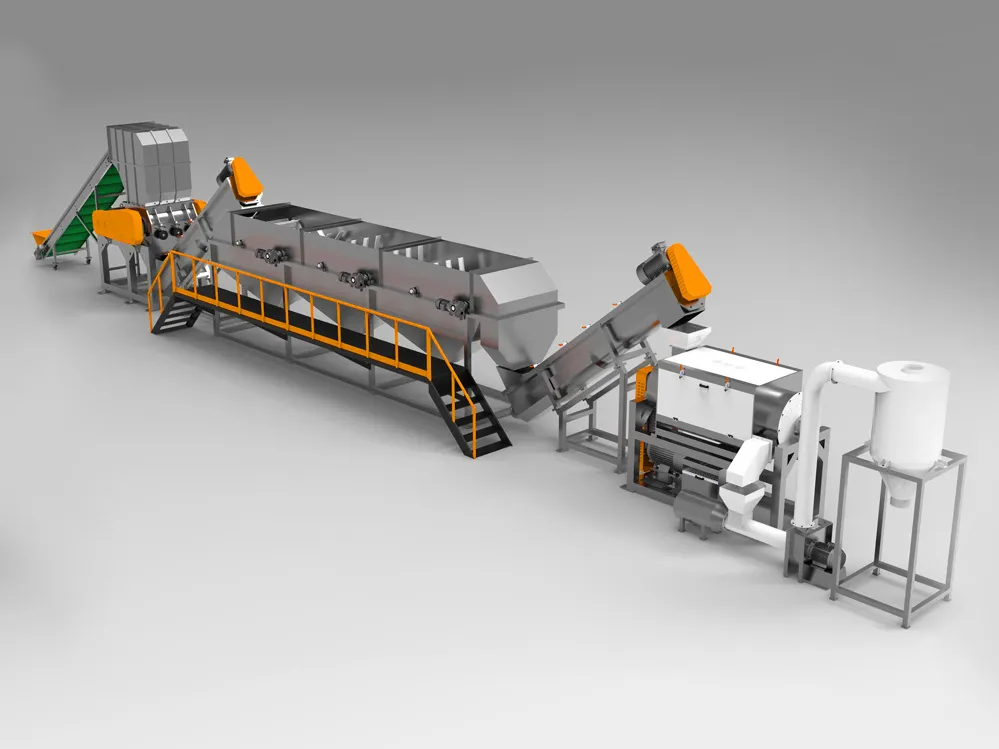

Tackling plastic waste is crucial for protecting our environment, and effective plastic recycling is key. We’re excited to introduce a truly innovative solution: the PP PE Film Shredding and Densifying Line. This advanced system transforms challenging bales of dirty PP/PE films into high-quality densified material, perfectly prepared for further chemical processing or pelletizing into reusable plastic granules. It’s a smarter way to recycle plastic film!

Example of densified material ready for pelletizing.

How It Works: Step-by-Step

- Shredding Power: The journey begins with our robust shredder, specifically designed to break down large, compacted bales of plastic films efficiently. The shredded pieces then move smoothly onto a conveyor belt, ready for the next vital step.

- Wet Granulation Precision: Next, the material enters the wet granulator. Here, high-speed rotating knives precisely cut the film into small, uniform flakes. An integrated screen ensures only flakes of the perfect size proceed, optimizing them for densification.

- Sink/Float Separation Purity: Cleanliness is key! The flakes are transferred to a sink/float separation tank. This clever process uses water density to separate valuable plastic film (which floats) from heavier contaminants (which sink), ensuring a pure feedstock.

- Squeezing and Densification Excellence: Finally, the clean, wet film enters the squeezer-densifier. Using a powerful screw press and controlled heating, this unit efficiently removes water and compresses the film into dense, irregular pellets (approx. 350-410 kg/m³ density), ready for their next life.

Key Features & Specifications

The densified material produced typically measures around 50 mm in length. Need smaller particles? No problem – an optional secondary granulator can easily be integrated into the line.

Discover the benefits of our multifunctional extrusion dryer technology:

- Dramatically reduces moisture content down to just 3% (from an initial ~30% for thin film).

- Increases the bulk density significantly, by up to 10 times.

- Effectively compacts the material for easier handling and storage.

We stand by our quality: all our recycling machines come with a 1-year limited warranty. Plus, we offer customization options to perfectly match your specific operational needs.

| Model | RTM-200 | RTM-500 | RTM-1000 |

|---|---|---|---|

| Operation (Personnel) | 2-3 | 2-3 | 2-3 |

| Installation Power (kW) | 160-200 | 200-240 | 400-450 |

| Knife Material | SKD11 | SKD11 | SKD11 |

| Capacity (kg/h) | 200 | 500 | 1000 |

Your Partner in Sustainable Recycling

A PP PE Film Shredding and Densifying Line represents a significant leap forward in műanyag újrahasznosítási technológia. By efficiently processing post-consumer or post-industrial plastic films, this system not only streamlines recycling operations but also makes a tangible contribution to reducing environmental impact. Embrace this advanced solution to enhance your recycling efforts and champion a truly circular economy for plastics.

Ready to Learn More? Let’s Talk!

Warranty Information:

All our recycling machines come with a comprehensive 1-year limited warranty for your peace of mind.

Interested in boosting your plastic film recycling capabilities? For the latest pricing, lead times, or to discuss customization options, please send us a message using the form below. We’re here to help!