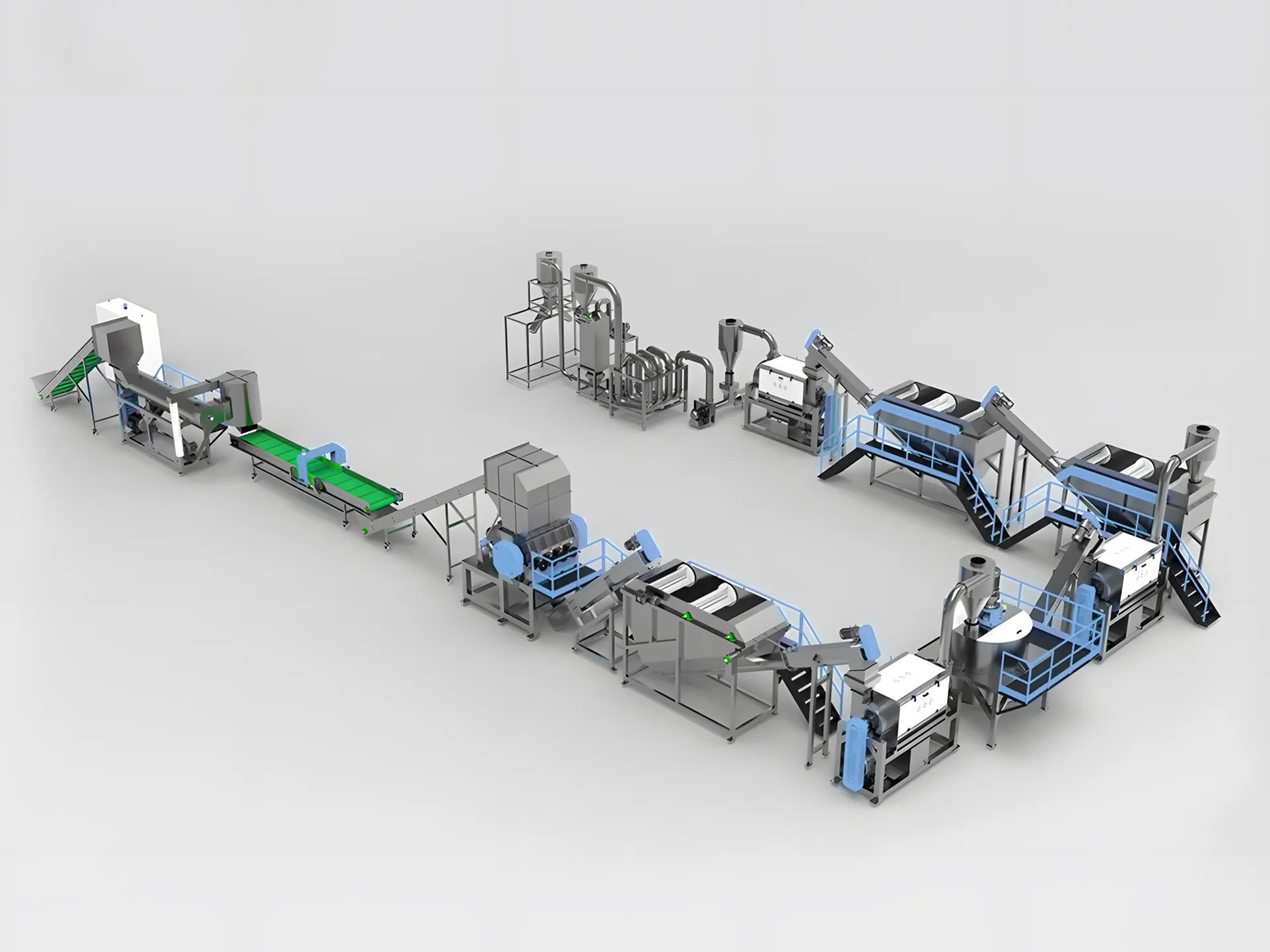

Процес рециклаже ПЕТ боца: од бале до пахуљице

Наш систем за прање ПЕТ боца је пројектован да трансформише ваш процес рециклаже са неупоредивом ефикасношћу и поузданошћу. Користећи најсавременију технологију чишћења, он пажљиво уклања загађиваче, етикете и друге нечистоће са ПЕТ боца, обезбеђујући изузетно висок квалитет производа. Поред својих изванредних перформанси, систем је дизајниран имајући у виду уштеду енергије, смањујући оперативне трошкове уз одржавање врхунске ефикасности. Његов еколошки прихватљив дизајн минимизира потрошњу воде и садржи биоразградива средства за чишћење, што га чини идеалним избором за предузећа посвећена одрживости и смањењу свог еколошког отиска. Изаберите наш систем да бисте унапредили своје операције рециклаже и допринели чистијој, зеленијој будућности.

