Recycling post-consumer plastics like PE film, PP woven bags, and agricultural films can be a challenge due to high moisture content. Washed films typically contain up to 40% moisture, which is problematic for recyclers, leading to issues like inconsistent feeding and reduced output in recycling extruders. Traditional drying methods often fail to effectively remove this moisture, leaving up to 30% water content in the materials.

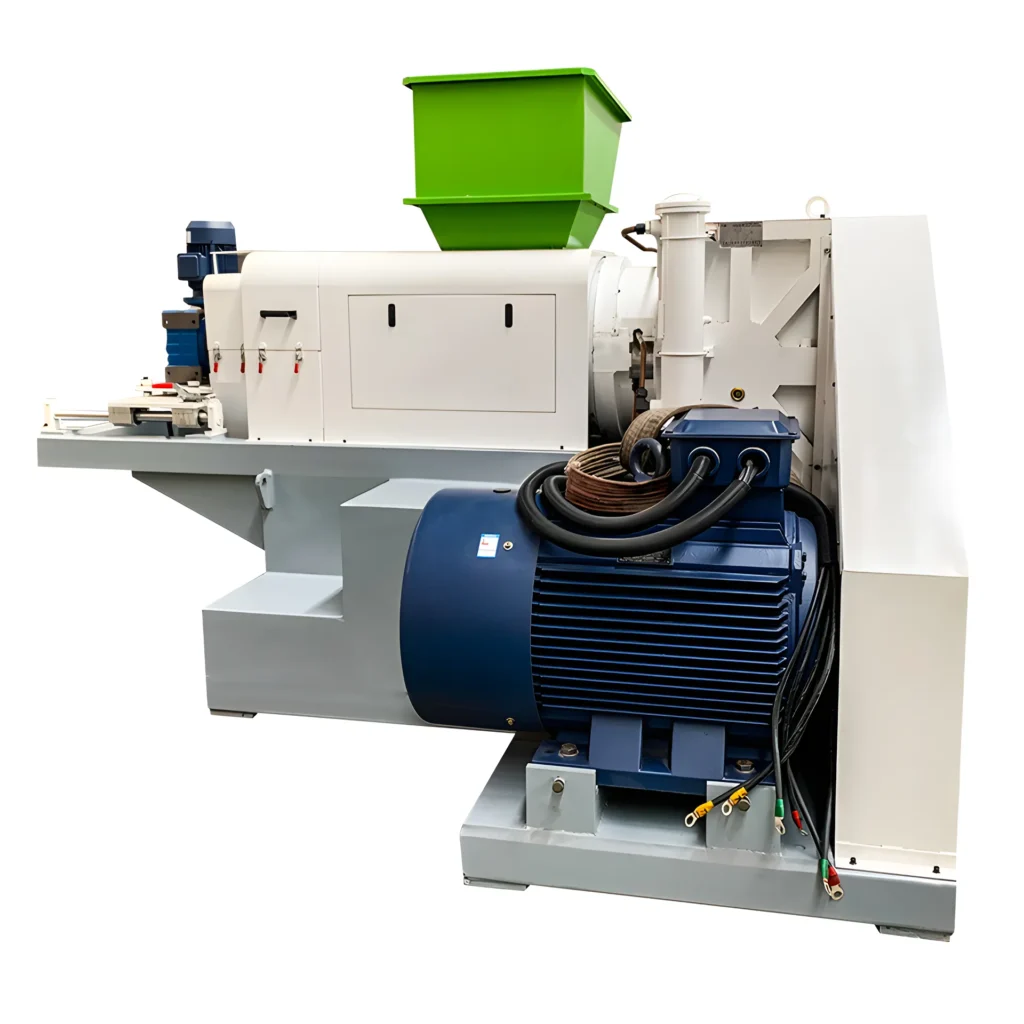

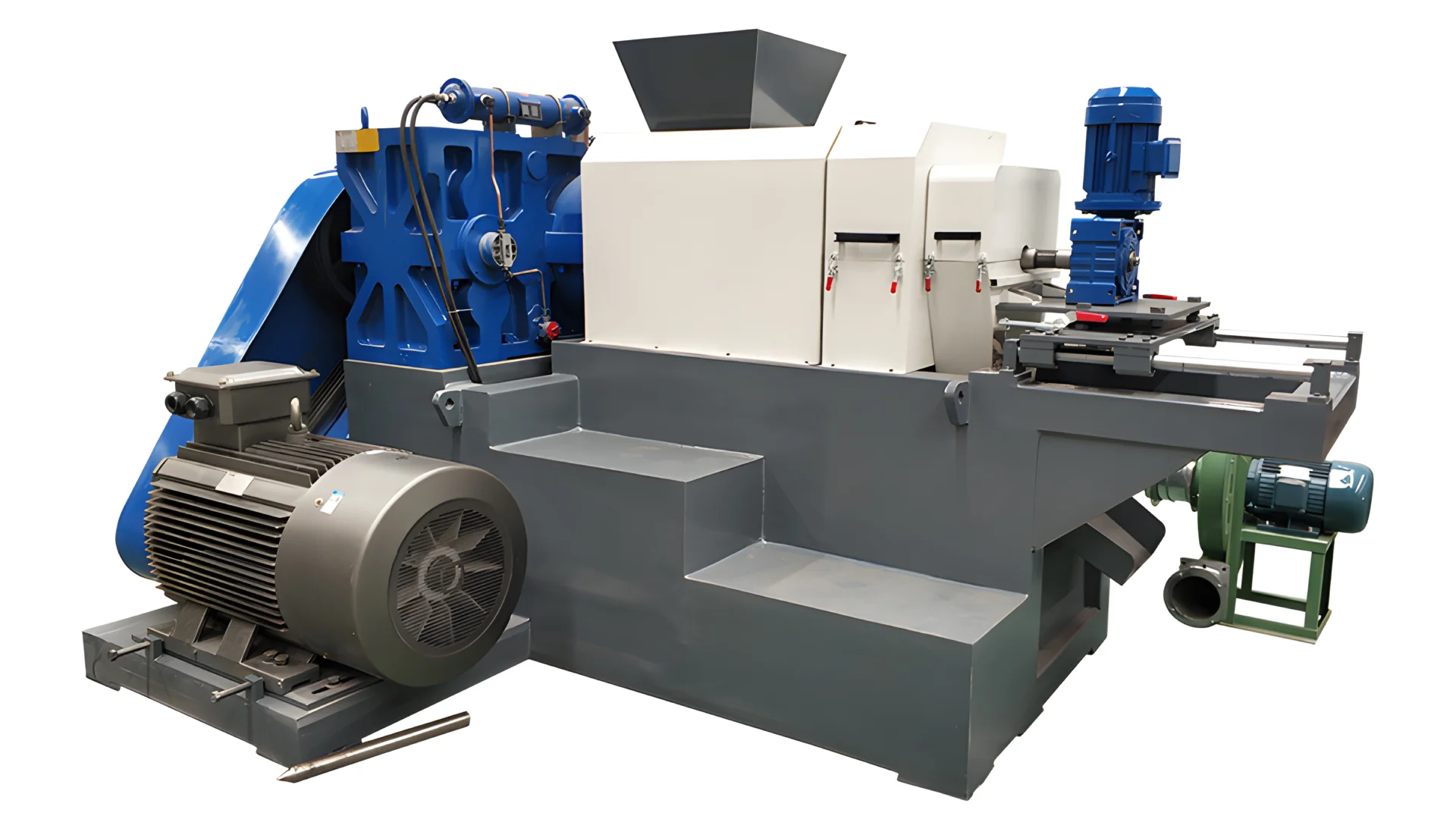

This is where a Plastic Film Squeezer Drying Machine comes in. This advanced drying solution is specifically designed to address the shortcomings of conventional drying methods, providing a more efficient and effective way to prepare plastic film flakes for recycling.

