تبدأ عملية إعادة تدوير زجاجات البولي إيثيلين تيريفثالات بشكل فعال باستخدام الآلات المناسبة - آلة تحبيب زجاجات PET تلعب هذه الآلة الأساسية دورًا محوريًا في هذه العملية. فهي تُحوّل زجاجات البولي إيثيلين تيريفثالات الضخمة إلى رقائق بلاستيكية صغيرة وسهلة الاستخدام، ويسهل التعامل معها وإعادة تدويرها. في هذا الدليل الشامل، ستتعرف على كل ما يتعلق بحبيبات البولي إيثيلين تيريفثالات: كيفية عملها، وفوائدها، وميزاتها الرئيسية، ونصائح لاختيار الحبيبة المثالية لاحتياجات إعادة التدوير.

ما هي آلة تحبيب الزجاجات البلاستيكية؟

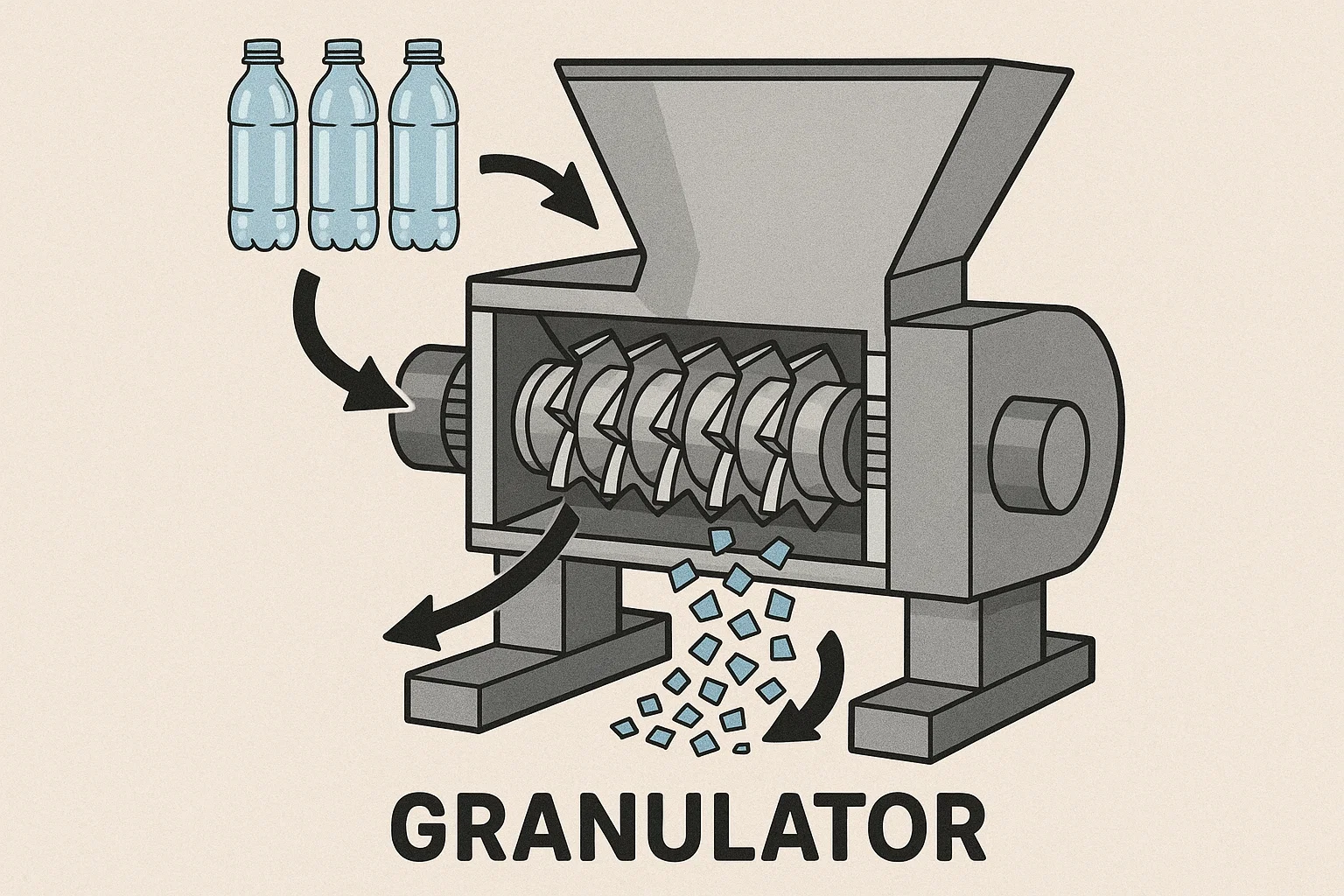

أ محبب آلة صناعية مصممة خصيصًا لتقطيع زجاجات البولي إيثيلين تيريفثالات إلى رقائق بلاستيكية صغيرة. تستخدم شفرات دوارة عالية السرعة مع سكاكين ثابتة داخل حجرة تقطيع. يقطع هذا النظام الزجاجات بكفاءة إلى قطع متناسقة وموحدة، مما يجعل عملية إعادة التدوير أكثر سلاسة وفعالية.

إذا كنت تريد استكشاف خيارات مختلفة، تحقق من آلات حبيبات البلاستيك القياسية الممتازة مُصمم خصيصًا لإعادة تدوير زجاجات PET بكفاءة.

كيف تعمل حبيبات PET؟

1. تغذية الماكينة

يتم تغذية زجاجات PET إلى الحبيبات إما يدويًا أو من خلال نظام ناقل آلي، اعتمادًا على الإعداد الخاص بك.

2. عملية القطع

