Știri despre reciclare

Selecting the ideal plastic granulator is a critical investment that can significantly impact your operation's efficiency and profitability. Energycle's granulatoare de plastic combine precision engineering with durability to handle demanding recycling applications. This comprehensive guide will help you identify the perfect machine for your specific needs.

Plastic film recycling is an essential aspect of modern waste management, addressing the growing challenge of managing lightweight, flexible plastic waste. This survey note provides an in-depth exploration of film recycler machines, their features, benefits, and operational mechanisms, drawing on extensive research to ensure a thorough understanding for both industry professionals and lay readers.

When it comes to maximizing dewatering efficiency for plastic films—think polyethylene (PE) or polypropylene (PP)—the equipment you choose can make or break your recycling operation. These machines aren’t just tools; they’re investments in quality output, cost savings, and sustainability. Let’s break down the standout features, benefits, and qualities of mechanical dewatering equipment, focusing on what matters most to businesses in this space.

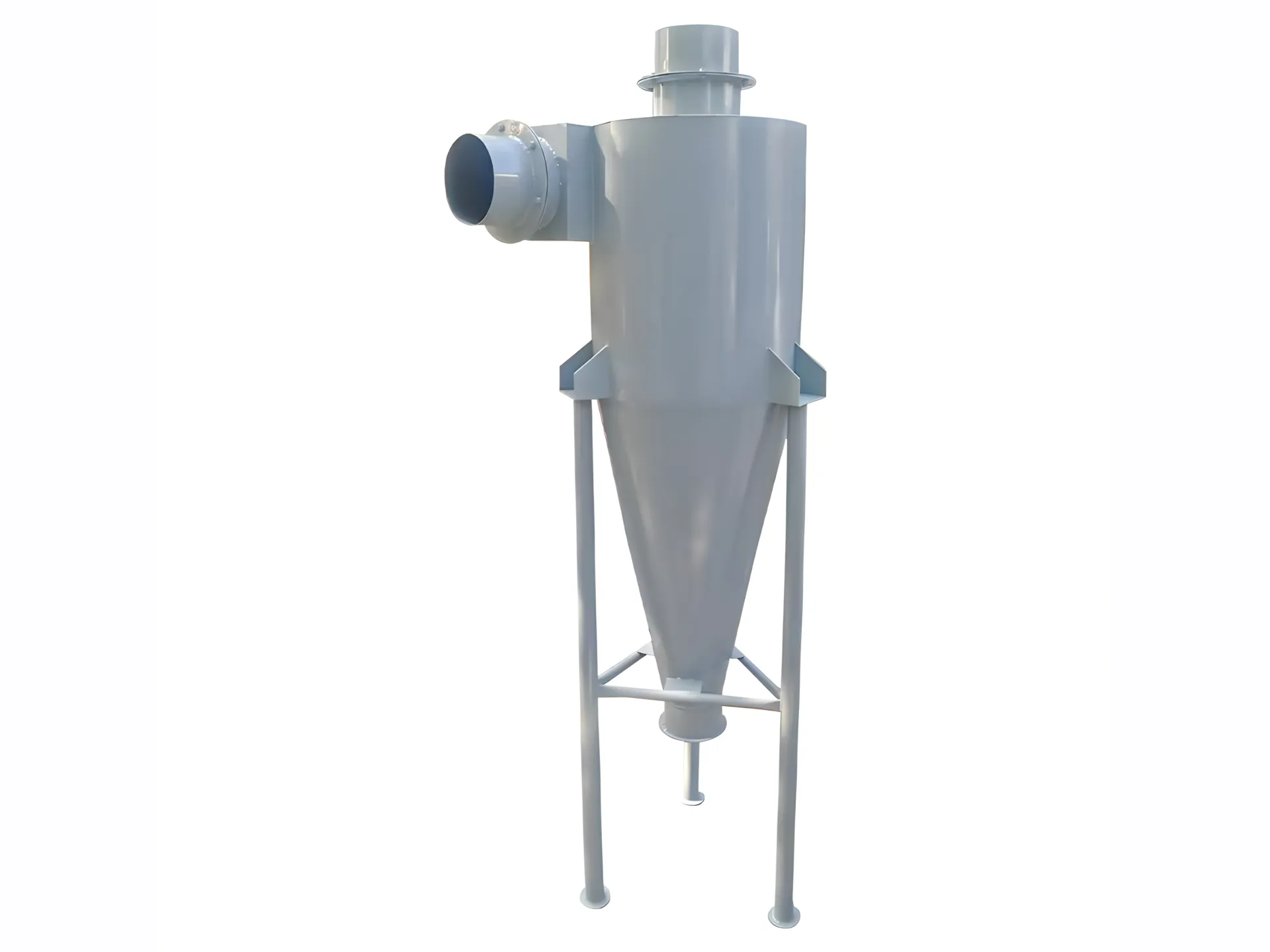

Cyclone Separators in Plastic Recycling: Key Mechanisms & Applications

Cyclone separators are critical in plastic recycling for efficiently sorting and purifying materials by leveraging differences in particle density, size, and airflow dynamics. Here’s how they are tailored to meet industry-specific needs:

Tire recycling is an essential process in managing the increasing volume of discarded tires. A critical step in this process involves cutting the sidewall of the tire. Understanding the rationale behind this step highlights its significance in the recycling chain and its impact on material recovery and equipment efficiency.

For small businesses, selecting the right plastic recycling equipment requires balancing cost, efficiency, and long-term operational needs. Here are practical suggestions from the perspectives of core functions, applicable scenarios, and cost-effectiveness.

Tire recycling plays a pivotal role in addressing the global environmental crisis caused by the disposal of millions of used tires annually. With over 56 million tires processed each year in many countries, establishing effective tire recycling systems is essential for sustainable waste management and environmental preservation.

Addressing the global challenge of plastic waste, polyethylene terephthalate (PET) stands out due to its widespread applications and recyclability. Efficient PET recycling systems are crucial for realizing a circular economy and reducing reliance on virgin resources. This article provides a professional overview of the core components of a PET recycling machine, elucidating how these essential modules work in concert to transform post-consumer PET materials into high-quality recycled feedstocks. We will delve into the equipment configurations of critical stages including pre-processing, washing, sorting, and extrusion pelletizing, briefly analyzing the technical specifications and performance metrics of each section. This aims to offer industry professionals a deeper understanding of the PET recycling process flow and equipment composition.

Foam recycling has become a critical component of sustainable manufacturing practices, particularly for industries dealing with expanded polystyrene (EPS) and other foam materials. Investing in foam recycling machinery offers manufacturers a dual advantage: reducing environmental impact and achieving significant cost savings. This analysis explores the costs, benefits, and strategic considerations for manufacturers contemplating such an investment.