The global demand for recycled plastics is skyrocketing, driven by strict environmental regulations and a manufacturing shift toward sustainability. Among the various waste streams, agricultural film (LDPE/LLDPE) represents one of the most abundant yet difficult resources to recover. Used mulch films, greenhouse covers, and banana bags are often heavily contaminated with sand, soil, grass, and moisture.

Standard recycling lines often fail under these conditions, leading to frequent machine jamming, rapid blade wear, and poor-quality output. To convert this challenging waste into high-quality granules, you need a robust, engineered solution. Energycle provides a comprehensive Agricultural Film Recycling Washing Line designed specifically to handle high-contamination loads while maintaining energy efficiency.

The Challenge of Agricultural Film Waste

Unlike post-industrial waste, which is relatively clean, post-consumer agricultural film comes with specific hurdles:

- High Sediment Content: Mulch film can contain up to 40-50% sand and soil by weight.

- Thin & Stretchy Material: LDPE film easily wraps around rotors and shafts if not processed by specialized shredders.

- Moisture Retention: Water trapped in the folds of the film makes drying difficult, affecting the final pellet quality.

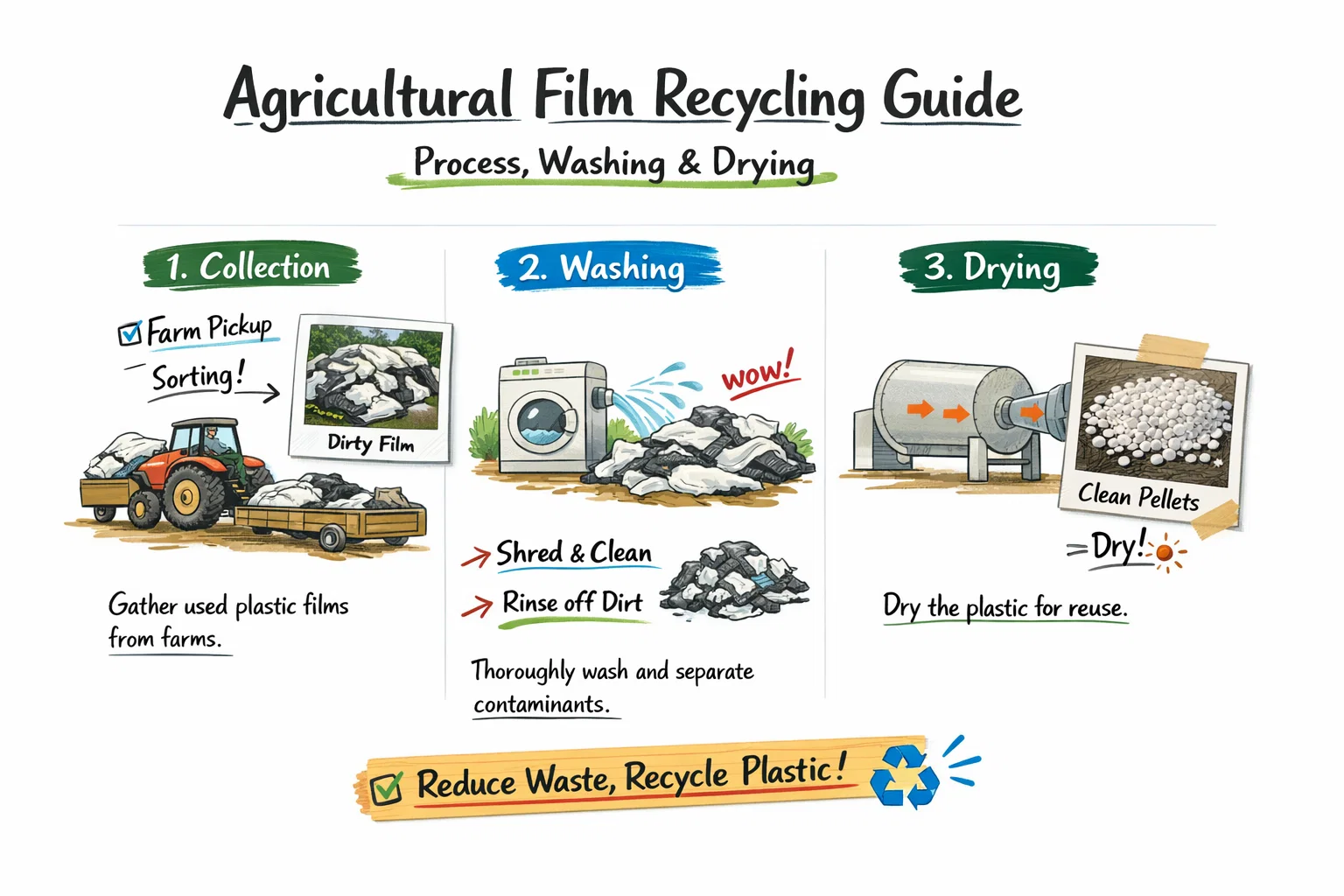

Addressing these issues requires a multi-stage process: size reduction, separation, intensive friction washing, and thermal drying.

Stage 1: Pre-Treatment and Size Reduction

The first step in any efficient recycling line is size reduction. For agricultural film, standard crushers often struggle. Energycle utilizes specialized equipment to ensure consistent feeding and shredding without jamming.

