Вести о рециклажи

This guide provides a detailed exploration of selecting the appropriate Линија за прање ПЕТ флаша for your recycling business, ensuring efficiency, quality, and cost-effectiveness. PET bottle washing lines are critical for transforming used polyethylene terephthalate (PET) bottles into clean PET flakes, which are then repurposed for various applications such as new bottles, textiles, and packaging materials. The process involves several stages, including debaling, sorting, washing, and drying, and the choice of line can significantly impact your operation’s success.

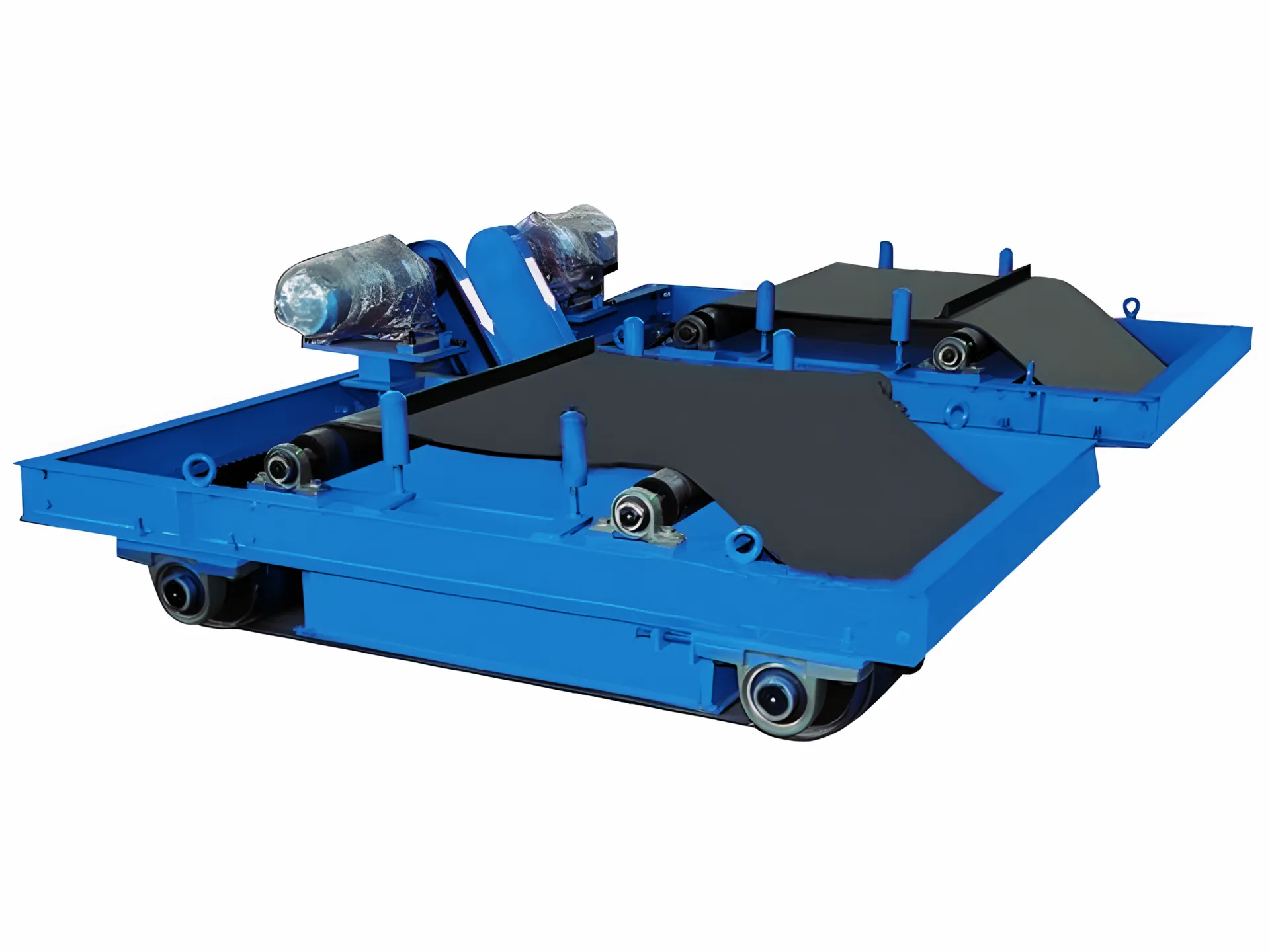

Suspended Self-Discharging Magnetic Separators are specialized industrial equipment designed to remove ferrous metals from conveyor belts. They are suspended above the conveyor and feature an automated self-cleaning mechanism, such as a continuously moving belt, to discharge captured metal into a collection bin or chute. This automation ensures uninterrupted operation, making them ideal for high-volume industrial processes.

