Вести о рециклажи

Textile waste is a growing concern worldwide, with millions of tons of discarded clothing, fabrics, and carpets piling up in landfills each year. As sustainability becomes a priority for businesses and consumers alike, textile shredders have emerged as a powerful tool for recycling and repurposing textile waste. But what exactly is a textile shredder, and how does it transform old fabrics into valuable resources? In this article, we’ll explore the ins and outs of textile shredders, their working mechanisms, applications, and why they’re essential for a circular economy.

Running a recycling center or waste processing plant is no small feat. You’re juggling throughput, costs, and sustainability goals, all while ensuring your equipment can handle the daily grind. A single-shaft shredder is a cornerstone for turning plastic waste into something reusable, but picking the right one can feel like navigating a maze. Don’t worry—this guide is here to help you find the perfect shredder for your operation, with practical tips to cut through the noise and make a choice that boosts efficiency and saves you headaches.

А wet crusher & granulator is an essential piece of equipment designed specifically for plastic recycling operations. By simultaneously crushing plastic waste into smaller particles and cleaning it with water, it significantly enhances recycling efficiency and produces higher-quality granules suitable for reuse.

Поливинилхлорид (ПВЦ) је свестран и широко коришћен полимер у индустријама, од грађевинарства до паковања. Међутим, прерада ПВЦ-а у фине прахове за примене попут премаза, цеви или фитинга захтева дробилице—специјализоване машине које мељу ПВЦ у једноличне честице. Ефикасност и перформансе ових пулверизатора у великој мери зависе од ПВЦ формулације која се обрађује. Варијације у адитивима, као што су пластификатори, стабилизатори и пунила, могу значајно утицати на перформансе пулверизатора, утичући на проток, потрошњу енергије и квалитет производа. У овом чланку ћемо истражити како различите ПВЦ формулације утичу на перформансе пулверизатора и пружити практичне стратегије за оптимизацију резултата обраде.

In today’s fast-evolving recycling industry, businesses need dependable equipment that delivers top performance while supporting sustainability goals. The Energycle PP PE film washing line is a premier solution for processing polypropylene (PP) and polyethylene (PE) films—common materials in packaging, agriculture, and industrial applications. With its exceptional quality, innovative design, and unmatched service, Енерџикл stands out as the go-to choice for plastic film recycling. In this article, we’ll dive into why this washing line is the ideal investment, offering practical insights into its efficiency, technology, and long-term benefits.

Пластични гранулатор је у сржи рециклаже и производње, трансформишући гломазан пластични отпад у управљив, поново употребљив рециклирани материјал. Али у сржи овог суштинског процеса је кључна компонента која се често потцењује: секач за пластични гранулатор. Избор неодговарајућег секача може довести до смањене ефикасности, лошег квалитета рециклираног материјала, веће потрошње енергије, честих застоја и повећаних оперативних трошкова.

Polyethylene (PE) film is ubiquitous – from packaging wraps to agricultural films. Recycling this valuable resource is crucial for sustainability, and at the heart of this process lies the PE film washing line. This sophisticated equipment transforms dirty, post-consumer or post-industrial film into clean flakes ready for pelletizing and reuse. However, like any industrial machinery, optimal performance hinges on consistent and thorough maintenance and care.

In the world of plastics processing and recycling, the пластични гранулатор is a cornerstone piece of equipment. Whether you're dealing with production scrap, rejected parts, or post-consumer waste, efficiently reducing plastic size is crucial for reuse, reprocessing, or disposal. However, not all granulators are created equal. Selecting the wrong machine can lead to inefficiency, poor regrind quality, excessive downtime, and ultimately, a lower return on investment (ROI).

The sheer volume of textile waste generated globally presents a significant challenge, but within this challenge lies a powerful opportunity for innovation and sustainability. Efficiently breaking down fabric materials into smaller components is a crucial step in both recycling and responsible waste management, paving the way for repurposing and minimizing environmental impact. Енерџикл stands at the forefront of this effort, offering advanced textile shredders specifically engineered to tackle the complexities of fabric processing and contribute to a more circular economy.