Ефикасан механизам за дробљење

Машина за рециклажу ПЕТ флаша брзо дроби флаше на мале комадиће, повећавајући ефикасност рециклаже и припремајући материјале за прераду.

Напредна технологија сортирања

Опремљен напредним сортирањем, прецизно одваја пластику и загађиваче, обезбеђујући висококвалитетне и чисте рециклиране материјале.

Једноставан интерфејс

Интуитивни интерфејс омогућава корисницима да лако надгледају, подешавају подешавања, прате перформансе и решавају проблеме са лакоћом.

Компактан дизајн

Његов компактни дизајн одговара малим објектима и урбаним просторима, штедећи простор и омогућавајући једноставну инсталацију и рад без великог простора.

Издржљивост и лако одржавање

Направљен од издржљивих материјала, издржава континуирану употребу, захтева минимално одржавање и смањује време застоја и оперативне трошкове.

Енергетска ефикасност

Дизајниран са технологијом за уштеду енергије, смањује потрошњу енергије, снижава трошкове и подржава одрживе праксе рециклаже.

Кључне компоненте нашег система за рециклажу ПЕТ материјала

Аутоматски разбијач бала (Debaler)

Разбијач бала, или Дебалер, је пројектован да поуздано отвара и одваја компримоване бале, обезбеђујући доследан и ефикасан почетак целог процеса рециклаже.

Функција

Након што се жице за бале уклоне, комплетна, збијена бала се утоварује на транспортер. Ротационе осовине машине са високим обртним моментом агресивно раздвајају балу, ослобађајући боце у слободан ток за равномерно довод у линију за прање.

Техничке карактеристике

- Тешка конструкција: Направљен са робусним челичним оквиром и компонентама отпорним на хабање како би се носио са огромним притиском збијених бала 24/7.

- Мотори са високим обртним моментом: Опремљен снажним моторима и мењачима који обезбеђују потребну силу за ломљење чак и најгушће збијених бала.

- Подесива контрола брзине: Омогућава оптимизацију брзине пуњења како би се савршено ускладила са капацитетом остатка линије за прање.

Тромелов екран

Тромел сито је критична јединица за претходно чишћење дизајнирана да одвоји ПЕТ боце од мањих, тешких загађивача, штитећи низводну опрему и побољшавајући укупну ефикасност линије.

Функција

Како боце улазе у споро ротирајући, нагнути бубањ, оне се нежно котрљају. Сито је перфорирано рупама мањим од боца. Ова радња омогућава да мали, тврди загађивачи попут разбијеног стакла, камења, металних комада, песка и прљавштине пропадну и буду одвојено сакупљени, док се нетакнуте боце транспортују даље у следећу фазу.

Техничке карактеристике

- Прилагодљиве перфорације екрана: Величине отвора на ситу могу се прилагодити специфичној врсти и нивоу контаминације у вашој сировини.

- Тешка челична конструкција: Направљен са робусним оквиром и издржљивим, отпорним на хабање бубњем како би издржао континуирани рад са абразивним материјалима.

- Оптимизована брзина и угао ротације: Пројектовано да максимизира ефикасност сепарације без ломљења самих ПЕТ боца.

Мокри пластични гранулатор (дробилица)

Мокри гранулатор је срце процеса смањења величине. Пројектован је да ефикасно сече целе или претходно уситњене ПЕТ боце у једноличне пахуљице, истовремено вршећи ефикасно претходно прање.

Функција

Боце се убацују у комору за сечење где се окреће ротор велике брзине са више сечива, стварајући сечење попут маказа у односу на непокретне ножеве. Ово агресивно смањује боце на конзистентну величину пахуљица, одређену перфорираним ситом на дну коморе. Током овог процеса, вода се континуирано убризгава да би се материјал хладио, подмазивао и чистио.

Техничке карактеристике

- Дизајн ротора типа V: Обезбеђује врхунско приањање материјала и високо ефикасно сечење са ниском потрошњом енергије.

- Ојачане сечива од челика D2/SKD-11: Нуди одличну отпорност на хабање и дуг век трајања пре него што је потребно оштрење или замена.

