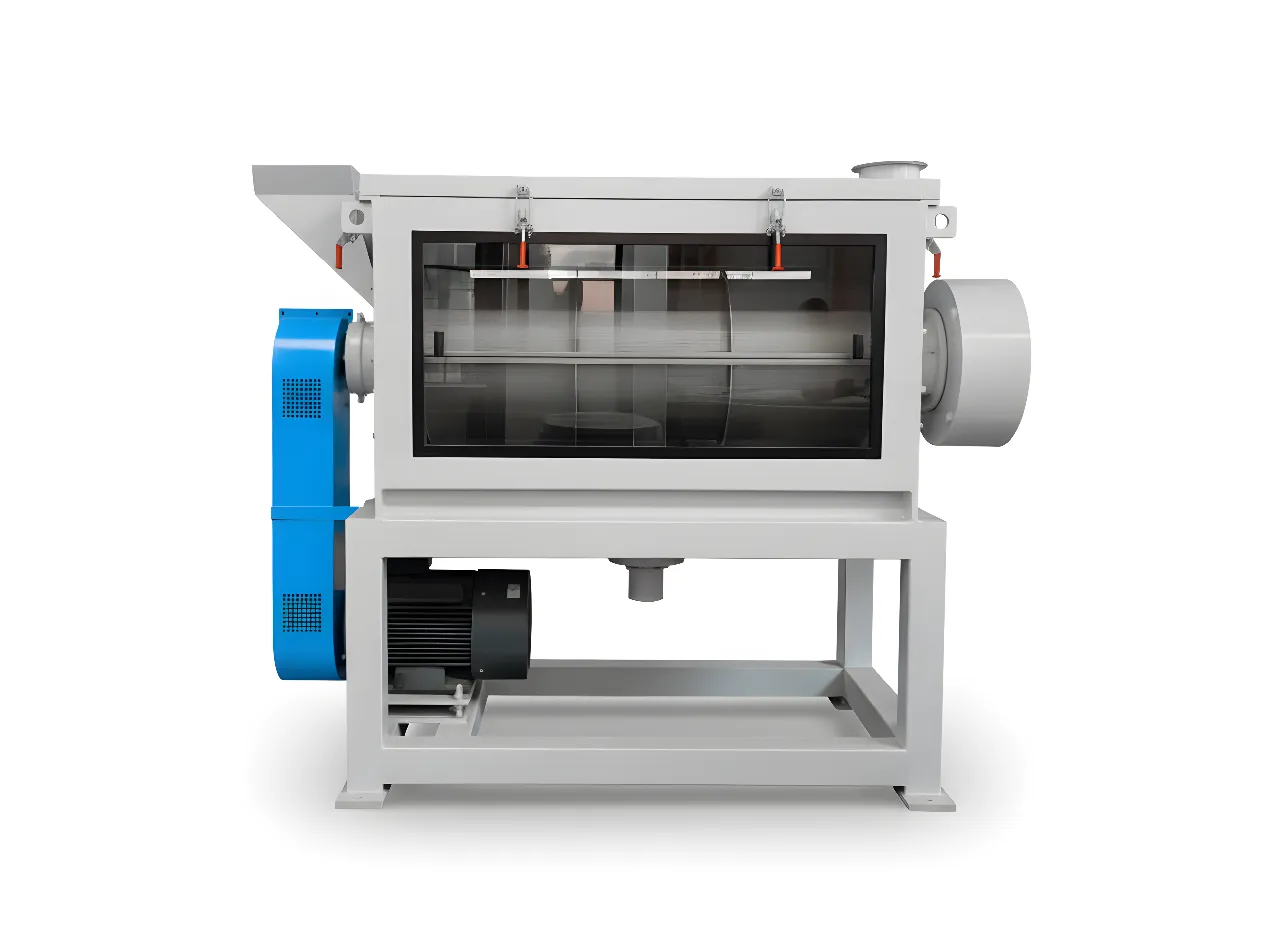

High-Speed Centrifugal Dewatering Machine

Eliminate the "wet flake" bottleneck and achieve moisture levels as low as 3-5% for your plastic film recycling line.

Požádejte o cenovou nabídkuStruggling With These Recycling Challenges?

Our High-Speed Centrifugal Dewatering Machine turns your biggest operational headaches into opportunities for higher profit and efficiency.

High Energy Costs

Are thermal dryers consuming a huge portion of your electricity budget just to evaporate water?

Our Solution: Mechanical Dewatering

Our machine uses centrifugal force—not heat—to instantly remove over 90% of water, drastically cutting the energy load and cost for any downstream thermal systems.

Poor Pellet Quality

Do wet flakes cause gas bubbles, foaming, and brittle, low-value pellets in your extruder?

