У свету индустријске рециклаже који се стално мења, разумевање основних принципа рада машина је кључно за избор праве опреме за ваше пословање. Један такав комад опреме је Машина за хладно пресовање ЕПС-а – витални алат за ефикасну рециклажу експандиране полистиренске (ЕПС) пене. ЕПС се широко користи у паковању и грађевинарству, али његово одлагање представља значајне еколошке изазове због своје мале тежине и гломазности. Машина за хладно пресовање ЕПС-а пружа одрживо решење сабијањем и рециклирањем овог материјала у облик који је лакше управљати.

Овај чланак нуди детаљно објашњење како машина за хладно пресовање EPS-а функционише, истражујући њене карактеристике, примене и предности које нуди индустријским операцијама рециклаже.

Шта је машина за хладно пресовање EPS-а?

Један Машина за хладно пресовање ЕПС-а је машина за рециклажу посебно дизајнирана за компресију и рециклажу отпада од ЕПС пене. Користи механички процес пресовања који ради без потребе за топлотом, што га чини енергетски ефикаснијим и еколошки прихватљивијим у поређењу са другим методама. Процес помаже у смањењу запремине отпада од ЕПС пене, претварајући га у компактан облик који се може поново користити у производњи или даље прерадити у друге производе.

Кључне карактеристике:

- Технологија хладног пресовања: Користи притисак уместо топлоте за компресију ЕПС пене.

- Енергетски ефикасно: Троши мање енергије у поређењу са термичким методама.

- Компактан и робустан: Ефикасно рукује великим количинама отпада од ЕПС-а.

За више информација о томе како ове машине могу поједноставити ваш процес рециклаже EPS-а, посетите нашу Машина за хладно пресовање ЕПС пене страница.

Принцип рада ЕПС машине за хладно пресовање

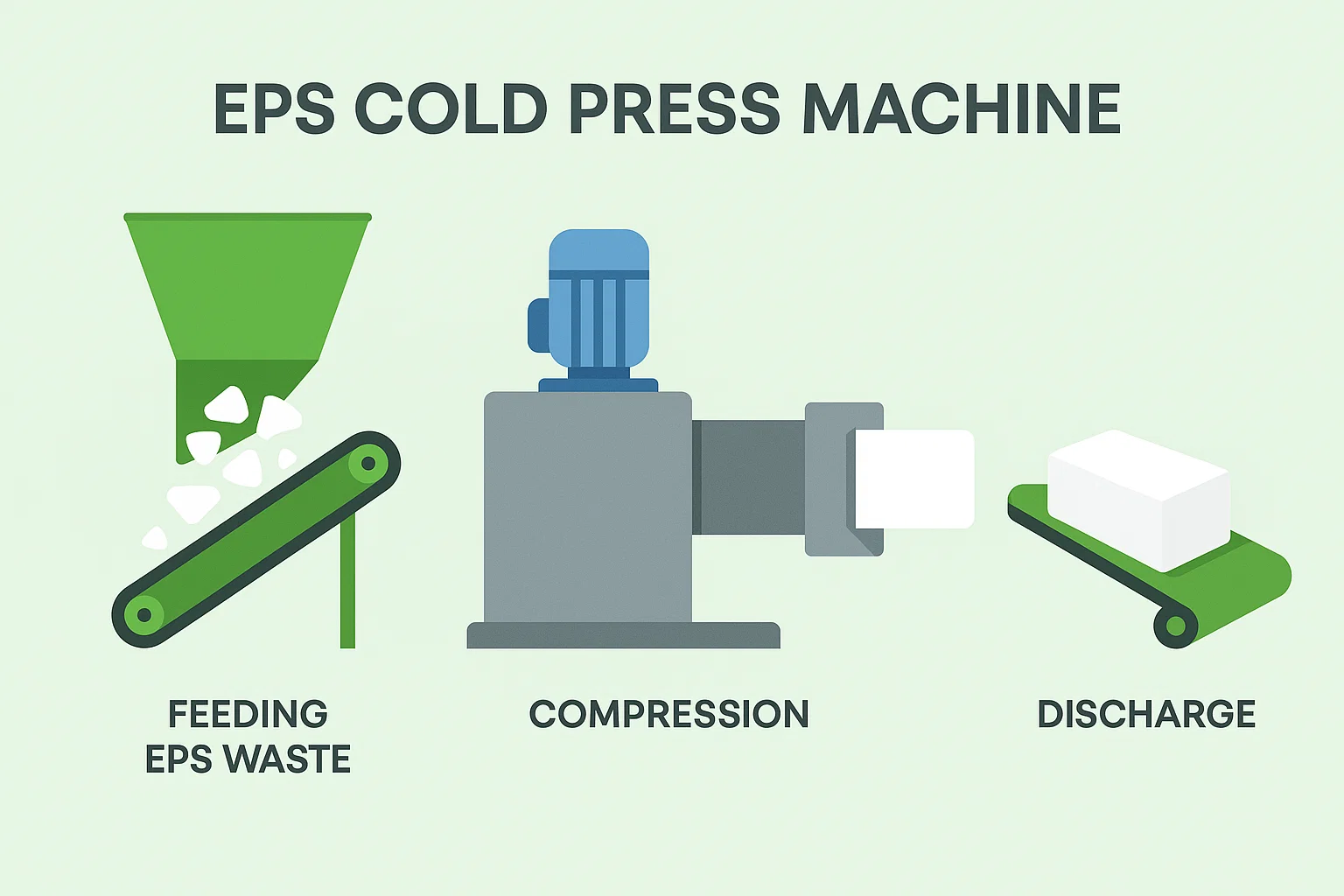

Принцип рада машине за хладно пресовање EPS-а је утемељен у њеном једноставном, али ефикасном раду. Хајде да га поделимо на кључне фазе како бисмо јасније разумели процес:

1. Убацивање отпада од ЕПС пене

Процес почиње убацивањем отпада од ЕПС пене у машину. То може да укључује широк спектар ЕПС производа, као што су материјал за паковање, изолација и грађевински отпад. Пена се обично разбија на мање комаде или грудве како би стала у левак машине.

2. Процес компресије

Када се пена убаци у левак, она се премешта у комору за пресовање, где се одвија главна акција. ЕПС пена се излаже високом притиску помоћу механичког система пресовања. Током ове фазе, пена се сабија, а ваздух унутар материјала се истискује, значајно смањујући његову запремину.

Хидраулични систем машине осигурава да је примењени притисак конзистентан и може се подесити у зависности од специфичних захтева врсте и запремине пене.

3. Обликовање и формирање

Након компресије, ЕПС материјал се често обликује у компактне блокове или бале. Ови блокови су лакши за руковање, складиштење и транспорт, што их чини много ефикаснијим за рециклажу и поновну употребу. Компактовани блокови такође имају смањену површину, што их чини еколошки прихватљивијим када се одлажу или даље обрађују.

4. Отпуст

Када се ЕПС пена сабије у блокове или бале, она се испушта из машине. Ови компримовани облици ЕПС-а су затим спремни за даљу обраду, као што је употреба у производњи нових производа или слање на напредније технике рециклаже.

Предности коришћења ЕПС машина за хладно пресовање

The Машина за хладно пресовање ЕПС-а нуди низ предности, што га чини вредним алатом за индустрије које желе ефикасно да управљају отпадом од EPS-а:

- Утицај на животну средину: Рециклирањем EPS пене, машина помаже у смањењу отпада који често завршава на депонијама. Процес хладног пресовања је такође еколошки прихватљивији, трошећи мање енергије него термичке методе.

- Исплативо: Отпад од EPS-а може се брзо акумулирати у индустријама као што су паковање и грађевинарство. Компресовањем пене, предузећа могу смањити простор потребан за складиштење, што доводи до уштеде трошкова у управљању отпадом.

- Побољшана ефикасност рециклаже: ЕПС пена, када се сабије, може се лакше обрадити и поново употребити у производњи, затварајући круг отпада и подстичући одрживост.

- Минимално одржавање: Процес хладног пресовања смањује хабање машина у поређењу са методама заснованим на топлоти, што доводи до нижих трошкова одржавања.

Примене машина за хладно пресовање ЕПС-а

Машине за хладно пресовање EPS-а су веома свестране и могу се користити у разним индустријама које се баве великим количинама EPS отпада. Неке од главних примена укључују:

- Индустрија паковања: ЕПС се често користи у материјалима за паковање, посебно за крхку робу. Машина за хладно пресовање помаже у компресовању одбачених материјала за паковање ради лакше рециклаже.

- Грађевинска индустрија: ЕПС се користи као изолациони материјал у грађевинском сектору. Машина за хладно пресовање омогућава ефикасну рециклажу отпадног изолационог материјала.

- Електроника: Многи електронски производи су упаковани у EPS пену како би се спречила оштећења током транспорта. Рециклирање ове пене машином за хладно пресовање смањује отпад и промовише циркуларност у ланцу снабдевања.

Кључна разматрања при избору машине за хладно пресовање EPS-а

Приликом куповине машине за хладно пресовање EPS-а за ваше пословање, треба узети у обзир неколико фактора како бисте били сигурни да ћете изабрати прави модел за своје потребе:

- Капацитет машине: Уверите се да машина може да обради количину отпада од ЕПС-а који ваш објекат генерише.

- Потрошња енергије: Одаберите машине које нуде високу ефикасност и ниску потрошњу енергије како бисте смањили оперативне трошкове.

- Издржљивост и одржавање: Потражите робусне машине које захтевају минимално одржавање и направљене су да трају у тешким условима рада.

- Једноставност рада: Изаберите машину са једноставним контролама и минималном оперативном сложеношћу како бисте повећали продуктивност.

Закључак

The Машина за хладно пресовање ЕПС-а је вредна предност у индустријском сектору рециклаже, нудећи ефикасно и еколошки прихватљиво решење за отпад од ЕПС пене. Разумевањем његовог принципа рада, карактеристика и предности, можете донети информисану одлуку при избору машина за рециклажу за ваше пословање.

Energycle пружа висок квалитет Машине за хладно пресовање EPS-а, дизајнирана да поједностави ваше процесе рециклаже, а истовремено нуди одличне перформансе и енергетску ефикасност. Ако желите да смањите отпад, побољшате одрживост и уштедите на оперативним трошковима, ова машина би могла бити савршен избор за ваше пословање.

За више информација о нашим машинама за хладно пресовање EPS-а, посетите Машина за хладно пресовање ЕПС пене Енерџикле.