Inovace v plastových granulátorech, které způsobují revoluci v recyklačním průmyslu

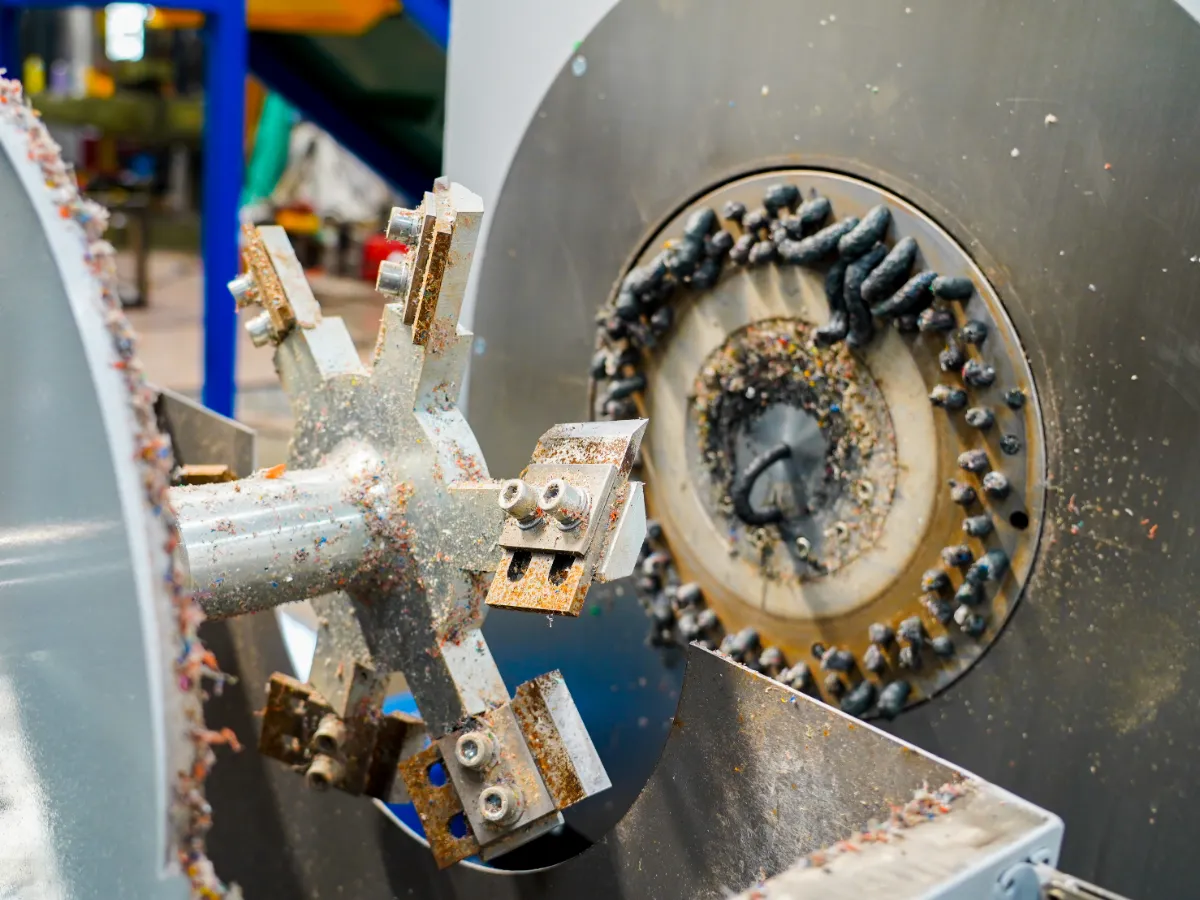

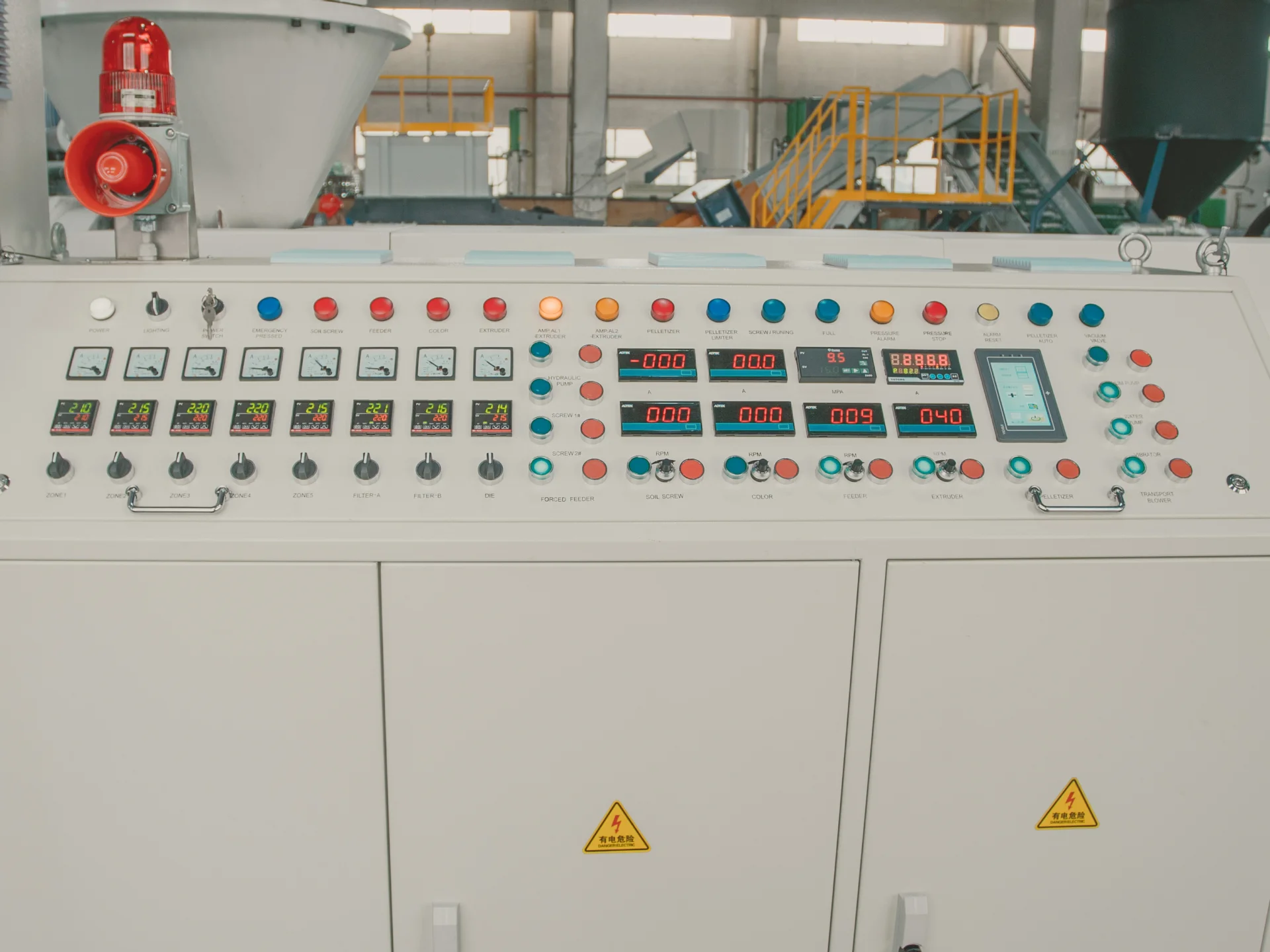

In recent years, the recycling industry has witnessed a surge of innovations in plastic granulators that are transforming the way we process and recycle plastic...