- Заменљиви екрани за подешавање величине: Омогућава лако прилагођавање коначне величине пахуљица како би се задовољили различити захтеви тржишта.

- Комора и лежајеви за тешке услове рада: Направљен да издржи тешке услове континуираног рада са великим ударцима, са спољашњим лежајевима који спречавају контаминацију водом и прљавштином.

Цик-цак ваздушни класификатор

Цик-цак ваздушни класификатор је кључна завршна јединица дизајнирана за коначно пречишћавање осушених ПЕТ пахуљица. Његова сврха је да одвоји вредне пахуљице од свих преосталих загађивача ниске густине попут папира, фолије и прашине.

Функција

Осушене пахуљице се доводе у врх машине и падају кроз вишестепени, вертикални цик-цак канал. Прецизно контролисана, навише усмерена струја ваздуха се уводи са дна. Теже ПЕТ пахуљице имају довољну масу да падну супротно од протока ваздуха и испуштају се на дну. Лакши материјали, као што су фрагменти папира и етикета, хватају се узлазном струјом, односе и сакупљају у интегрисаном циклону и систему за сакупљање прашине.

Техничке карактеристике

- Вишестепени цик-цак канал: Каскадна, цик-цак путања приморава материјал да буде више пута изложен протоку ваздуха, максимизирајући ефикасност сепарације.

- Подесива брзина ваздуха: Омогућава прецизно фино подешавање како би се постигло оптимално раздвајање за различите врсте материјала и нивое контаминације.

- Интегрисани циклон и сакупљач прашине: Обезбеђује комплетан систем затворене петље за ефикасно уклањање и сакупљање загађивача.

- Прозирни прозори за инспекцију: Омогућава лако визуелно праћење процеса раздвајања у реалном времену.

Резервоар за одвајање судопера/плутања

Резервоар за сепарацију са судопером и пловком је веома ефикасна и неопходна јединица која користи принцип густине материјала за прецизно одвајање вредних ПЕТ пахуљица од лакших полиолефинских (ПП/ПЕ) загађивача.

Функција

Мешовити ток пластичних пахуљица улази у велики резервоар напуњен водом. Споро ротирајуће лопатице нежно мешају материјал, осигуравајући да је свака пахуљица потпуно навлажена и потопљена. Због своје веће густине (>1 г/цм³), вредне ПЕТ пахуљице тону на дно. Лакши материјали попут ПП/ПЕ са чепова за боце и неких фолија за етикете (<1 г/цм³) плутају на површину. Хоризонтални пужни транспортер на дну резервоара континуирано транспортује пречишћене ПЕТ пахуљице из система, док ротирајуће лопатице на површини уклањају плутајуће загађиваче за одвојено сакупљање.

Техничке карактеристике

- Конструкција од нерђајућег челика 304: Главно тело резервоара и све компоненте у контакту са влажним материјама направљене су од нерђајућег челика отпорног на корозију за максималну издржљивост и век трајања.

- Лопатице за површинско скидање: Посебан механизам за ефикасно и аутоматско уклањање слоја плутајућих загађивача са површине воде.

- Пражњење доњег вијчаног транспортера: Обезбеђује потпуно и стабилно уклањање утонулих ПЕТ пахуљица са дна резервоара.

- Оптимизован систем циркулације и филтрације воде: Дизајниран да одржи бистрину воде и смањи укупну потрошњу воде.

Систем за прање врућом водом

Систем за топло прање је неопходна фаза за производњу висококвалитетних рециклираних ПЕТ пахуљица. Посебно је пројектован за уклањање тврдокорних, тешко чистљивих загађивача који се не могу уклонити само хладним прањем.

Функција

ПЕТ пахуљице се доводе у изоловани резервоар од нерђајућег челика где се мешају са водом загрејаном на оптималну температуру (обично 85-95°C). Прецизна количина хемијског средства (као што је каустични раствор или специјализовани детерџент) се аутоматски дозира у систем. Мешалица велике брзине затим ствара интензивно, вртложно дејство рибања. Ова моћна комбинација топлоте, хемијске реакције и рибања са високим трењем ефикасно раствара и уклања упорне лепкове, уља, масноће и остатке хране.

Техничке карактеристике

- Изоловани резервоар од нерђајућег челика 304: Направљен од нерђајућег челика отпорног на корозију за руковање хемијским агенсима и изолован за ефикасно одржавање температуре, смањујући трошкове енергије.

