Achieve premium quality in your recycled materials with our specialized drying solution. Engineered to deliver **less than 2%** moisture, this system eliminates defects, boosts throughput, and maximizes the value of your recycled flakes and granules for downstream processing.

Your Competitive Advantage

Maximize Material Value

Produce premium-grade recycled plastics that command higher prices. Our system guarantees the <2% moisture content critical for flawless pelletizing and molding.

Boost Your Throughput

The powerful 72 kW heating and 30-meter pipeline enable continuous, high-volume processing, minimizing bottlenecks in your washing line.

Lower Operational Costs

High-grade insulation reduces energy consumption by up to 20%, while the durable SU304 stainless steel construction minimizes maintenance and ensures a 10+ year lifespan.

Engineered for Performance & Reliability

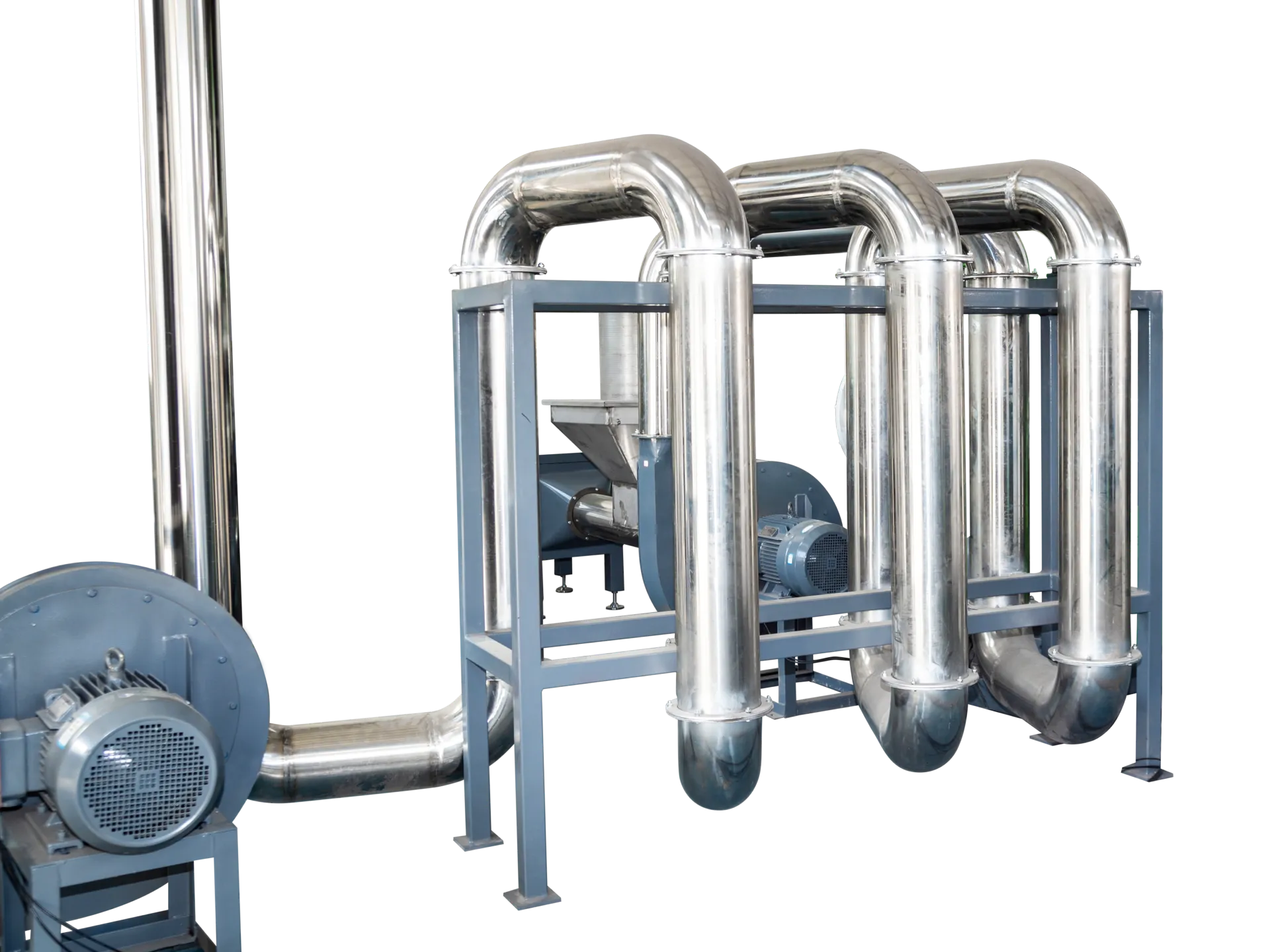

Heavy-Duty Construction for 24/7 Operation

Built to withstand the harshest industrial environments, our system combines superior materials for maximum longevity:

- Material Contact Parts: Corrosion-proof SU304 Stainless Steel prevents contamination and ensures the purity of your recycled plastics.

- Structural Frame: A robust frame from heavy-gauge carbon steel provides unwavering stability for continuous operation.

High-Velocity Thermal Performance

A powerful 72 kW heating unit and an 11 kW fan create a torrent of precisely controlled hot air. This ensures every flake and granule is dried uniformly and rapidly, slashing processing times and preserving material integrity.

Ideal Applications

This system is the perfect solution for drying a wide range of washed rigid plastics, including:

Post-consumer PET Bottle Flakes

Post-industrial HDPE Regrind

Washed PP Granules

Technical Specifications

| Target Materials | PET, HDPE, PP (Flakes, Granules, Regrind) |

| Final Moisture Content | < 2% |

| Heating Power | 72 kW |

| Fan Power | 11 kW |

| Pipeline Length | 30 meters |

| Pipeline Diameter | 219 mm |

| Pipeline Wall Thickness | 2 mm |

| Material Contact Parts | SU304 Stainless Steel |

| Frame Material | Carbon Steel (60x60x3 mm) |

See It In Action

Ready to Elevate Your Recycled Plastic Quality?

Stop letting moisture compromise your output. Contact our specialists today to discuss your specific drying needs, customize a system for your production line, and receive a detailed quote.

[…] Pipe Hot Air Drying: Precision Drying for Optimal […]