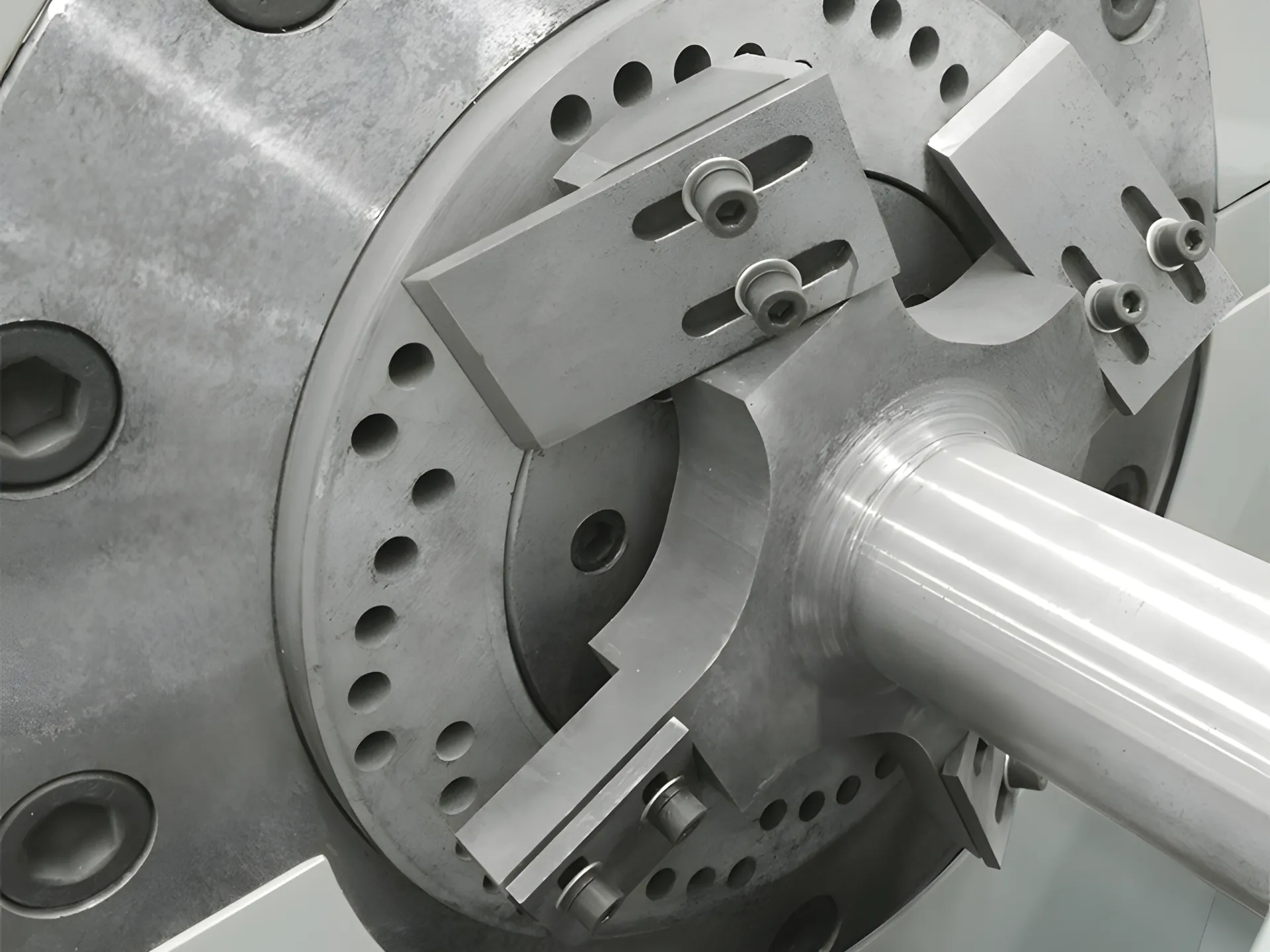

Plastic pelletizing machines play a crucial role in converting plastic waste or raw materials into small granules, which are widely used in manufacturing injection-molded products, films, and sheets. Among the core processes of pelletizing, the cutting method directly influences the uniformity and quality of the granules. Based on existing research, the “cutting method” primarily consists of three techniques: gantry cutting, horizontal water ring cutting, and underwater cutting. These methods encompass both cold-cut and hot-cut techniques.

PET (Polyethylene Terephthalate) washing lines are systems used to clean and recycle PET bottles into flakes for reuse, such as in new bottles or fibers. The main difference between cold and hot washing lines is the water temperature used, which affects cleaning effectiveness, energy use, and the quality of the final product.

In the recycling and environmental protection industry, the single-layer сепаратор вртложних струја has become one of the core devices for industrial waste processing due to its highly efficient and precise metal sorting capabilities. This article provides an in-depth analysis of its working principles, technical advantages, and application scenarios, helping you gain a comprehensive understanding of this “metal sorting powerhouse.”

In the world of PET recycling, PVC (polyvinyl chloride) is a dreaded contaminant. Even in trace amounts, PVC can wreak havoc during the processing and remanufacturing of post-consumer PET resin, leading to significant quality issues in the final product. For context, PVC contamination as low as 50 parts per million (ppm)—equivalent to just 0.05 kg of PVC in 1,000 kg of PET flakes—can cause severe problems. This minuscule concentration (0.005%) can lead to the breakdown of PET resin, resulting in brittleness, discoloration (yellowing), and the release of hazardous chlorine vapors. These issues undermine two of PET's most valued properties: clarity и impact strength.

Selecting the ideal plastic granulator is a critical investment that can significantly impact your operation's efficiency and profitability. Energycle's пластични гранулатори комбинују прецизно инжењерство са издржљивошћу како би се носили са захтевним применама рециклаже. Овај свеобухватни водич ће вам помоћи да идентификујете савршену машину за ваше специфичне потребе.

Plastic film recycling is an essential aspect of modern waste management, addressing the growing challenge of managing lightweight, flexible plastic waste. This survey note provides an in-depth exploration of film recycler machines, their features, benefits, and operational mechanisms, drawing on extensive research to ensure a thorough understanding for both industry professionals and lay readers.