- Брзи фрикциони мешач: Динамички уравнотежен миксер дизајниран да створи максимално трење између пахуљица за врхунске перформансе чишћења.

- Аутоматска контрола температуре и дозирања: PLC-контролисани систем који прецизно одржава циљану температуру и управља дозирањем хемикалија за конзистентне, оптималне резултате.

- Интегрисани систем грејања: Може се конфигурисати са електричним грејним елементима или прикључцима за спољни парни котао, у зависности од инфраструктуре вашег постројења.

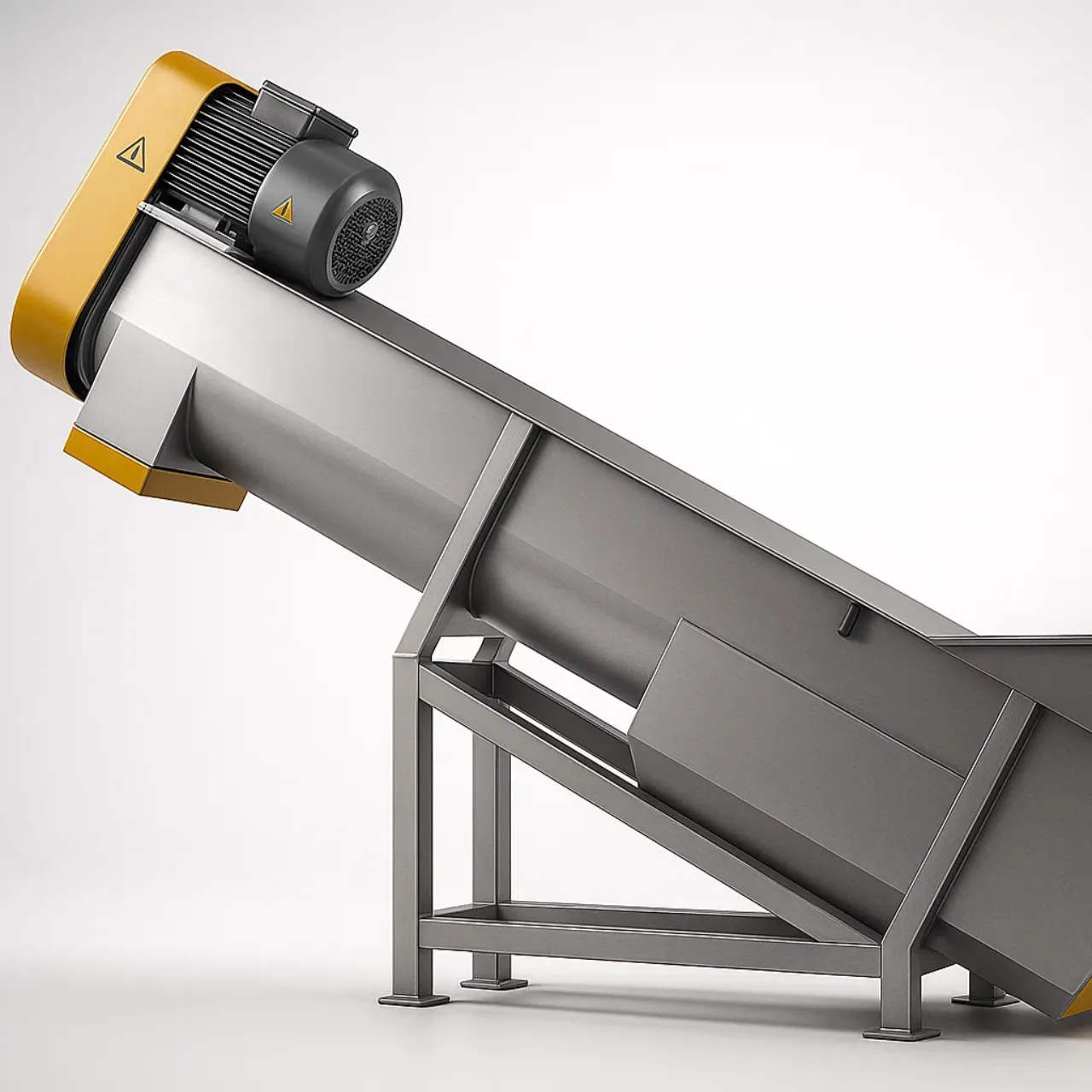

Подлошка за фрикциони вијак

Брза машина за прање фрикцијом је динамичка јединица за чишћење дизајнирана да обезбеди интензивно механичко рибање. Веома је ефикасна у уклањању тврдокорне површинске контаминације коју само испирање не може да реши.

