Вести о рециклажи

Процеси рециклаже пластике за уобичајене смоле попут PET, HDPE и PP укључују више корака – од уситњавања и прања до сушења очишћене пластике. У завршним фазама, уклањање сваке капи влаге је кључно. Центрифугалне сушаре играју кључна улога у овој фази, осигуравајући да су пластичне пахуљице чисто и суво за поновну употребу у новим производима. Овај чланак се бави начином функционисања центрифугалних сушача, зашто су важни за материјале попут PET, HDPE и PP, и упоређује њихову ефикасност са традиционалним сушачима врућим ваздухом. сушење цеви системи. Такође ћемо размотрити како се ови сушари користе у великим индустријским постројењима у односу на мала предузећа и истаћи предности и разматрања при избору методе сушења.

To improve the efficiency of a PE film washing line, you need to focus on equipment upgrades, process optimization, and resource management. Here are the most effective ways to boost performance and reduce operational costs.

Modern PET bottle washing lines rely on centrifugal dryers to achieve the stringent moisture standards required for high-quality recycled PET flakes. These systems combine mechanical efficiency with advanced automation to deliver energy savings, material preservation, and operational reliability.

Plastic recycling plays a pivotal role in modern sustainability efforts, aiming to minimise waste and repurpose materials into new products. Among the various stages of the recycling process, одводњавање is crucial, as it removes water from washed plastics, preparing them for further processing.

У свету који је све више усмерен на одрживост, рециклажа ПЕТ флаша постала је кључни корак ка смањењу загађења пластиком и очувању ресурса. У сржи овог процеса лежи... Линија за прање ПЕТ флаша, специјализовани систем који чисти и припрема ПЕТ боце након потрошње за поновну употребу. Овај чланак истражује како се рециклиране ПЕТ боце трансформишу у вредне материјале, њихову примену у различитим индустријама и зашто је улагање у технологију прања ПЕТ боца неопходно за циркуларну економију.

This comprehensive guide delves into the customized selection of pet bottle washing lines, focusing on meeting different scale requirements by discussing the differences between small, medium, and large lines, and providing practical advice on choosing the right equipment based on business needs. The information is derived from extensive research into manufacturer specifications, industry practices, and recycling processes, ensuring a thorough understanding for businesses aiming to optimize their recycling operations.