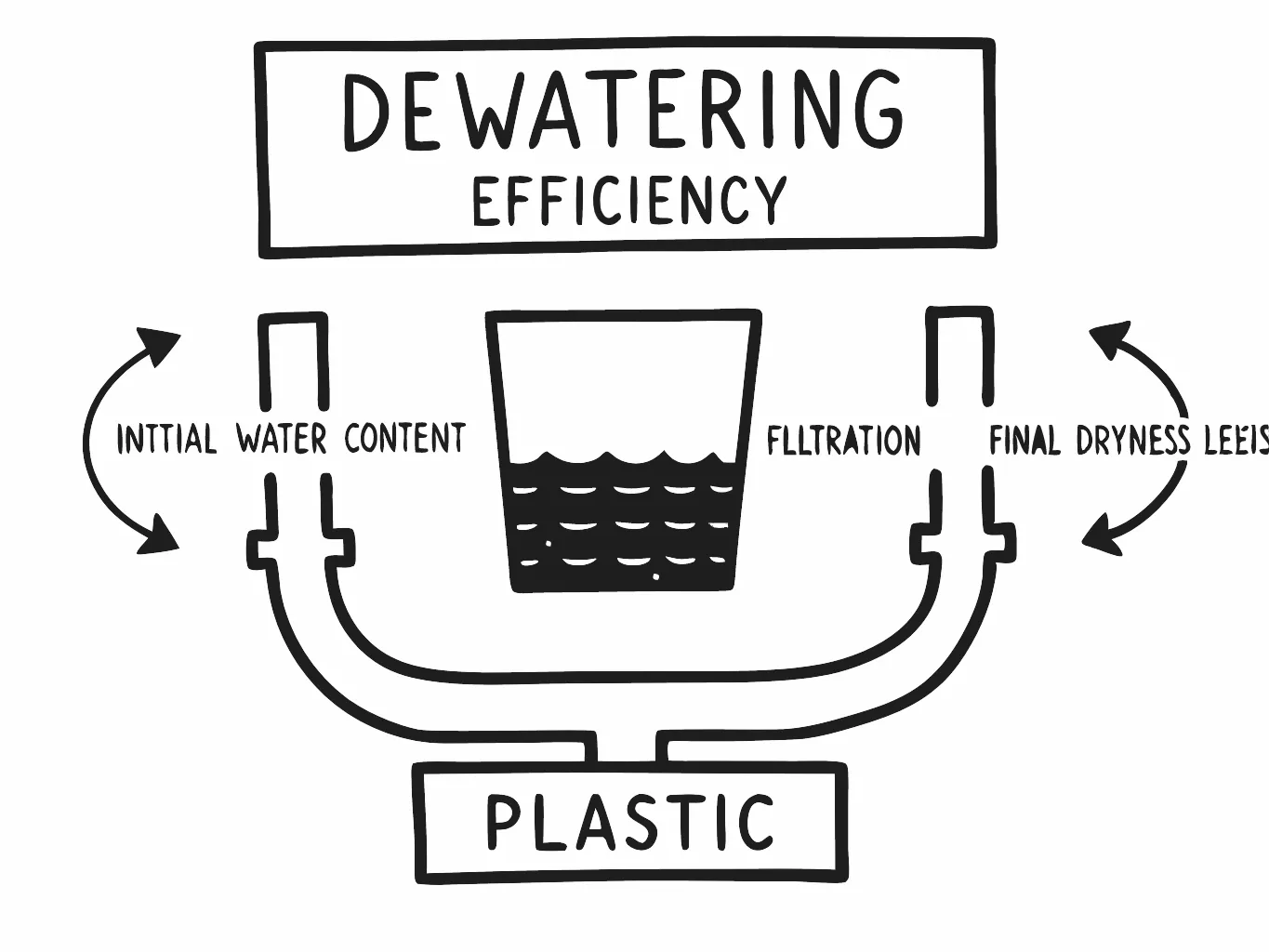

When it comes to maximizing dewatering efficiency for plastic films—think polyethylene (PE) or polypropylene (PP)—the equipment you choose can make or break your recycling operation. These machines aren’t just tools; they’re investments in quality output, cost savings, and sustainability. Let’s break down the standout features, benefits, and qualities of mechanical dewatering equipment, focusing on what matters most to businesses in this space.