Функција

ПЕТ пахуљице и вода се доводе у нагнуту комору за прање. Централни ротор опремљен угаоним, отпорним на хабање лопатицама окреће се великом брзином (приближно 1.000 о/мин). Ова акција ствара снажан вртлог, приморавајући ПЕТ пахуљице да интензивно трљају једне о друге, о лопатицама и околном цилиндричном мрежастом ситу. Ово трење ефикасно уклања укорењену прљавштину, блато и преосталу папирну пулпу. Прљава вода и фини загађивачи се континуирано избацују кроз сито, док се очишћене пахуљице транспортују уз нагиб и испуштају на врху.

Техничке карактеристике

- Ротор велике брзине са лопатицама отпорним на хабање: Динамички избалансиран ротор обезбеђује стабилан рад великом брзином, док очврснуте лопатице обезбеђују дуг век трајања.

- Уклоњива мрежаста заштита: Околна мрежа се може лако уклонити ради чишћења и одржавања, минимизирајући време застоја.

- Конструкција од нерђајућег челика: Све компоненте које долазе у контакт са водом направљене су од нерђајућег челика отпорног на корозију ради максималне издржљивости.

- Нагнути дизајн: Оптимизовани угао обезбеђује ефикасан транспорт материјала, чишћење и одводњавање у једној јединици.

Центрифугална машина за одводњавање

Центрифугална машина за одводњавање је високо ефикасна прва фаза процеса сушења. Њена сврха је да механички уклони велику већину воде из ПЕТ пахуљица, што драматично смањује енергију потребну за завршну фазу термичког сушења.

Функција

Влажне пахуљице из линије за прање се доводе у комору машине за одводњавање. Унутра, робустан ротор се окреће великом брзином (1.500+ о/мин), стварајући снажну центрифугалну силу. Ова сила притиска пахуљице на цилиндрично сито, истискујући воду кроз перфорације. Значајно сувље пахуљице се континуирано транспортују помоћу углованих лопатица ротора до излаза, спремне за коначно сушење.

Техничке карактеристике

- Брзи, динамички уравнотежени ротор: Пројектован за глатки рад без вибрација при великим брзинама, обезбеђујући дуг век трајања лежајева и других компоненти.

- Ротор и екран од нерђајућег челика за тешке услове рада: Ротор и сито су направљени од висококвалитетног нерђајућег челика за максималну отпорност на хабање и корозију.

- Лако приступачна сервисна врата: Дизајниран за брз и лак приступ ситу и ротору ради чишћења и одржавања, минимизирајући време застоја.

- Компактан и ефикасан дизајн: Обезбеђује високо ефикасно одводњавање на малом простору, лако се интегришући у производну линију.