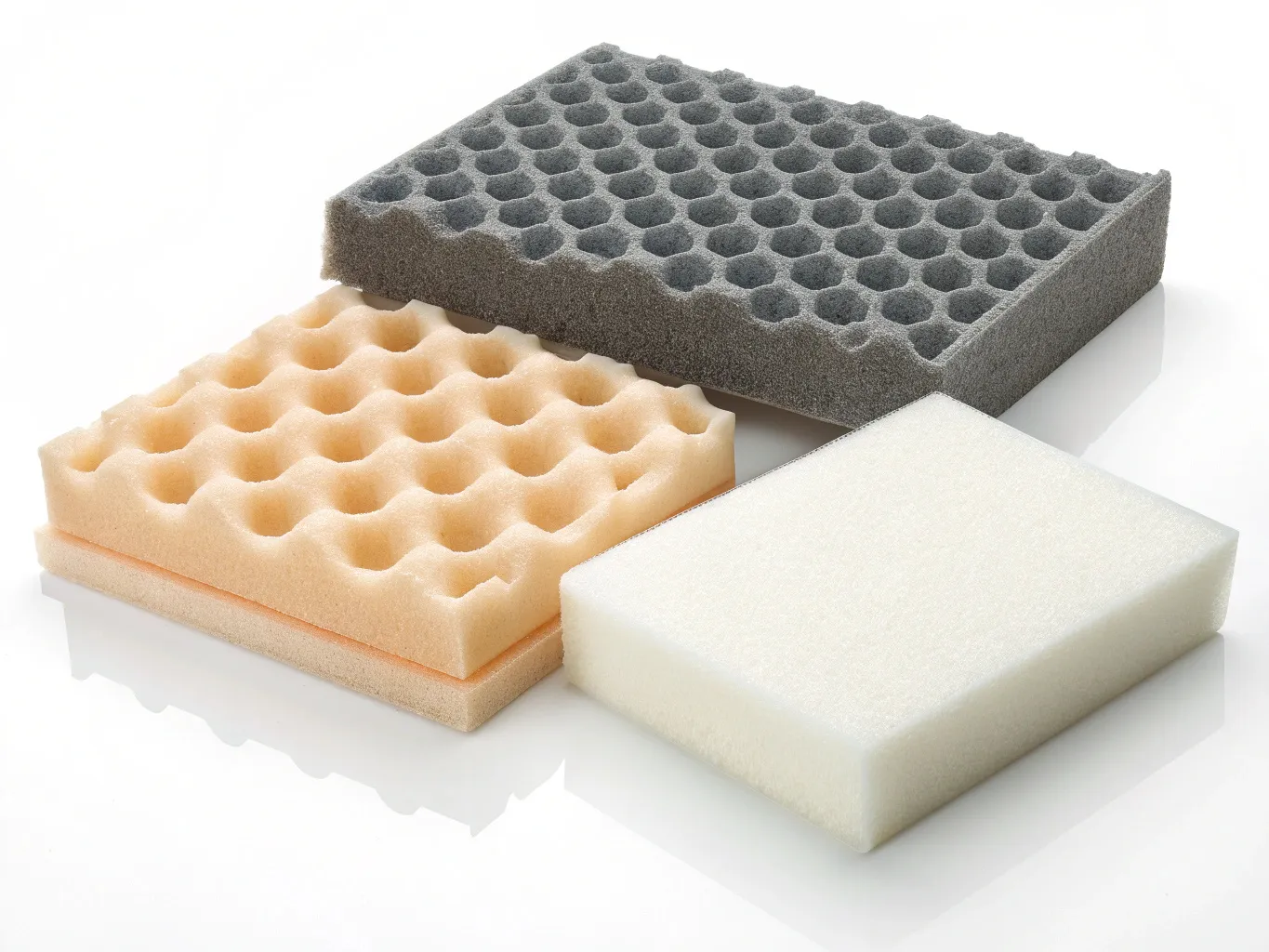

This article provides an in-depth exploration of the recycling processes for Expanded Polyethylene (EPE) и Expanded Polystyrene (EPS) foams, highlighting their similarities and differences based on current industry research and best practices. The aim is to inform recycling professionals, environmental advocates, and industry stakeholders about the practical feasibility, challenges, and sustainable opportunities associated with recycling these widely used materials.

If you're running a PET bottle washing line, you already know how crucial it is for turning used plastic into high-quality flakes ready for reuse. But let’s face it—keeping this equipment in top shape isn’t always easy. Regular maintenance is the key to avoiding costly downtime, extending the life of your machines, and ensuring your operation runs like a well-oiled machine. Here’s a practical, no-nonsense guide to keeping your PET bottle washing line in peak condition.

The PET bottle washing line process is a critical component of plastic recycling, transforming post-consumer PET bottles into high-quality PET flakes for reuse. This detailed analysis covers each step, compares cold and hot washing methods, and highlights environmental and economic benefits, ensuring a comprehensive understanding for both industry professionals and lay readers.

This guide provides a detailed exploration of selecting the appropriate PET bottle washing line for your recycling business, ensuring efficiency, quality, and cost-effectiveness. PET bottle washing lines are critical for transforming used polyethylene terephthalate (PET) bottles into clean PET flakes, which are then repurposed for various applications such as new bottles, textiles, and packaging materials. The process involves several stages, including debaling, sorting, washing, and drying, and the choice of line can significantly impact your operation’s success.