Our Solution: Consistent Dryness

By delivering flakes with a stable moisture content below 5%, we ensure your extruder produces dense, smooth, high-quality granules that command a better price.

Frequent Downtime

Are you constantly stopping production to clear clogs and jams caused by lightweight films or dirty material?

Our Solution: "Non-Clog" Design

Our optimized rotor and paddle geometry create powerful airflow that keeps material moving, ensuring continuous, reliable operation even with challenging materials.

From Wet Flakes to Dry Material in 3 Steps

Our centrifugal dryer uses mechanical force to efficiently remove water from soft plastics, preparing them for high-quality pelletizing.

1. Feed Wet Material

Wet film flakes from the washing line (friction washer or sink-float tank) are fed into the machine's hopper.

2. High-Speed Dewatering

The rotor spins at up to 1,500 RPM, generating immense G-force that ejects water through a perforated screen.

3. Collect Dry Flakes

The dried plastic flakes (3-5% moisture) are discharged, ready for the thermal dryer, silo, or pelletizing extruder.

Ideal for Soft Plastic Washing Lines

Engineered for the rigorous demands of drying lightweight, high-surface-area plastics that standard dryers can't handle.

LDPE / LLDPE fólie

Efficiently dry post-consumer and post-industrial films to prevent hydrolysis and foaming in the extruder.

PP Woven Bags

Process and dewater shredded PP woven and non-woven materials for consistent, high-quality granule production.

Zemědělská mulčovací fólie

Our non-clog design handles sand-laden, abrasive films without blockages, ensuring continuous operation.

General Plastic Recycling

Serves as the primary, high-throughput drying stage in any soft plastic washing and recycling facility.

Engineering Superiority

Every component is designed for maximum drying efficiency, longevity, and minimal downtime.

Ultra-High Velocity Rotor

Heavy-duty rotor balanced for speeds up to 1,500 RPM generates extreme G-force, physically ejecting water far more effectively than low-speed tumbling.

Optimized Airflow Design

The angled paddles create a powerful air vortex that transports light flakes, prevents clogging, and strips surface moisture through evaporative separation.

Nerezová ocel SUS304

The screen basket, housing, and all water contact points are fabricated from high-grade SUS304 stainless steel, making it impervious to corrosion.

"Non-Clog" Paddle Geometry

Aggressive, stepped paddle design tipped with wear-resistant alloy steel ensures a continuous material flow, even with abrasive, sand-laden films.

Premium Bearing Houses

We use top-tier international bearings (SKF, NSK, FAG) in external, water-cooled blocks to prevent heat transfer and extend service life significantly.

Maintenance-Friendly Access

A segmented polygonal screen and pneumatic cover allow a single operator to swap screens or inspect blades in minutes, minimizing downtime.

Technické specifikace

Choose the model that fits your production needs. Detailed data on each machine's performance and construction.

| Model | Výkon motoru | Průměr hlavního hřídele | Rychlost otáčení | Kapacita (kg/h) |

|---|---|---|---|---|

| CFD-400 | 37 kW | 400 mm | 1400 ot./min | 400 – 800 |

| CFD-550 | 45 kW | 550 mm | 1200 ot./min | 600 – 1000 |

| CFD-750 | 55 kW | 750 mm | 1080 ot./min | 1200 – 2000 |

Galerie a živá ukázka

See our High-Speed Centrifugal Dewatering Machine in detail.

Získejte řešení a cenovou nabídku na míru

Stop paying to evaporate water in your extruder. Contact us for a quote on a high-speed dewatering solution that lowers energy costs and boosts your production yield.

Často kladené otázky

Centrifugal Dryer vs. Squeezer: Which is better?

They serve different primary roles. A Odstředivá sušička is best for high-throughput, energy-efficient bulk water removal (down to 3-5% moisture) with a lower initial investment. A Žmýkačka sušička is excellent for densifying material and achieving very low moisture (<1-2%), but has higher capital and energy costs. For ultimate efficiency, many lines use our centrifugal machine as the primary dryer before a smaller squeezer or thermal unit.

How is the machine integrated into an existing washing line?

Our dewatering machines are designed for "plug-and-play" integration. The ideal position is immediately after the final Friction Washer or Sink-Float Tank. The output can feed directly into a Hot Air Pipe Dryer, a silo, or the pelletizer's compactor.

What is maintenance like for this machine?

We prioritize operator-friendly design. The segmented screen allows for easy access and cleaning. A single operator can open the pneumatic cover to inspect or replace the wear-resistant blades in minutes. Bearings are housed externally for easy monitoring and lubrication.

Can it handle heavily contaminated agricultural film?

Yes. The machine is specifically designed for this challenge. The aggressive, "non-clog" paddle geometry and robust, wear-resistant blade tips ensure a continuous material flow without blockages from sand, dirt, or other contaminants.