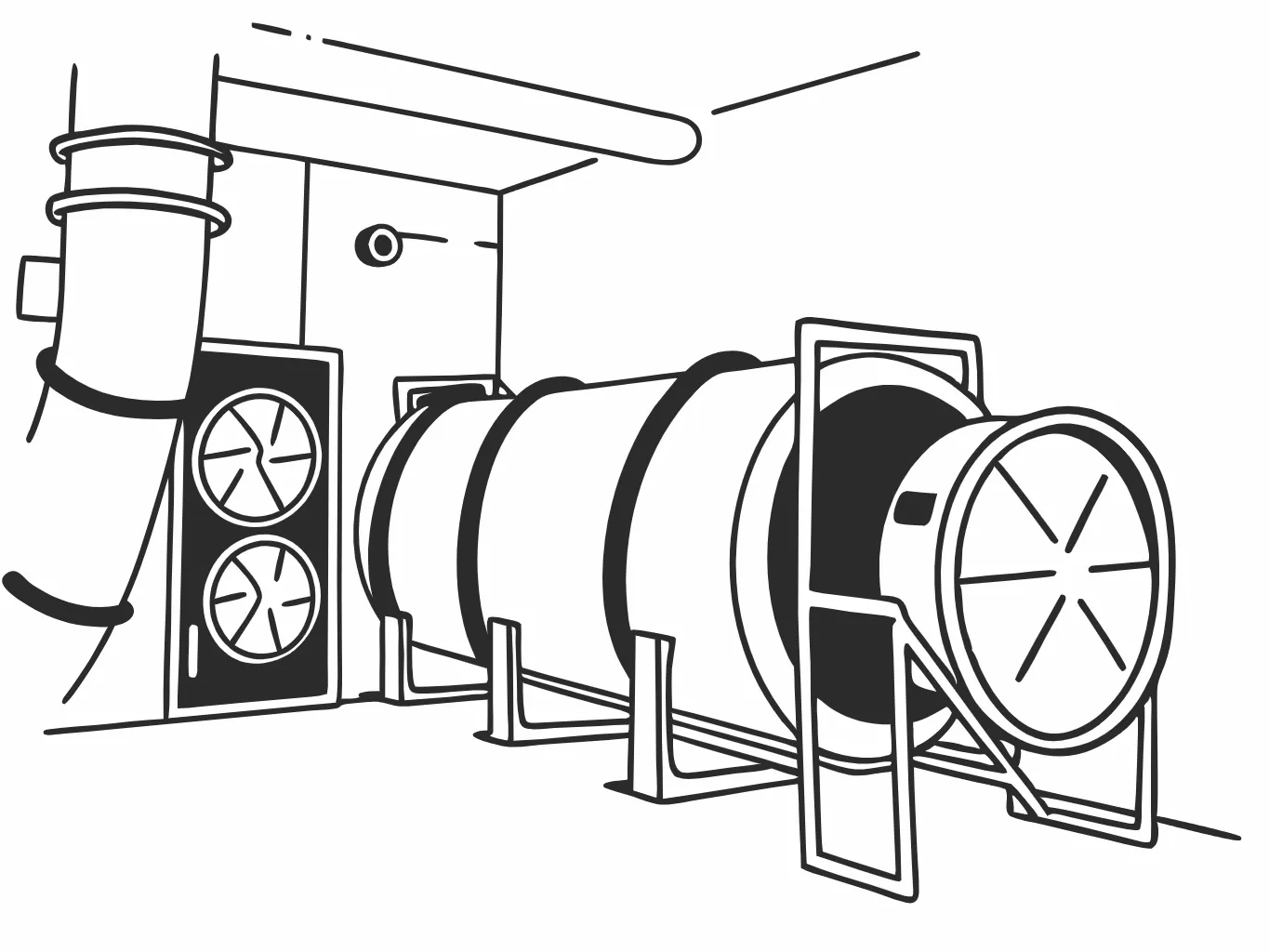

Secadores centrífugos en el reciclaje de plásticos: Impulsando la eficiencia y la sostenibilidad

En el panorama de reciclaje en rápida evolución de hoy, tanto los profesionales como los inversores están explorando continuamente tecnologías que mejoran la sostenibilidad y...