Main Function of the Plastic Film Squeezer Drying Machine

The Plastic Film Squeezer Dryer is engineered to handle pre-washed materials such as post-consumer PE films, PP woven bags, PP jumbo bags, and agricultural films. After these materials are washed, they enter the squeezer dryer in the form of flakes, where the machine effectively reduces the water moisture level from 10-35% down to an impressive 1-5%.

Caracteristici cheie:

-

- Moisture Reduction: Lowers water moisture from up to 35% down to as low as 1%, making it one of the most effective drying solutions available.

- Compaction of Film Flakes: Transforms lightweight film flakes into denser solid lumps, resulting in higher density and reduced volume.

- Faster Drying Process: Provides quicker drying compared to centrifugal or hot air drying methods.

- Low Heat Generation: Ensures minimal heat exposure, reducing the risk of material degradation and maintaining the quality of the recycled pellets.

- Extrusion Preparation: Optimally prepares materials for the subsequent extrusion-pelletizing process.

Specification:

| Model | Screw Diameter | Screw Barrel Material & Treatment | Putere motor | Heating Power | Capacitate |

|---|---|---|---|---|---|

| ERCJG250 | 250mm | 38CrMoAlA Nitride | 90kw | 15kw | 200-300kg/h |

| ERCG300 | 300mm | 38CrMoAlA Nitride | 110-132kw | 22kw | 300-400kg/h |

| ERCG320 | 320mm | 38CrMoAlA Nitride | 160-185kw | 30kw | 500-600kg/h |

| ERCG350 | 350mm | 38CrMoAlA Nitride | 200-220kw | 36kw | 700-800kg/h |

Benefits of Using a Plastic Film Squeezer Dryer

The benefits of using a Plastic Film Squeezer Dryer are substantial for recyclers aiming to improve efficiency and output quality.

1. Increase Extruder Efficiency

- Enhanced Output Capacity: The drying machine increases the efficiency of the pelletizing extruder and the overall recycling process by ensuring that the input material is consistent and well-prepared.

- Stable Feeding: Due to the compaction of film flakes into solid lumps, feeding into the extruder becomes smoother and more stable, reducing downtime and enhancing productivity.

2. Improve Pellet Quality

- Consistent Material Input: By significantly reducing moisture content and increasing material density, the machine ensures a steady and consistent feed to the pelletizing extruder.

- Superior End Product: With more uniform feeding, the quality of recycled pellets is improved, resulting in higher market value and greater usability.

3. Integration with Recycling Extruder and Washing Line

The Plastic Film Squeezer Dryer is specially designed to work in tandem with the recycling line’s washing and extrusion-pelletizing components, maximizing output and efficiency.

Seamless Workflow:

- Washing Line: The plastic film is cleaned to remove contaminants.

- Plastic Squeezer Dryer: The washed material is dried and compacted, reducing moisture to a minimal level.

- Plastic Recycling Extruder: The dry, dense material is fed into the extruder, where it is melted and formed into pellets.

By integrating these processes, the machine ensures that the output from the recycling line is maximized, providing a cost-effective and environmentally friendly solution for post-consumer plastic recycling.

Imagini suplimentare

Concluzie

In the world of plastic recycling, moisture content is a significant hurdle that impacts efficiency, output, and quality. The Plastic Film Squeezer Drying Machine is an innovative solution that directly addresses these challenges, providing a faster, more efficient, and environmentally friendly drying method. By reducing moisture to minimal levels and compacting materials for easier feeding, it enhances both the productivity and quality of recycled products. This makes it an essential piece of equipment for any modern recycling operation.

Garanție și instalare

Fiecare mașină de reciclare include o garanție limitată de 1 an. Oferim servicii de instalare, inginerii noștri vizitând locația dumneavoastră pentru a vă ajuta în procesul de configurare. De asemenea, se pot face aranjamente pentru echipe de întreținere regulată și consultanți operaționali.

Întreabă acum

Pentru a primi cele mai recente prețuri și termene de livrare, trimiteți-ne un mesaj folosind formularul de mai jos.

[…] Squeezing Technology: Enhanced Dewatering with Mechanical […]