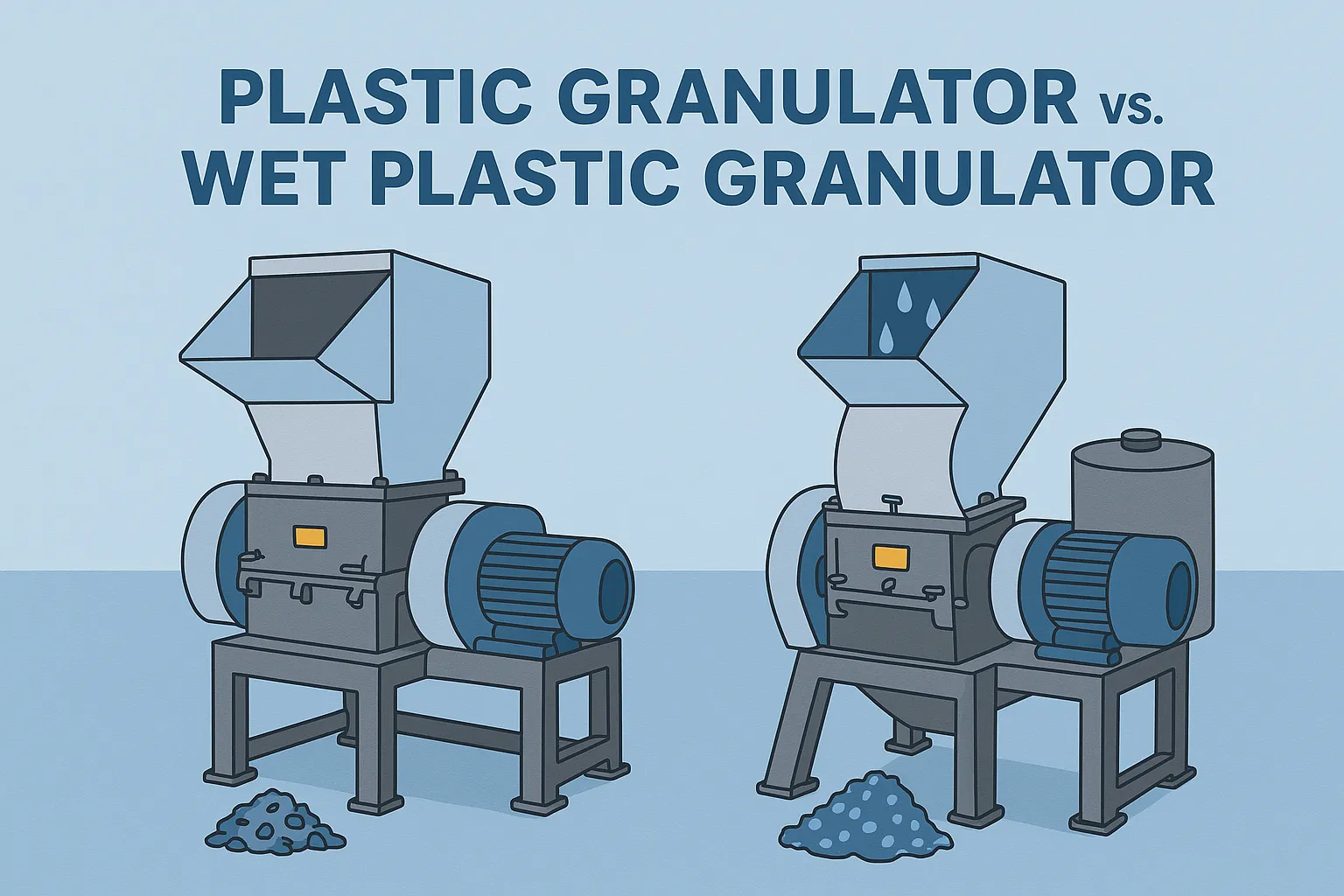

У динамичном свету рециклаже пластике, ефикасност и ефективност су од највеће важности. Кључни корак у овом процесу укључује смањење пластичног отпада на комаде којима се може управљати, и ту долазе до изражаја пластични гранулатори. Док су стандардни пластични гранулатори били главни алат у индустрији, влажни пластични гранулатори су се појавили као убедљива алтернатива. Ово свеобухватно поређење бави се сличностима и кључним разликама између ове две технологије, истражујући њихове предности и мане како би вам помогло да донесете информисану одлуку за ваше операције рециклаже.