The Pipeline Hot Air Drying System is a cutting-edge industrial solution designed to optimize the processing of plastic materials by effectively reducing moisture content. Engineered for durability, energy efficiency, and precision, this system meets the rigorous demands of the plastic recycling industry. Below, we explore its standout features, advantages, and unparalleled quality, tailored specifically for plastic recycling applications.

Key Features of the Pipeline Hot Air Drying System

Superior Moisture Reduction

The system efficiently lowers the moisture content of plastic flakes or pellets to below 2%, ensuring optimal dryness for downstream processing. This capability minimizes clumping, degradation, and quality issues, making it ideal for moisture-sensitive plastics such as PET, HDPE, and PP.

Energy-Efficient Insulation

Equipped with high-grade insulation materials, the system significantly reduces thermal energy loss. This design not only conserves energy but also maintains consistent temperatures, enhancing drying performance and reducing operational costs.

Powerful Airflow Performance

An 11 kW fan ensures rapid and uniform hot air circulation throughout the 30-meter pipeline. This guarantees efficient heat distribution, reducing processing time while preserving the integrity of plastic materials.

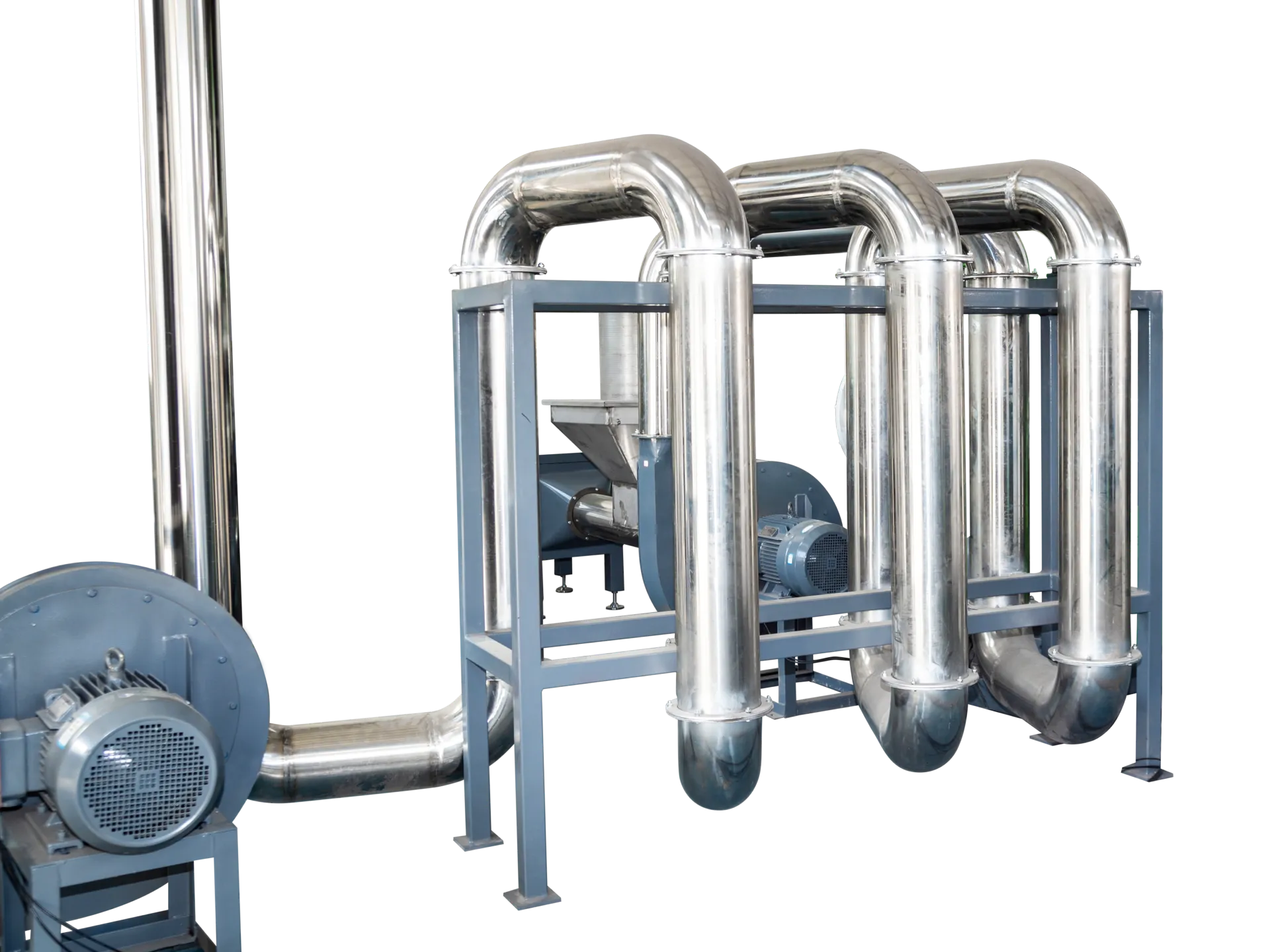

Robust Stainless Steel Construction

- Pipeline Specifications:

- Diameter: 219 mm

- Wall Thickness: 2 mm

- Material Contact Parts: Made of SU304 stainless steel, offering exceptional corrosion resistance, hygiene, and compliance with industrial standards for plastic recycling.

High-Capacity Heating

With a 72 kW heating power, the system delivers rapid temperature elevation, ensuring quick and thorough drying even for high-volume plastic recycling production lines.

Durable Frame Structure

The frame is constructed from carbon steel (6*6*3 mm square tube), providing exceptional structural stability and longevity in demanding industrial environments.

Advantages of the Pipeline Hot Air Drying System

✅ Enhanced Productivity

The combination of a 30-meter pipeline and 72 kW heating power enables large-scale processing of plastic materials with minimal downtime, boosting throughput for recycling operations.

✅ Cost Savings

The energy-efficient insulation reduces energy consumption by up to 20%, while the stainless steel components lower maintenance costs due to their resistance to wear and corrosion.

✅ Consistent Quality Output

Precise moisture control (<2%) and uniform heat distribution ensure batch-to-batch consistency, critical for producing high-quality recycled plastics.

✅ Easy Integration

The modular design allows seamless integration into existing plastic recycling lines, with customization options for pipeline length and heating configurations.

Uncompromising Quality & Safety

- Industrial Compliance: All material-contact parts use SU304 stainless steel, meeting stringent hygiene and safety standards for plastic recycling applications.

- Longevity: The carbon steel frame and thick-walled stainless steel pipeline resist deformation and corrosion, ensuring a lifespan exceeding 10+ years with proper maintenance.

- Safety Features: Insulated surfaces prevent external heat exposure, protecting operators and surrounding equipment.

Апликације

This system is ideal for drying:

- Plastic flakes and pellets (e.g., PET, HDPE, PP)

- Recycled plastic materials

- Post-consumer plastics

- Industrial plastic waste

Закључак

The Pipeline Hot Air Drying System stands out as a reliable, energy-efficient, and high-performance solution for plastic recycling drying needs. Its advanced engineering, durable materials, and precision moisture control make it a cost-effective investment for businesses aiming to enhance the quality of recycled plastics and improve operational efficiency.

[…] Pipe Hot Air Drying: Precision Drying for Optimal […]