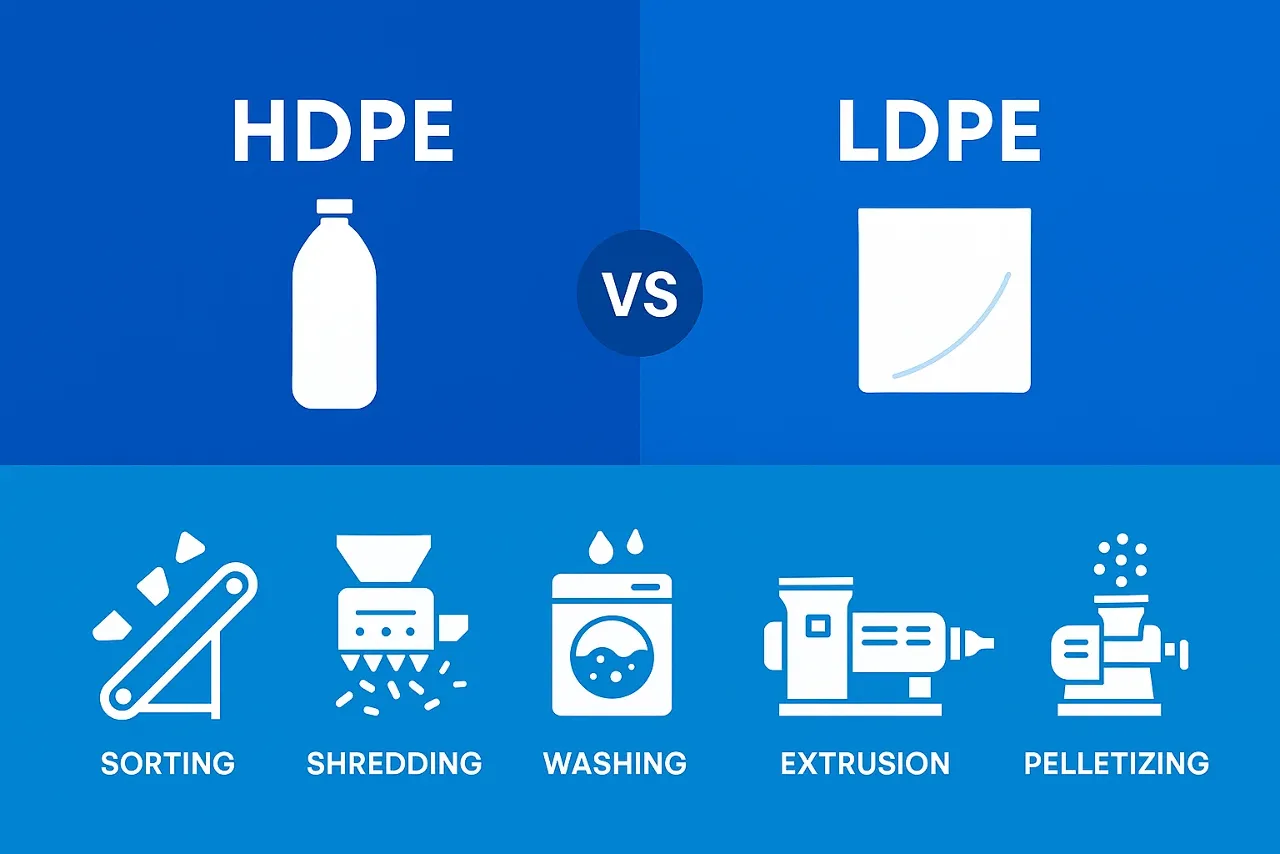

Når man designer genbrugsmaskiner, er det afgørende at forstå de forskellige egenskaber ved højdensitetspolyethylen (HDPE) og lavdensitetspolyethylen (LDPE).

Disse to plasttyper adskiller sig betydeligt i egenskaber, hvilket påvirker maskinvalg, driftsparametre og de samlede genbrugsomkostninger. Denne guide giver omfattende indsigt i, hvordan disse forskelle påvirker maskinspecifikationer, hvilket hjælper læserne med at træffe informerede beslutninger for effektive genbrugsoperationer.

A. Sortering og separation: Tilpasning af teknologier til harpiksens egenskaber

Effektiv sortering er fundamental for at producere genbrugsmaterialer af høj kvalitet. Valget af sorteringsteknologi afhænger i høj grad af, om du forarbejder stive HDPE-beholdere eller fleksible LDPE-film.

