, pålidelighed og styrke, blevet uundværlige inden for affaldshåndtering, genbrug og ressourceudvinding, hvilket forbedrer miljømæssig bæredygtighed og driftseffektivitet betydeligt.