Вести о рециклажи

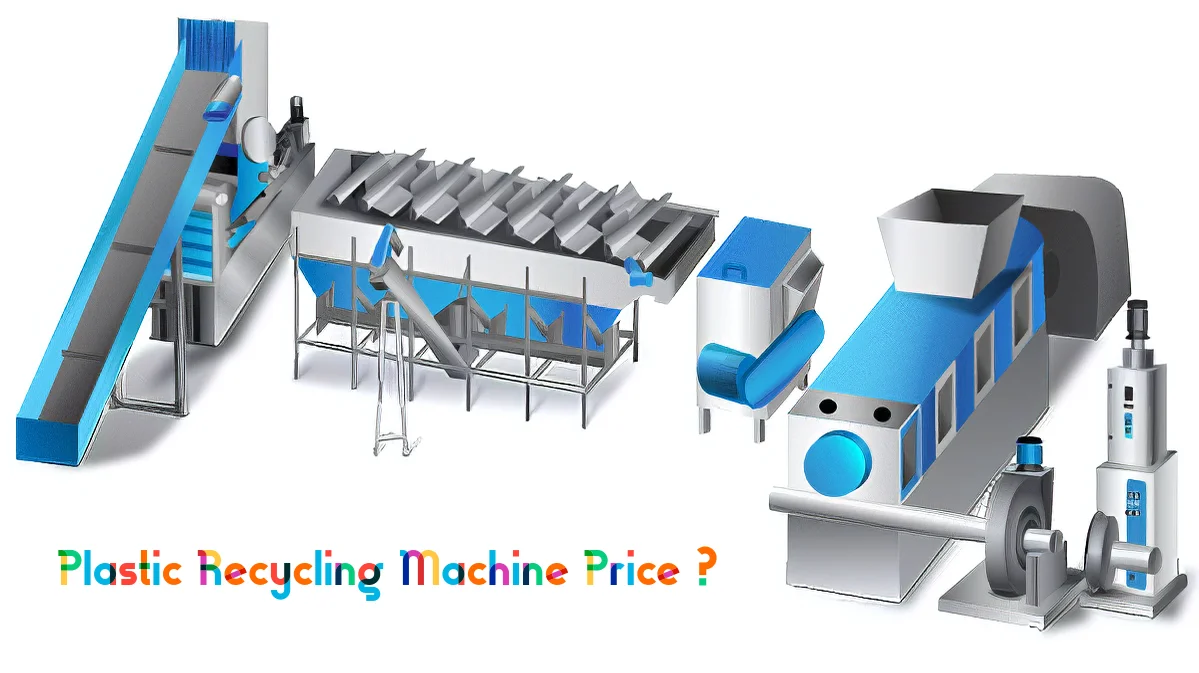

When it comes to PET bottle recycling, Rumtoo's industrial shredders are leading the way. These machines are specifically designed to handle the complexities of recycling plastic bottles, providing an efficient and reliable solution for plastic container recycling. Often referred to as PET bottle shredders or PET bottle grinders, Rumtoo's shredding technology is at the forefront of plastic waste management.