HDPE-sorteringsteknikker

HDPE har typisk en densitet på 0,941–0,970 g/cm³, hvilket gør det muligt for det at flyde i vand. Denne egenskab forenkler separation fra tættere plasttyper som PET og PVC ved hjælp af flydetanke. Derudover er nær-infrarøde (NIR) optiske sorteringsenheder effektive til at skelne mellem naturlig og farvet HDPE og adskille HDPE fra andre polymerer. Mørke pigmenter (L-værdier ≤40 eller NIR-reflektans ≤10%) kan dog reducere NIR-sorteringsnøjagtigheden. Den stive form af HDPE-produkter, såsom flasker, justeres godt med konventionelle sorteringstransportører, sigter og optiske systemer, selvom små genstande kan fjernes ved en fejl med glaspartikler i nogle faciliteter.

LDPE-sorteringsteknikker

LDPE har en lavere densitet på ca. 0,910–0,940 g/cm³, hvilket også muliggør flotationsbaseret separation. Det er dog en udfordring at skelne LDPE fra HDPE i blandede strømme. LDPE's fleksible, filmbaserede natur fører ofte til sammenfiltring og blokeringer i automatiserede systemer, hvilket reducerer sorteringseffektiviteten betydeligt. Derfor kræves specialiseret udstyr som ballistiske separatorer, luftklassificeringsapparater eller omfattende manuel sortering. Indledende sortering af LDPE er typisk baseret på dens todimensionelle filmform versus tredimensionelle beholdere.

Omkostningsmæssige konsekvenser af sortering

Sorteringsmaskiner til LDPE-film er typisk mere komplekse og dyre på grund af specialiserede funktioner, der forhindrer sammenfiltring, og den større afhængighed af manuelt arbejde. Omvendt kan HDPE-sorteringslinjer være enklere, men kræver mere robust maskineri til håndtering af stive materialer. Derfor er omkostningerne ved sorteringssystemer i høj grad drevet af harpiksformen (stiv versus film) og de ønskede renhedsniveauer.

B. Størrelsesreduktion: Tilpasning af makulatorer for optimal ydeevne

Korrekt størrelsesreduktion er afgørende før vask og ekstrudering. HDPE og LDPE kræver forskellige shredderdesigns på grund af deres forskellige mekaniske egenskaber.

HDPE-størrelsesreduktion

Stive HDPE-genstande (flasker, kasser, rør) kræver robuste kværne med højmomentmotorer, holdbare knive og kraftig konstruktion. Kværne med én aksel tilbyder præcis partikelkontrol, mens kværne med to aksler håndterer højere gennemløb og mere robuste materialer. Dette krav til kraftigere materialer resulterer i højere startomkostninger og driftsomkostninger relateret til slid på knivene.

LDPE-størrelsesreduktion

LDPE-film er udfordrende, fordi de let vikles rundt om rotorer, hvilket forårsager blokeringer og nedetid. Makulatorer, der er specielt designet til LDPE-film, har specialiserede rotorer, anti-sammenfiltringsmekanismer og præcise bladkonfigurationer. Nogle gange går densificerings- eller agglomereringsprocesser forud for makulering for at forbedre fødekonsistensen. Selvom LDPE-makulatorer kræver lavere skærekraft, medfører de højere omkostninger på grund af deres sofistikerede designfunktioner.

Omkostningsmæssige konsekvenser af størrelsesreduktion

HDPE-kværne kræver højere initiale investeringer på grund af robust konstruktion og strømkrav. LDPE-kværne er, selvom de er mindre kraftfulde, har yderligere designkompleksiteter, hvilket potentielt gør dem lige så dyre eller dyrere i visse anvendelser. Vedligeholdelse af knive er en løbende driftsudgift for begge harpikser.

C. Vask og dekontaminering: Sikring af renhed gennem skræddersyede løsninger

Effektiv vask er afgørende for fjernelse af forurenende stoffer, hvilket varierer betydeligt mellem HDPE- og LDPE-genbrugsprocesser.

HDPE vaskesystemer

HDPE kræver intensiv vask for at fjerne klæbemidler, restprodukter (fødevarer, olier), snavs og etiketrester. Friktionsvaskere, kombineret med flydende tanke, fjerner effektivt disse forurenende stoffer. Nogle systemer inkorporerer kaustiske kemiske behandlinger og højtrykssprøjter for forbedret rengøringseffektivitet.

LDPE vaskesystemer

LDPE-film, især landbrugsfilm, har en højere kontamineringsbelastning (jord, olier, kemikalier) og kræver mere komplekse vaskeprocesser i flere trin. Disse systemer kan involvere forvask, flere friktionsvasketrin og varmvask (opvarmet vand med rengøringsmidler) til genstridige forurenende stoffer. LDPE's store overfladeareal og lagdelte natur øger vanskeligheden og omkostningerne ved grundig rengøring.

