Transform Plastic Waste into Valuable Resources

Introducing our advanced PP/PE Regrind Washing & Pelletising Line, engineered to efficiently convert contaminated plastic film and regrind into high-quality, reusable pellets.

Why Choose Our System?

💎

High Purity Output

Achieve exceptionally clean pellets, suitable for a wide range of applications, thanks to our meticulous washing and separation processes.

⚙️

Energy Efficient Design

Optimised components and intelligent system design minimise energy consumption, reducing your operational expenditure.

🔧

Modular & Customisable

Tailor the line to your specific input materials, contamination levels, and desired output capacity for optimal performance.

From Waste to Worth: The Transformation Process

Key Equipment & Specifications

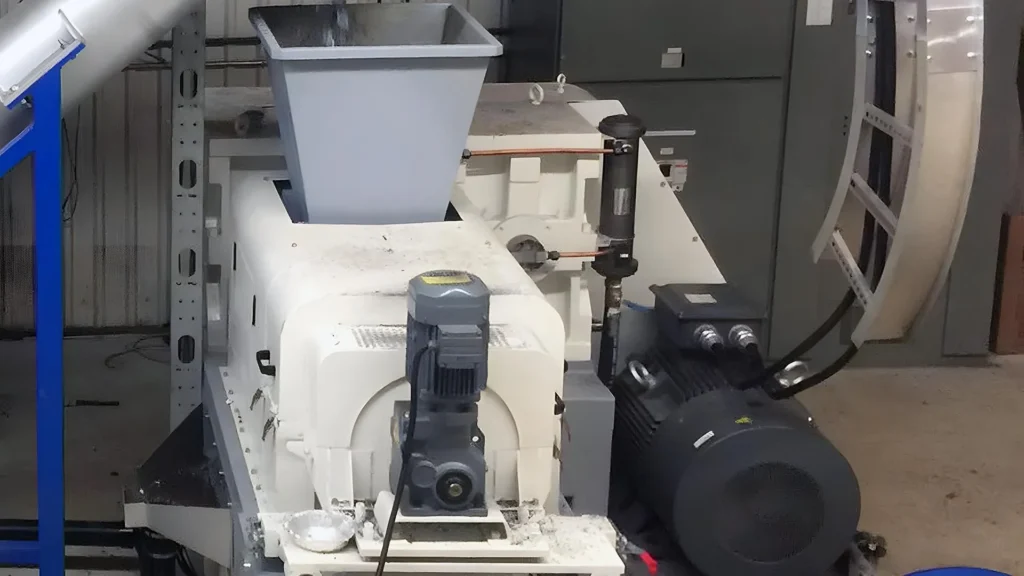

Our comprehensive washing line integrates powerful components to transform shredded PP/PE regrind into high-quality reusable pellets. This includes a friktionsskive, en effektiv flotation tank, en hurtig centrifugal tørretumbler, en innovativ squeezer, robust ekstrudere, og en præcis pelletskæresystem. Explore some key components:

Friktionsskive

The high-speed friction washer acts as a powerhouse cleaner. Its rapidly spinning shaft with angled paddles, encased in a mesh screen tunnel, dynamically scrubs materials. Strategically placed water jets ensure thorough rinsing, making it highly recommended for superior cleanliness.

Sink-Float Tank

This dual-action component is crucial for:

- Dyb rengøring: Immersion in a large water tank loosens stubborn dirt and contaminants from the plastic film.

- Smart adskillelse: Heavier debris sinks, while the valuable plastic film floats, allowing for easy separation and removal of contaminants.

Pressemaskine (Afvanding og fortætning)

Effective moisture removal is vital before extrusion. The squeezer employs mechanical force and gentle heating to compress and dry the plastic film, reducing moisture content to typically around 3%.

This not only prevents bubbles during extrusion but also densifies the material, making it ideal for feeding into the extruder and ensuring high-quality, bubble-free pellets.

This overview highlights key machinery. Remember, every recycling challenge is unique. The optimal configuration depends on your specific plastic type and contamination levels. We excel in designing custom-built lines tailored to your precise needs.

Tekniske specifikationer

- CE-certificering er tilgængelig for overholdelse af regler og ro i sindet.

- Need higher capacity? Larger, more powerful models can be custom-built upon request. Please enquire!

Visualising the Solution

Warranty & Support You Can Rely On

Your investment is protected. All our recycling machinery comes with a standard 1 års begrænset garanti, providing confidence from day one.

We offer more than just machines. Our comprehensive installationspakker include dispatching experienced engineers to your facility. They will guide your team through the entire setup process, ensuring correct commissioning for optimal performance. Should you require ongoing assistance, we can also arrange rutinemæssige vedligeholdelsesteams og driftsrådgivning to help keep your recycling plant running smoothly and efficiently for years to come. Your success is our priority.

Ofte stillede spørgsmål

What types of plastic can this line process?

This line is primarily designed for PP (polypropylene) and PE (polyethylene) materials, including post-consumer film, agricultural film, and post-industrial regrind. We can assess suitability for other similar thermoplastics upon request.

What is the typical moisture content of the final pellets?

Our advanced squeezer and drying systems are engineered to achieve a moisture content of approximately 3% or less. This is ideal for producing high-quality pellets and ensuring trouble-free downstream extrusion processes.

Can the washing line be customised?

Absolutely. We specialise in tailoring our recycling lines to meet specific client requirements. This includes adjustments for different types and levels of contamination, varying input materials, and desired output capacities and qualities.

What is the lead time for a new machine?

Lead times can vary based on the specific configuration, level of customisation, and current production schedules. Please contact us with your requirements for an accurate delivery estimate.

Ready to Elevate Your Recycling?

Get a customised proposal, detailed pricing, and current lead times. Send us your project requirements using the form below – we’re here to help you find the perfect recycling solution.

[…] proces, der sikrer, at flaskerne løsnes og er klar til genbrug på få minutter. Integrer den i din genbrugslinje for at reducere omkostningerne, øge gennemløbet og strømline […]