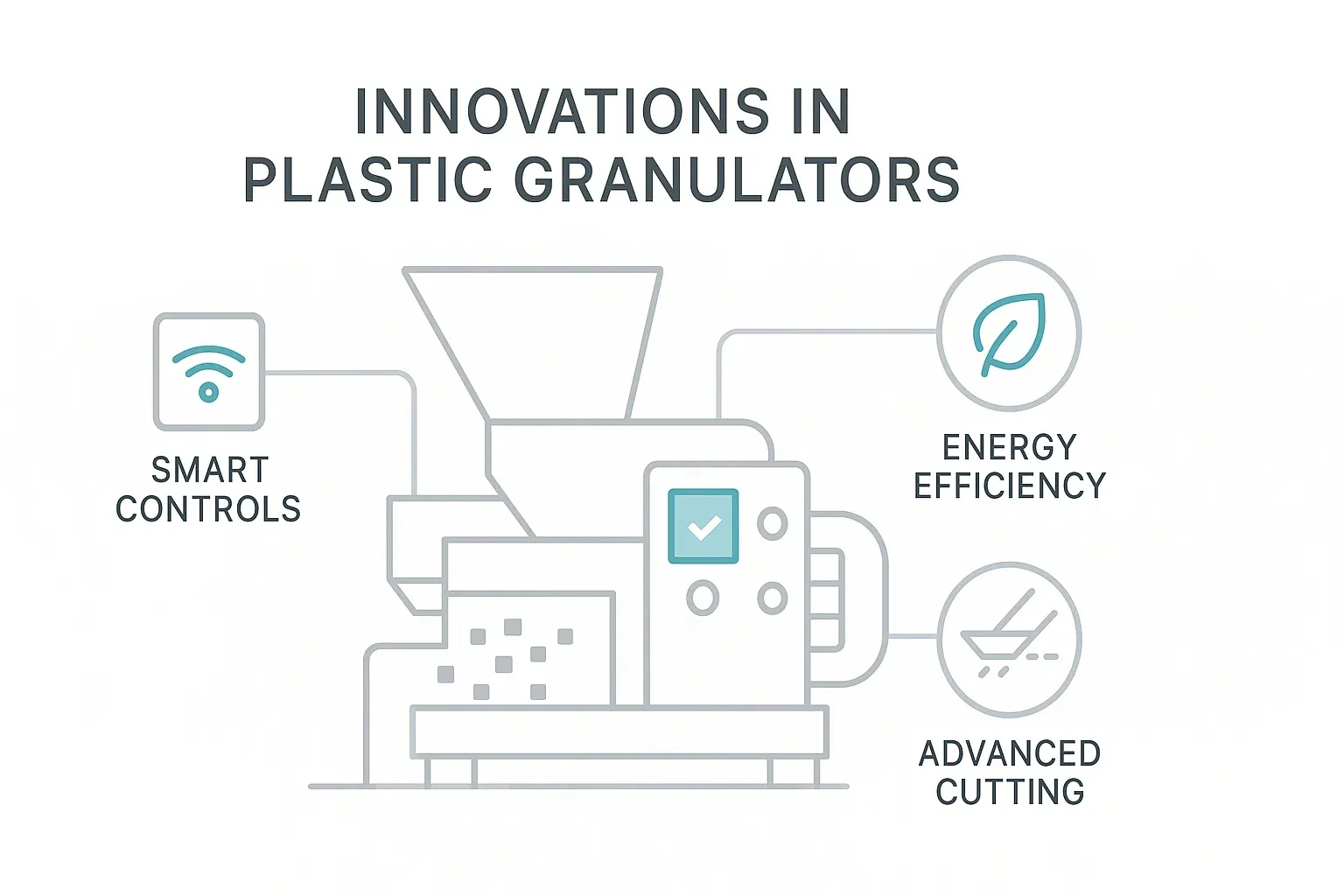

Увод у пластичне пелетизаторе

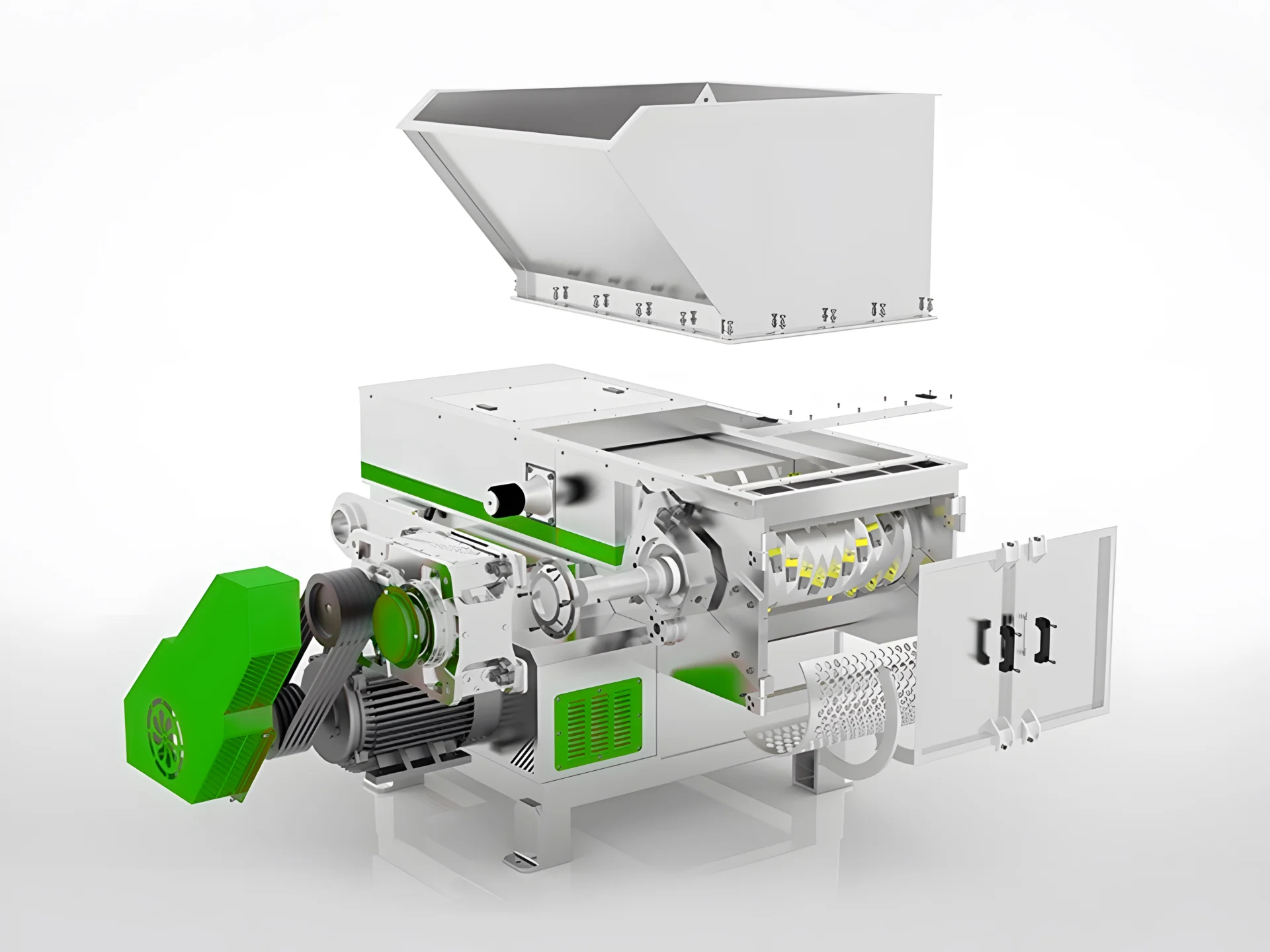

Пластични пелетизатор је кључна машина у индустрији рециклаже и производње, дизајнирана да трансформише пластични отпад у употребљиве пластичне пелете. Ове пелете служе као сировина за производњу нових пластичних производа, што га чини кључним играчем у промоцији одрживих пракси.