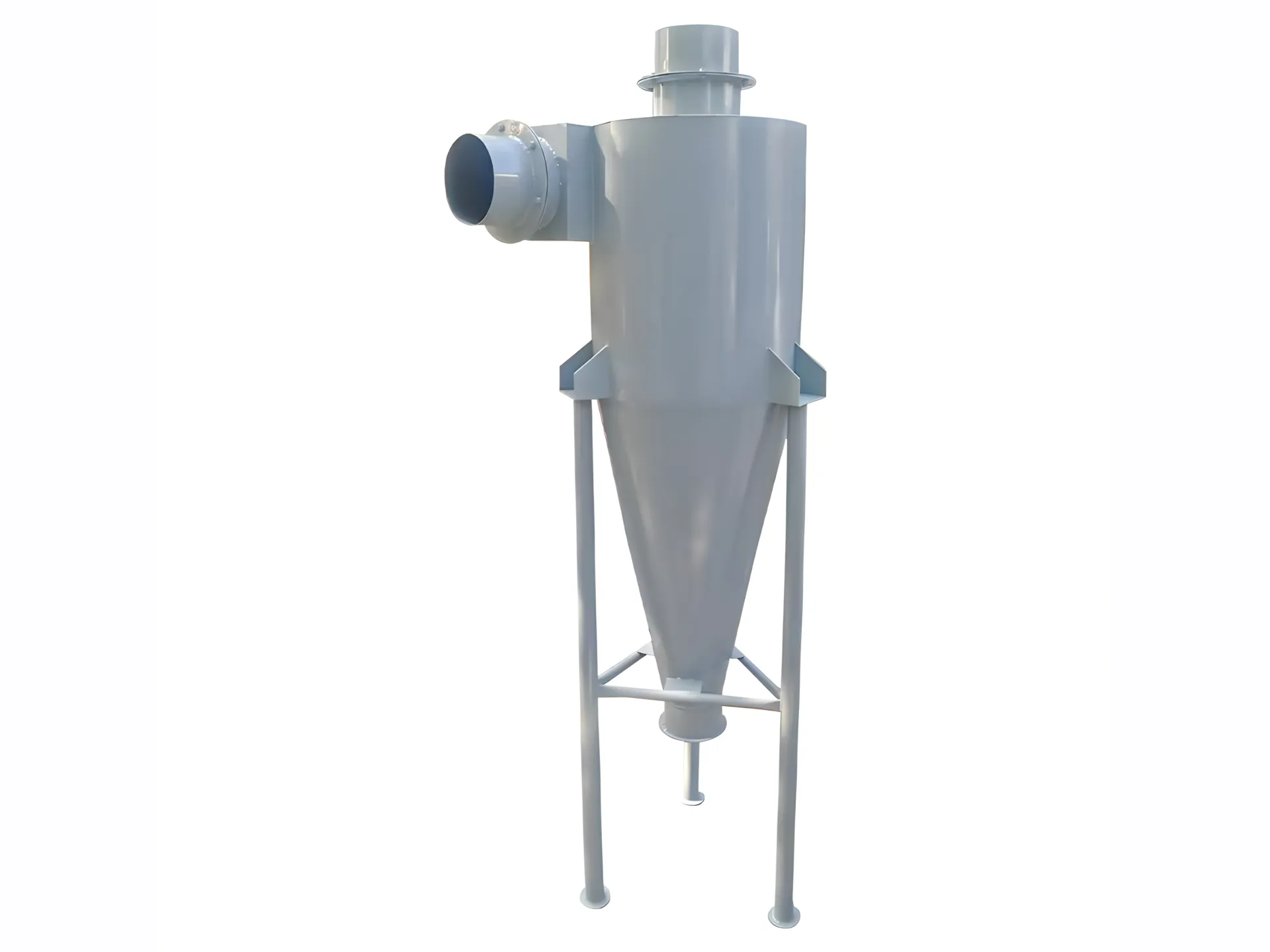

Cyclone Separators in Plastic Recycling: Key Mechanisms & Applications

Cyclone separators are critical in plastic recycling for efficiently sorting and purifying materials by leveraging differences in particle density, size, and airflow dynamics. Here’s how they are tailored to meet industry-specific needs:

Tire recycling is an essential process in managing the increasing volume of discarded tires. A critical step in this process involves cutting the sidewall of the tire. Understanding the rationale behind this step highlights its significance in the recycling chain and its impact on material recovery and equipment efficiency.

For small businesses, selecting the right plastic recycling equipment requires balancing cost, efficiency, and long-term operational needs. Here are practical suggestions from the perspectives of core functions, applicable scenarios, and cost-effectiveness.