داخل حجرة القطع، تدور سكاكين دوارة متينة بسرعة على شفرات ثابتة. تُقطّع هذه العملية الزجاجات إلى رقائق أصغر. تضمن شبكة ذات ثقوب تتراوح عادةً بين 12 و18 مليمترًا مرور الرقائق ذات الحجم المطلوب فقط، بينما تبقى القطع كبيرة الحجم في الحجرة لمزيد من القطع.

3. الغسيل والتبريد

تتميز العديد من آلات تحبيب البولي إيثيلين تيرفثالات (PET) بنظام رش مائي يرش الماء في حجرة القطع. هذا لا يساعد فقط على غسل الرقائق، بل يقلل أيضًا من الاحتكاك، ويمنع ارتفاع درجة حرارة الشفرات ويطيل عمرها الافتراضي.

الميزات الرئيسية لجهاز تحبيب زجاجات PET

- السكاكين الدوارة عالية السرعة: المكون الأساسي الذي يقطع زجاجات PET بسرعة ودقة.

- السكاكين الثابتة: العمل مع الشفرات الدوارة للحصول على عملية قطع فعالة.

- نظام رش المياه: يقوم بتنظيف الرقائق أثناء المعالجة ويقلل من تآكل الشفرة.

- الشاشة والمناخل: تأكد من اتساق حجم الرقاقة لتحسين المعالجة اللاحقة.

اكتشف المزيد عن ميزات ونماذج منتجاتنا آلات حبيبات البلاستيك هنا.

فوائد استخدام آلة تحبيب زجاجات البولي إيثيلين تيريفثالات

- كفاءة عالية: يقلل بسرعة من حجم زجاجات PET إلى رقائق، مما يسرع عملية إعادة التدوير.

- تخفيض الحجم: يقلل بشكل كبير من حجم النفايات، مما يسهل النقل والتخزين.

- التنوع: يتعامل مع أنواع مختلفة من البلاستيك بالإضافة إلى مادة PET، بما في ذلك مادة HDPE وPP.

- تحسين النظافة: يؤدي الغسيل المتكامل إلى تقليل الملوثات، مما يعزز جودة الرقائق المعاد تدويرها.