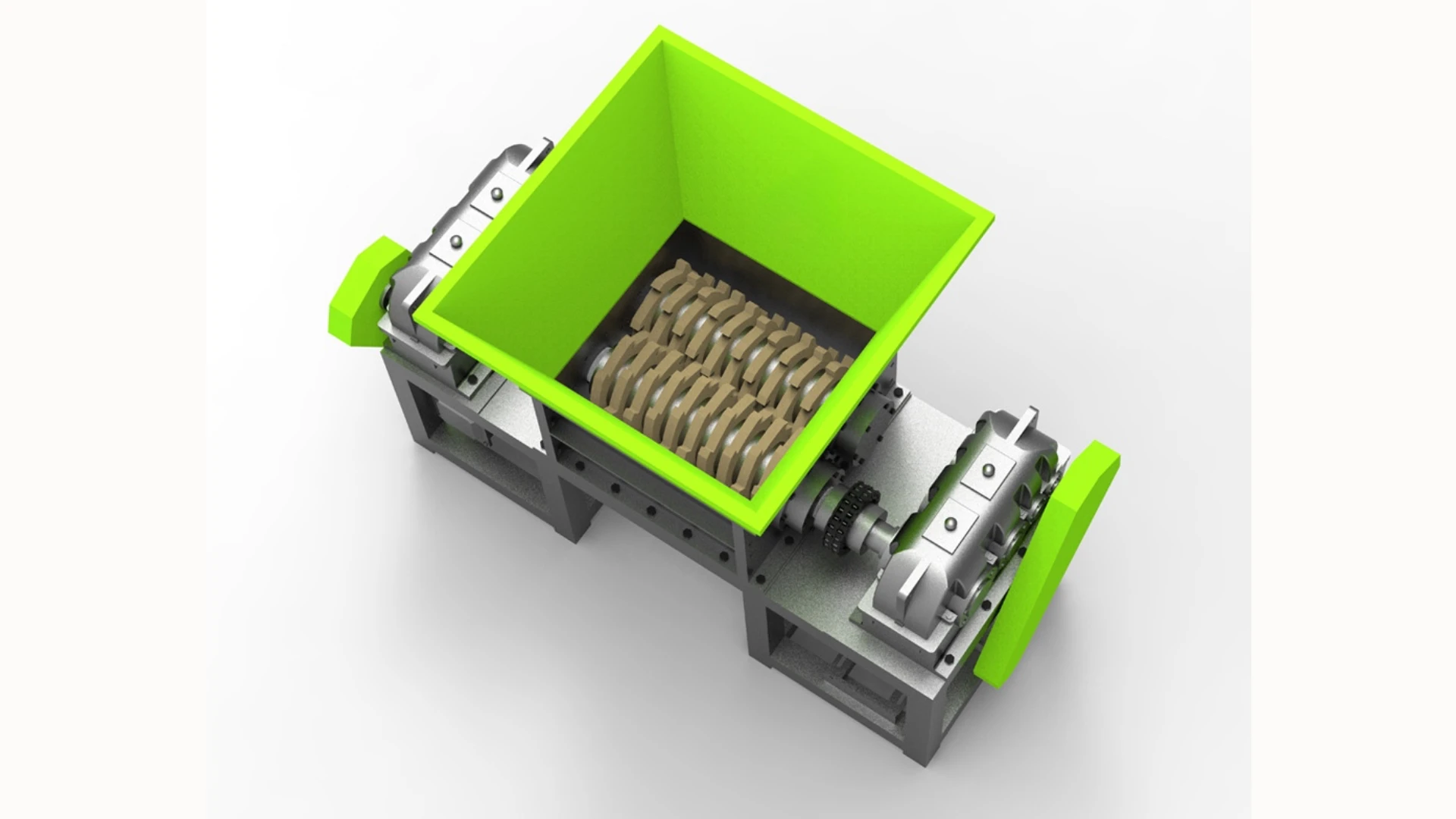

Пластични гранулатори играју кључну улогу у процесу рециклаже пластике, трансформишући пластични отпад у мале, униформне грануле које се могу поново користити у производњи нових пластичних производа. Да бисте осигурали да ваш пластични гранулатор ради са максималном ефикасношћу и да има дуг радни век, неопходно је спровести робусну рутину одржавања и благовремено решавати све проблеме.