Omkostningsmæssige konsekvenser af vask

LDPE-vaskeprocesser har ofte højere kapital- og driftsomkostninger på grund af kompleksiteten, energiforbruget (varmvask) og de omfattende krav til vandbehandling. HDPE-vask er generelt enklere og billigere, selvom spildevandsrensning stadig er vigtig for begge harpikser.

D. Smeltning og ekstrudering: Præcision i temperatur- og skruedesign

Smeltning og ekstrudering omdanner plastflager til pellets, og de forskellige smelteegenskaber ved HDPE og LDPE påvirker ekstruderens design betydeligt.

HDPE-ekstrudering

HDPE smelter ved højere temperaturer (120–180°C, lejlighedsvis op til 280°C), der kræver robuste varmeelementer, holdbare skrue-/tøndematerialer og effektiv isolering. Enkeltsnekkeekstrudere er typiske, selvom dobbeltsnekkedesign kan bruges til forbedret blanding.

LDPE-ekstrudering

LDPE har et lavere smeltepunkt (105–115°C), hvilket nødvendiggør præcis temperaturkontrol for at undgå nedbrydning. På grund af sin forgrenede struktur og lavere viskositet kan LDPE kræve specialiserede skruedesigns eller to-trins enkeltskrueekstrudere til intensiv filtrering, homogenisering og afgasning, især i stærkt forurenede film.

Omkostningsmæssige konsekvenser af ekstrudering

HDPE-ekstrudere har generelt et højere energiforbrug på grund af forhøjede temperaturer, hvilket fører til større driftsomkostninger. LDPE-ekstrudere kan have lavere smelteenergiomkostninger, men potentielt højere initiale kapitalinvesteringer på grund af specialiseret temperaturstyring og to-trins opsætninger, der kræves til pelletproduktion af høj kvalitet.

E. Tørring og pelletering: Sikring af pelletkvalitet gennem tilpassede processer

Tørreeffektivitet og pelleteringsmetoder påvirker direkte det endelige produktkvalitet, med unikke udfordringer forbundet med hver harpiks.

HDPE-tørring og pelletering

HDPE-flager gennemgår mekanisk centrifugaltørring efterfulgt af varmlufttørring for at opnå et lavt fugtindhold. Strengpelletering er typisk for HDPE og giver enkelhed, pålidelighed og omkostningseffektivitet.

LDPE-tørring og pelletering

LDPE-film indfanger betydelig fugtighed, hvilket kræver mere omfattende tørring (mekanisk afvanding plus termisk tørring), hvilket øger energi- og udstyrsomkostningerne. Vandringpelleteringsmaskiner, der ofte foretrækkes til LDPE, håndterer lav viskositet og klæbrighed effektivt, men kræver en højere initial investering sammenlignet med strengpelleteringsmaskiner.

Omkostningsmæssige konsekvenser af tørring og pelletering

LDPE-systemer har højere omkostninger til tørring på grund af højere fugtretention og kompleksitet. Vandringpelleteringssystemer, der typisk anvendes til LDPE, involverer større kapitaludgifter sammenlignet med HDPE's enklere strengpelleteringsopsætninger.

Oversigt over vigtige maskinovervejelser

| Maskinkomponent | HDPE-overvejelser | LDPE-overvejelser | Vigtigste omkostningsdrivere |

|---|---|---|---|

| Sortering | Robust, NIR optisk sortering til stive emner | Specialiseret ballistisk, luftseparerende og manuel sortering til film | Komplekse filmhåndteringssystemer, manuel arbejdsintensitet |

| Makulering | Højt drejningsmoment, robuste klinger til hårde materialer | Anti-tangle rotor/blad design, mulig fortætning | Højtydende og robust design (HDPE); specialiserede anti-tangle-funktioner (LDPE) |

| Vask | Intensiv friktionsvask, flyde-vask separation | Flertrins varme vaskesystemer til høj kontaminering | Kompleksitet, intensitet, energiforbrug (LDPE) |

| Tørring | Centrifugal- og varmlufttørring | Forbedret mekanisk og termisk tørring af film | Højere kapacitet og energiforbrug for LDPE-film |

| Ekstrudering | Højtemperaturkapacitet, robust skruedesign | Præcis temperaturkontrol, to-trins afgasning | Temperaturrobusthed (HDPE), præcis styring og kompleksitet (LDPE) |

| Pelletisering | Simpel strengpelletering | Vandringspelletering på grund af lav viskositet/klæbrighed | Specialiseret pelleteringsudstyr (LDPE) |

Konklusion

Det er vigtigt at forstå de unikke egenskaber ved HDPE og LDPE, når man designer eller vælger genbrugsmaskiner. Optimering af disse valg baseret på harpiksens egenskaber sikrer effektiv drift, genbrugsprodukter af høj kvalitet og omkostningseffektive genbrugsløsninger.