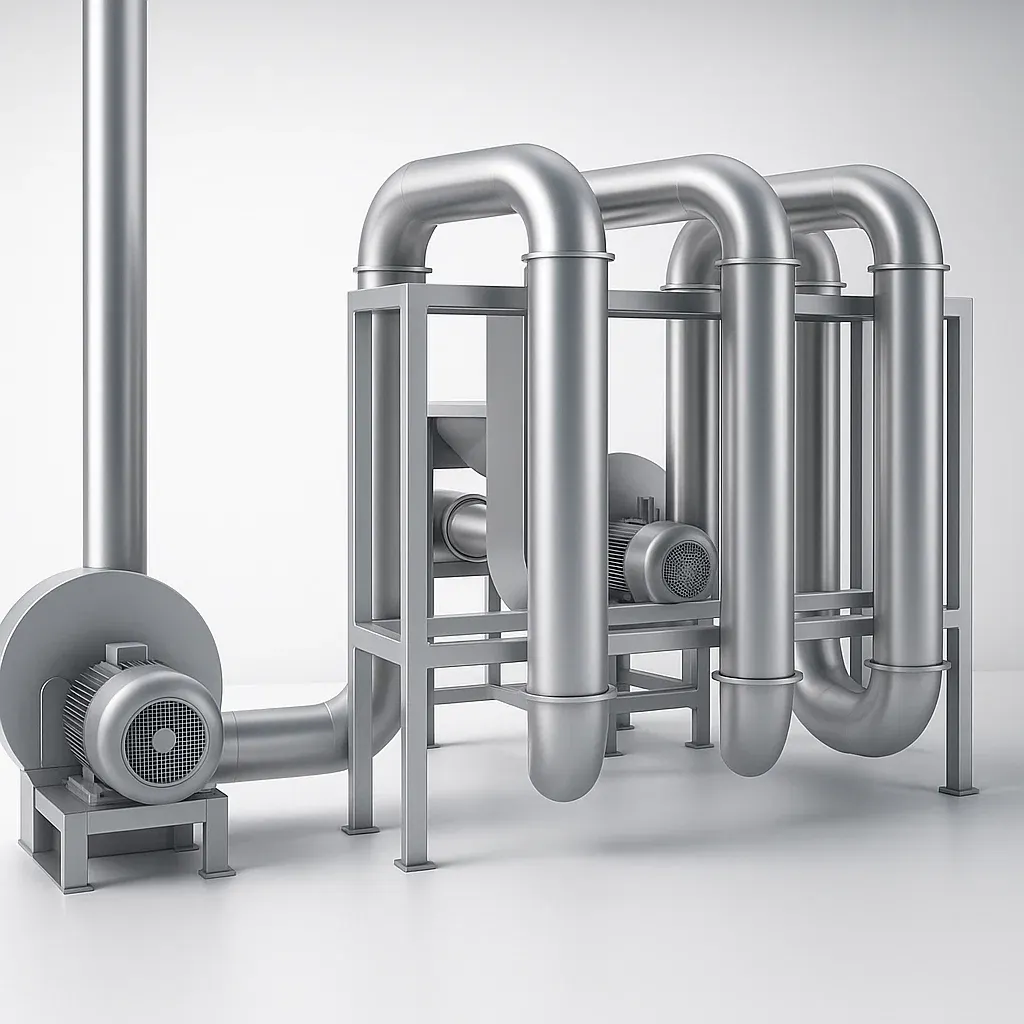

Систем за термално сушење цеви

Термални сушач цеви је последња, критична фаза у процесу сушења. Пројектован је тако да испари последње трагове влаге из ПЕТ пахуљица, постижући ултра низак садржај влаге потребан за висококвалитетну екструзију и друге захтевне примене.

Функција

Након механичког одводњавања, пахуљице се пнеуматски транспортују у дугачку мрежу загрејаних цеви од нерђајућег челика. Снажан вентилатор гура прецизно загрејани ваздух кроз систем, транспортујући пахуљице заједно са њима. Дугачка дужина цеви обезбеђује довољно „време задржавања“, омогућавајући врућем ваздуху да темељно загреје сваку пахуљицу и испари сву преосталу површинску и унутрашњу влагу. Смеша затим улази у циклонски сепаратор, који одваја сада суве пахуљице од врућег, влажног ваздуха. Коначно, систем за хлађење транспортује пахуљице до силоса за складиштење, смањујући њихову температуру како би се спречило згрушавање или промена боје.

Техничке карактеристике

- Опсежне цеви од нерђајућег челика: Направљено у потпуности од висококвалитетног нерђајућег челика како би се спречила контаминација рђом и обезбедио дуг век трајања. Дужина је пројектована за оптималан пренос топлоте и време задржавања.

- Прецизан систем за контролу температуре: Аутоматизовани систем који одржава константну температуру сушења, која се може подесити тако да одговара различитим захтевима материјала.

- Високоефикасни вентилатор и грејач: Моћан и поуздан систем за ваздух дизајниран за енергетски ефикасан рад.

- Интегрисани циклонски сепаратор и хлађење: Комплетан систем на крају линије који ефикасно одваја, хлади и транспортује финални, висококвалитетни производ до вашег силоса за складиштење.

Силос за складиштење производа

Силос за производе је последња тачка за сакупљање и складиштење у линији за рециклажу. Дизајниран је за безбедно складиштење висококвалитетних, готових ПЕТ пахуљица, а истовремено делује као кључни тампон за ефикасан процес паковања.

Функција

Чисте, суве пахуљице се пнеуматски транспортују из циклонског сепаратора система за сушење директно на врх силоса. Силос акумулира готов производ, омогућавајући линији прања и сушења да непрекидно ради, чак и ако је процес паковања привремено паузиран. Конусовидно дно обезбеђује глатко и равномерно пражњење пахуљица у станицу за пуњење великих врећа (FIBC) или транспортни систем.

Техничке карактеристике

- Прилагодљиви капацитет: Силоси су доступни у различитим величинама (нпр. 1-5 кубних метара) и могу се прилагодити пропусном капацитету ваше линије за прање и вашим захтевима за складиштење.