كيفية اختيار حبيبات PET المناسبة

ضع في اعتبارك قدرتك على المعالجة

قم بتقييم إنتاجية آلة التحبيب - عدد الكيلوجرامات أو الأطنان التي يمكنها معالجتها في الساعة - لتتناسب مع حجم إعادة التدوير لديك.

التحقق من حجم حجرة القطع

تأكد من أن الغرفة تستوعب أحجام الزجاجات التي تتعامل معها، حتى لا تحتاج إلى قطع مسبق مكثف.

جودة الشفرة مهمة

ابحث عن شفرات فولاذية متينة وعالية الجودة. تعرّف أيضًا على سهولة شحذ الشفرات أو استبدالها، فالشفرات الباهتة تقلل من كفاءتها.

كفاءة الطاقة

اختر نموذجًا يوازن بين الأداء وانخفاض استهلاك الطاقة لتوفير تكاليف التشغيل.

مميزات اضافية

- تقليل الضوضاء: تحتوي بعض الحبيبات على تقنيات امتصاص الضوضاء من أجل تشغيل أكثر هدوءًا.

- سهولة الصيانة: إن الآلات المصممة لسهولة التنظيف والصيانة تقلل من وقت التوقف والتكاليف.

استكشف مجموعتنا من حبيبات بلاستيكية مُحسّنة لتلبية احتياجات مختلفة للعثور على أفضل ملاءمة.

الأسئلة الشائعة

س1: ما هي المدة التي يجب فيها استبدال الشفرات؟

ج١: يعتمد ذلك على تكرار الاستخدام وجودة الشفرة. قد تدوم الشفرة عالية الجودة لعدة أشهر، بينما قد تحتاج شفرات أخرى إلى استبدال متكرر.

س2: هل يمكن للحبيبات التعامل مع البلاستيك غير مادة البولي إيثيلين تيريفثالات؟

ج2: نعم، العديد منهم قادرون على معالجة HDPE وPP وPVC وأنواع البلاستيك الأخرى.

س3: هل غسل زجاجات PET مسبقًا ضروري؟

ج3: على الرغم من أنه ليس إلزاميًا، فإن الغسيل المسبق يساعد على تحسين جودة الرقائق ويقلل من التآكل على الشفرات.

س4: ما هي أحجام الرقائق التي تنتجها حبيبات PET؟

A4: عادةً، يتراوح حجم الرقائق من 12 إلى 18 مليمترًا، ويتم التحكم فيه من خلال حجم الشاشة.

س5: ما هي كمية المياه المستخدمة في نظام الغسيل؟

ج5: يختلف استخدام المياه حسب تصميم الماكينة؛ حيث تم تحسين الحبيبات الحديثة لتكون موفرة للمياه.

س6: هل يمكن للآلات الحبيبية معالجة زجاجات PET ذات الملصقات؟

ج6: نعم، ولكن عادةً ما تتم إزالة الملصقات لاحقًا في خط إعادة التدوير لضمان نقاء الرقائق.

خاتمة

أ آلة تحبيب زجاجات PET يُعدّ التحبيب عنصرًا أساسيًا في أي عملية إعادة تدوير بلاستيك. فهو يُعزز الكفاءة، ويُقلل من حجم النفايات، ويُحسّن نظافة وجودة رقائق البولي إيثيلين تيريفثالات المُعاد تدويرها. إن فهم آلية عمل المُحبّبات والميزات التي يجب إعطاؤها الأولوية يُساعدك على اتخاذ الخيار الأمثل لأعمال إعادة التدوير الخاصة بك. استثمر في مُحبّب موثوق واتخذ خطوة حاسمة نحو إعادة تدوير زجاجات البولي إيثيلين تيريفثالات المُستدامة والفعّالة.

لمزيد من المعلومات حول منتجاتنا، يرجى زيارة موقعنا آلات حبيبات البلاستيك الممتازة صفحة.