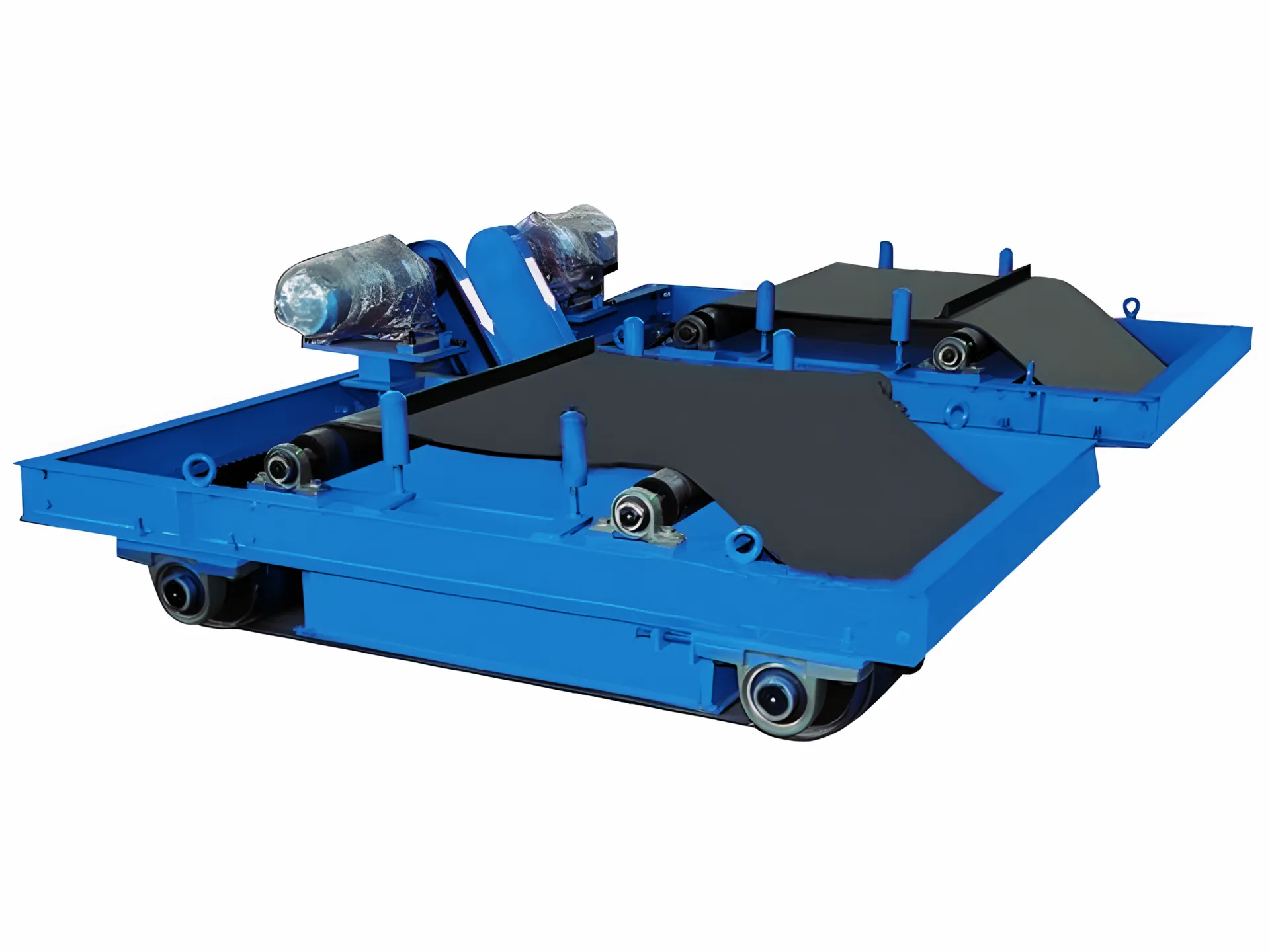

Suspended Self-Discharging Magnetic Separators are specialized industrial equipment designed to remove ferrous metals from conveyor belts. They are suspended above the conveyor and feature an automated self-cleaning mechanism, such as a continuously moving belt, to discharge captured metal into a collection bin or chute. This automation ensures uninterrupted operation, making them ideal for high-volume industrial processes.