Efficient Screw Press Dewatering System

Discover our robust Screw Press Dewatering System, specifically engineered for demanding PE film washing lines. This highly effective solution efficiently extracts moisture from your material stream, offering a significant advantage over traditional methods. Its versatility is proven across various industries, including food processing, paper & pulp, and wastewater treatment. Experience outstanding moisture reduction with this durable machine, providing a powerful, cost-effective alternative to energy-intensive thermal heaters.

How It Works: The Ingenious Principle

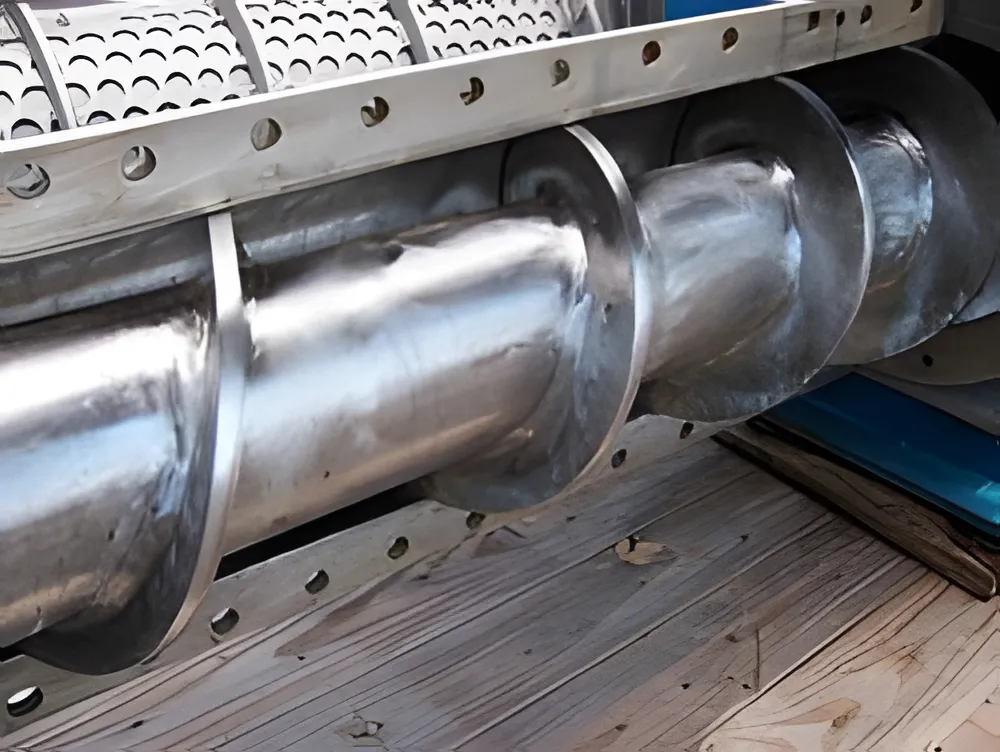

At the heart of our dewatering system lies an intelligently designed screw shaft featuring a progressively increasing diameter. Material enters via the vertical feeder where the shaft is narrowest.

As the screw shaft gently rotates, it advances the wet plastic feedstock forward. Simultaneously, the increasing shaft diameter gradually compresses the material against the robust outer casing. This casing, a thick-walled tube of uniform diameter, is lined with fine perforations meticulously designed for optimal water drainage.

The applied pressure effectively squeezes moisture from the plastic, which escapes through these perforations. While our standard industrial recycling screw presses are typically 4-6 meters long, we can customize the length to perfectly match your operational requirements.

Towards the end of its journey, the screw shaft’s diameter nearly matches the inner diameter of the casing. The dried plastic material exits through this precisely engineered narrow gap. A well-optimized system like ours reliably reduces moisture content to below 15%, preparing your material for the next stage.

Explore the Details

Ready to Boost Your Efficiency?

Contact us today for the latest pricing, lead times, and to discuss how our Screw Press Dewatering System can meet your specific needs. Simply fill out the form below, and our team will get back to you promptly.