- Опција резервоара од нерђајућег челика: Главни резервоар за складиштење може бити направљен од нерђајућег челика како би се осигурала максимална чистоћа и спречила било каква контаминација финалног производа.

- Интегрисани сензори нивоа: Опциони сензори високог и ниског нивоа могу се инсталирати како би се аутоматизовао ток производње и упозорили оператери када је силос пун или скоро празан.

- Робустан носећи оквир: Челични оквир издржљивости дизајниран за стабилност и обезбеђивање довољног простора за лако постављање и вађење великих врећа.

Обрада са додатом вредношћу: Линија за пелетирање ПЕТ-а

Иако су висококвалитетне ПЕТ пахуљице вредна роба, њихово претварање у униформне пелете отвара врата ка премиум тржиштима и применама. Наше напредне линије за пелетирање су пројектоване да трансформишу чисте пахуљице у густ, једноставан за руковање и веома конзистентан финални производ.

Функција

Чисте, суве пахуљице се доводе у екструдер, где прецизно пројектовани шраф топи, притиска и хомогенизује материјал. Растопљена пластика се пропушта кроз високоефикасан систем филтрације како би се уклониле све коначне нечистоће, а затим се екструдира кроз главу за пресовање да би се формирале конзистентне нити. Ове нити се одмах хладе у воденом купатилу, а затим секу у једноличне, цилиндричне пелете помоћу пелетизатора велике брзине.

Техничке карактеристике

- Конфигурације са једним и два завртња: Нудимо и једнопужне екструдере за стандардно пелетирање и високоперформансне двопужне екструдере за врхунско мешање, компаундирање и руковање захтевнијим материјалима.

- Напредна дегазација и филтрација: Опремљен вакуумским дегазационим отворима за уклањање испарљивих материја и хидрауличним мењачем сита за континуирану филтрацију растопљеног материјала без прекида производње.

- Високоефикасан систем за пелетирање жица: Укључује водено купатило од нерђајућег челика за брзо хлађење и брзи пелетизатор за производњу чистих, уједначених пелета.

- Интегрисана PLC паметна контрола: Централни систем управљања са екраном осетљивим на додир управља свим параметрима, од температуре грејања до брзине шрафа и брзине сечења, обезбеђујући стабилан рад и конзистентност серије.

Техничке спецификације

| Влага | <0,9% |

|---|---|

| ПВЦ | <50 ппм |

| Лепак | <10 ппм |

| ПП/ПЕ | <20 ппм |

| Метал | <20 ппм |

| Ознака | <20 ппм |

| Пахуљица у боји | <30 ппм |

| ПХ | Неутрално |

| Укупна нечистоћа | <100 ппм |

| Величина пахуљица | 12 мм, 16 мм или прилагођено |

| Капацитет (кг/х) | Инсталирана снага (kw) | Потребна површина (㎡) | Потребно особље | Потребна пара (кг/х) | Потребан компримовани ваздух (Mpa) | Потребна вода (м³/х) |

|---|---|---|---|---|---|---|

| 500 | 220 | 400 | 8 | 350 | 0.6-0.8 | 1 |

| 1000 | 500 | 750 | 10 | 500 | 0.6-0.8 | 3 |

| 2000 | 700 | 1000 | 12 | 800 | 0.6-0.8 | 5 |

| 3000 | 900 | 1500 | 12 | 1000 | 0.6-0.8 | 6 |

| 4500 | 1000 | 2200 | 16 | 1300 | 0.6-0.8 | 8 |

| 6000 | 1200 | 2500 | 16 | 1800 | 0.6-0.8 | 10 |

Зашто сарађивати са Energycle-ом

Избор правог система рециклаже је кључна инвестиција у вашу оперативну ефикасност и дугорочну профитабилност. У Energycle-у не продајемо само машине; ми пројектујемо свеобухватна, високо ефикасна решења и градимо трајна партнерства посвећена вашем успеху.

Прилагођена решења по принципу „кључ у руке“

Разумемо да је свака операција јединствена. Наш стручни инжењерски тим тесно сарађује са вама како би дизајнирао и интегрисао систем савршено прилагођен вашим потребама.

Бескомпромисни квалитет излаза

Наше напредне технологије производе ПЕТ пахуљице врхунског квалитета са нивоом чистоће који прелази 99%, осигуравајући да ваш производ поседује већу тржишну вредност.