For heavy-duty applications, we recommend integrating our آلة تقطيع مخلفات البلاستيك. This unit is engineered to handle soft, tangled materials that typically choke standard granulators.

- Anti-Winding Design: The rotor configuration prevents film from wrapping around the shaft, a common downtime cause in generic machines.

- Wear-Resistant Blades: Given the abrasive nature of sand-covered film, our blades are treated for high durability, reducing maintenance frequency.

- Uniform Output: Consistent flake size is crucial for the efficiency of the subsequent washing stages.

For facilities handling a mix of materials, our آلة تقطيع المواد الناعمة ذات العمود الواحد offers the versatility needed to switch between varied feedstock densities without compromising throughput.

Stage 2: High-Efficiency Washing System

Once shredded, the material moves to the core of the operation: the washing system. This is where the value is created. Energycle’s washing line employs a multi-step friction and floating washer system to separate contaminants effectively.

غسيل احتكاكي عالي السرعة

The material enters a high-speed friction washer. Here, rotating paddles generate intense kinetic energy, scrubbing the film flakes against each other and the screen mesh. This action mechanically dislodges stubborn dirt, sand, and organic matter adhering to the plastic surface.

- القوة الطاردة المركزية: Dirty water and small contaminants are ejected through the mesh screens, preventing re-contamination.

- التشغيل المستمر: The system is designed for 24/7 operation with automated water filtration integration.

خزانات فصل الغاطس والطفو

After friction washing, the material enters large separation tanks. Since LDPE/LLDPE floats on water while heavier contaminants (stones, metals, glass, heavy plastics) sink, this stage ensures a high purity level of the film flakes.

- Multiple Tanks: For heavily soiled agricultural film, we utilize a series of floating tanks to ensure multiple wash cycles.

- Rolling Drums: Heavy-duty rollers push the material submerged to ensure thorough wetting and cleaning before it floats back to the surface for extraction.

Stage 3: Advanced Drying Technology

Wet film flakes are notoriously difficult to dry due to their surface area and tendency to hold water. Traditional hot air dryers consume immense amounts of energy. Energycle solves this with a mechanical Squeezing Dryer.

This machine uses a screw press mechanism to physically squeeze water out of the washed film flakes.

- Low Moisture Content: Our squeezing dryers can reduce moisture levels to below 3-5%, making the material immediately ready for the pelletizing extruder.

- توفير الطاقة: By using mechanical pressure rather than thermal heat as the primary drying method, you significantly reduce electricity consumption.

Versatility in Recycling Solutions

While this guide focuses on agricultural film (LDPE), many recycling facilities handle a diverse range of soft plastics. It is important to note that the principles of washing and shredding often overlap with other materials, such as woven sacks.

If your facility also processes polypropylene materials, such as cement bags or jumbo bags, we offer specialized setups for these streams. You can learn more about our dedicated solutions for PP Woven Bags/Raffia Recycling Lines, which utilize similar robust shredding technologies but feature washing parameters adjusted for PP density and characteristics.

Whether you are processing Heavy Duty HDPE Plastic Pipe or soft LDPE films, Energycle ensures that the machinery configuration matches the specific melt flow index (MFI) and contamination levels of your raw material.

Why Choose Energycle for Your Ag-Film Line?

Investing in a recycling line is a significant capital expenditure. Here is why industry leaders trust Energycle:

- Customized Engineering: We don’t sell “one-size-fits-all.” We analyze your specific film waste—whether it’s thin greenhouse film or thicker silage wrap—and configure the آلة تمزيق ذات دلو ثابت وعمود واحد or standard shredders accordingly.

- إدارة المياه: Our lines include integrated water filtration and circulation systems. This minimizes fresh water usage, a critical factor for operational costs and environmental compliance.

- متانة: Agricultural recycling is abusive to machinery. We use high-grade steel and top-tier electrical components (Siemens, Schneider) to ensure longevity.

- الأتمتة: From the belt conveyor feeding to the final bagging of clean flakes (or pellets), our lines utilize smart PLC control systems to synchronize the speed of crushers, washers, and dryers, preventing bottlenecks.

The Economics of Film Recycling

The market for Recycled LDPE (rLDPE) granules is robust. Manufacturers of garbage bags, construction films, and irrigation pipes are constantly seeking high-quality recycled pellets to lower their material costs and meet “Green Content” quotas.

However, the margin is determined by the quality of your output. Dirty, bubbly, or moisture-ridden pellets command a low price. By utilizing an Energycle Agricultural Film Recycling Washing Line, you ensure:

- No degassing issues during extrusion (due to proper drying).

- يتحمل درجات حرارة أعلى (حتى 120 درجة مئوية)، مثالي للتعبئة الساخنة وأنابيب الصرف. and low ash content (due to superior washing).

- Consistent production rates, allowing you to meet buyer contracts reliably.

خاتمة

Recycling agricultural film is no longer just an environmental necessity—it is a profitable business opportunity for those equipped with the right technology. The difference between profit and loss often lies in the efficiency of your washing and drying stages.

Energycle offers the expertise and the heavy-duty machinery required to conquer the toughest contaminants. From our آلة تقطيع مخلفات البلاستيك to our advanced squeezing dryers, every component is built for performance.

Don’t let contamination limit your potential. Upgrade your facility with a solution that guarantees purity and throughput.

Ready to optimize your recycling process?

اتصل بنا اليوم for a free consultation and a customized layout design for your agricultural film recycling plant.