Вести о рециклажи

Addressing the global challenge of plastic waste, polyethylene terephthalate (PET) stands out due to its widespread applications and recyclability. Efficient PET recycling systems are crucial for realizing a circular economy and reducing reliance on virgin resources. This article provides a professional overview of the core components of a PET recycling machine, elucidating how these essential modules work in concert to transform post-consumer PET materials into high-quality recycled feedstocks. We will delve into the equipment configurations of critical stages including pre-processing, washing, sorting, and extrusion pelletizing, briefly analyzing the technical specifications and performance metrics of each section. This aims to offer industry professionals a deeper understanding of the PET recycling process flow and equipment composition.

Foam recycling has become a critical component of sustainable manufacturing practices, particularly for industries dealing with expanded polystyrene (EPS) and other foam materials. Investing in foam recycling machinery offers manufacturers a dual advantage: reducing environmental impact and achieving significant cost savings. This analysis explores the costs, benefits, and strategic considerations for manufacturers contemplating such an investment.

What is PET Recycling and Why is it Important?

Polyethylene Terephthalate, commonly known as PET, is a type of plastic used extensively in packaging, particularly for beverages and food products. Recycling PET is vital for reducing plastic waste, conserving resources, and mitigating environmental impact. With increasing global awareness and regulatory pressure to move towards a circular economy, the demand for effective PET recycling solutions is on the rise.

Choosing the right PET recycling machine is a critical decision for businesses in the recycling industry. The right machine can improve efficiency, reduce costs, and ensure high-quality output. However, with so many options available, it can be challenging to determine which machine best fits your needs. This guide provides a comparative analysis of PET recycling machines to help you make an informed decision.

Understanding Sorting Machinery in Plastic Recycling

Sorting machinery in the plastic recycling industry plays a crucial role in classifying different types of plastic materials based on attributes such as color, density, and composition. These machines simplify the sorting process through advanced technologies and processes, ensuring optimal material recovery efficiency.

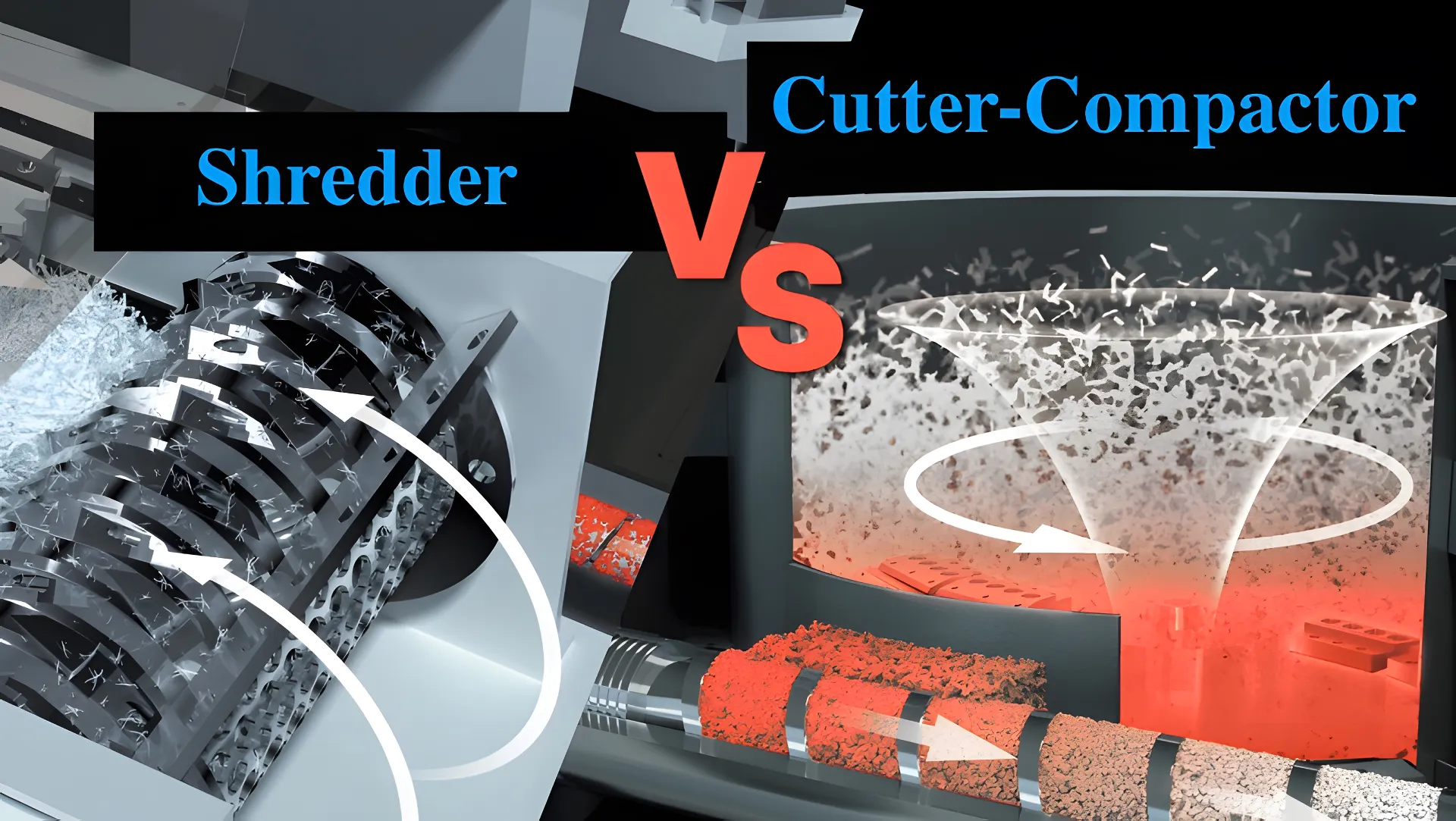

The right машина за рециклажу пластике is crucial for improving operational efficiency. Both cutter-compactors and shredders can effectively reduce the size of plastic waste, but they work in different ways. This article will help you determine which machine is best suited for your recycling needs.

Understanding Cutter-Compactors and Shredders in Plastic Recycling

When selecting equipment for plastic recycling, it's important to understand the differences between cutter-compactors and shredders. These two machines play distinct roles in preparing plastic waste for extrusion and пелетизирање. This article explores the key differences in their functions, applications, and material suitability.

How Does Customization Maximize Efficiency in Plastic Recycling?

Customizing plastic recycling machines is crucial for enhancing the efficiency of recycling operations. Here's how customization can transform your recycling process:

Today, plastic products come in various shapes, sizes, layers, print levels, and formulations, making the recycling process challenging. Selecting the right plastic recycling line, feeding system, degassing system, filtration device, and pelletizing system can significantly improve recycling efficiency. Therefore, the first step in choosing recycling equipment is to accurately identify the type of plastic waste.

Plastic recycling is a critical part of reducing waste and conserving resources. However, not all plastic waste is created equal. Two primary types of plastic recycling are Post-Industrial и Post-Consumer. While both aim to recycle plastic and reduce landfill waste, they operate under different conditions and processes. In this article, we’ll explore the distinctions between these two recycling methods and their unique advantages.