Робустан и ефикасан инжењеринг

Оптимизовано за смањење потрошње и ниже оперативне трошкове, уз максимално време рада и повраћај улагања.

Свеобухватно постпродајно партнерство

Професионална инсталација

Стручно подешавање на лицу места за савршен рад од првог дана.

Обука оператера

Оснажите свој тим оперативним знањем.

Резервни делови

Робустан инвентар за минимизирање застоја.

Техничка подршка

Доживотна помоћ од искусних техничара.

Изаберите Energycle за поуздано, дугорочно партнерство посвећено претварању отпада у вредност.

Ваше ултимативно решење за рециклажу пластике за ПЕТ боце – Позив на акцију

Решење за рециклажу пластике је посебно дизајнирано за рециклажу пластике, са напредном опремом за рециклажу, усмереном на повећање ефикасности рециклаже ПЕТ боца како би се унапредило ваше пословање!

Често постављана питања

Добијте одговоре на честа питања о нашој машини за рециклажу

Машина за рециклажу ПЕТ флаша је специјализована опрема дизајнирана за прераду коришћених полиетилен терефталатних (ПЕТ) флаша и њихово претварање у сировине за поновну употребу. Ова машина обично обавља функције попут уситњавања, прања, сушења и пелетизирања, ефикасно припремајући ПЕТ за поновну производњу у нове производе као што су влакна, контејнери или аутомобилски делови. Ефикасан рад машине за рециклажу ПЕТ флаша не само да помаже у смањењу пластичног отпада, већ и подржава еколошки прихватљиве праксе промовисањем циркуларне економије.

Рад машине за рециклажу ПЕТ боца генерално укључује неколико кључних корака. Прво, машина сакупља и убацује ПЕТ боце у дробилицу, где се разбијају на мање комаде. Затим се ови комади перу како би се уклонили загађивачи попут етикета, лепкова и прљавштине. Након прања, чисте ПЕТ пахуљице се суше и често пелетизирају, претварајући их у мале пелете или грануле које произвођачи могу користити за стварање нових производа. Читав процес помаже у смањењу утицаја на животну средину и очувању ресурса.

Коришћење машине за рециклажу ПЕТ флаша пружа бројне предности. Пре свега, значајно доприноси смањењу пластичног отпада на депонијама и у океанима, борећи се против загађења. Поред тога, рециклажа ПЕТ-а штеди природне ресурсе и енергију у поређењу са производњом новог ПЕТ-а од необрађених материјала. Ова машина такође подстиче економске могућности стварањем радних места у индустрији рециклаже. Претварањем отпада у функционалне материјале, подржава напоре за одрживост и подстиче одговорну потрошњу, што у крајњој линији користи животној средини и друштву.

Већина машина за рециклажу ПЕТ флаша може да обрађује широк спектар ПЕТ флаша, укључујући оне које се користе за пића, кућне производе и предмете за личну негу. Међутим, кључно је осигурати да се ове флаше адекватно очисте како би се уклониле све преостале течности или загађивачи. Етикете направљене од папира или пластике се обично могу обрађивати; међутим, јако лепљива или вишеслојна амбалажа може захтевати додатне технике обраде. Упознавање са спецификацијама машине може оптимизовати процес рециклаже.

Цена машине за рециклажу ПЕТ флаша може значајно да варира у зависности од фактора као што су величина, капацитет, ниво аутоматизације и додатне функције. Мали, основни модели могу почети од неколико хиљада долара, док напредније и веће машине могу достићи десетине или чак стотине хиљада долара. Компаније морају узети у обзир свој обим рециклаже и оперативне захтеве приликом избора машине. Препоручљиво је спровести темељно истраживање и упоредити опције реномираних произвођача како би се осигурала вредност за инвестицију.

Машине за рециклажу ПЕТ флаша могу се купити од компаније Rumtoo Machinery, специјализованог произвођача и добављача који се фокусира на технологију рециклаже. Као добављач индустријских машина, Rumtoo Machinery има посебну дивизију за опрему за рециклажу. Важно је одабрати овог реномираног добављача познатог по квалитету и корисничкој услузи. Поред тога, истраживање онлајн тржишта и посета сајмовима могу понудити широк спектар опција. Штавише, контактирање локалних организација за рециклажу може довести до вредних препорука и увида у најбоље машине за ваше специфичне потребе.

-Display.webp?fit=crop&ar=1:1&auto=format,compress&fm=webp)