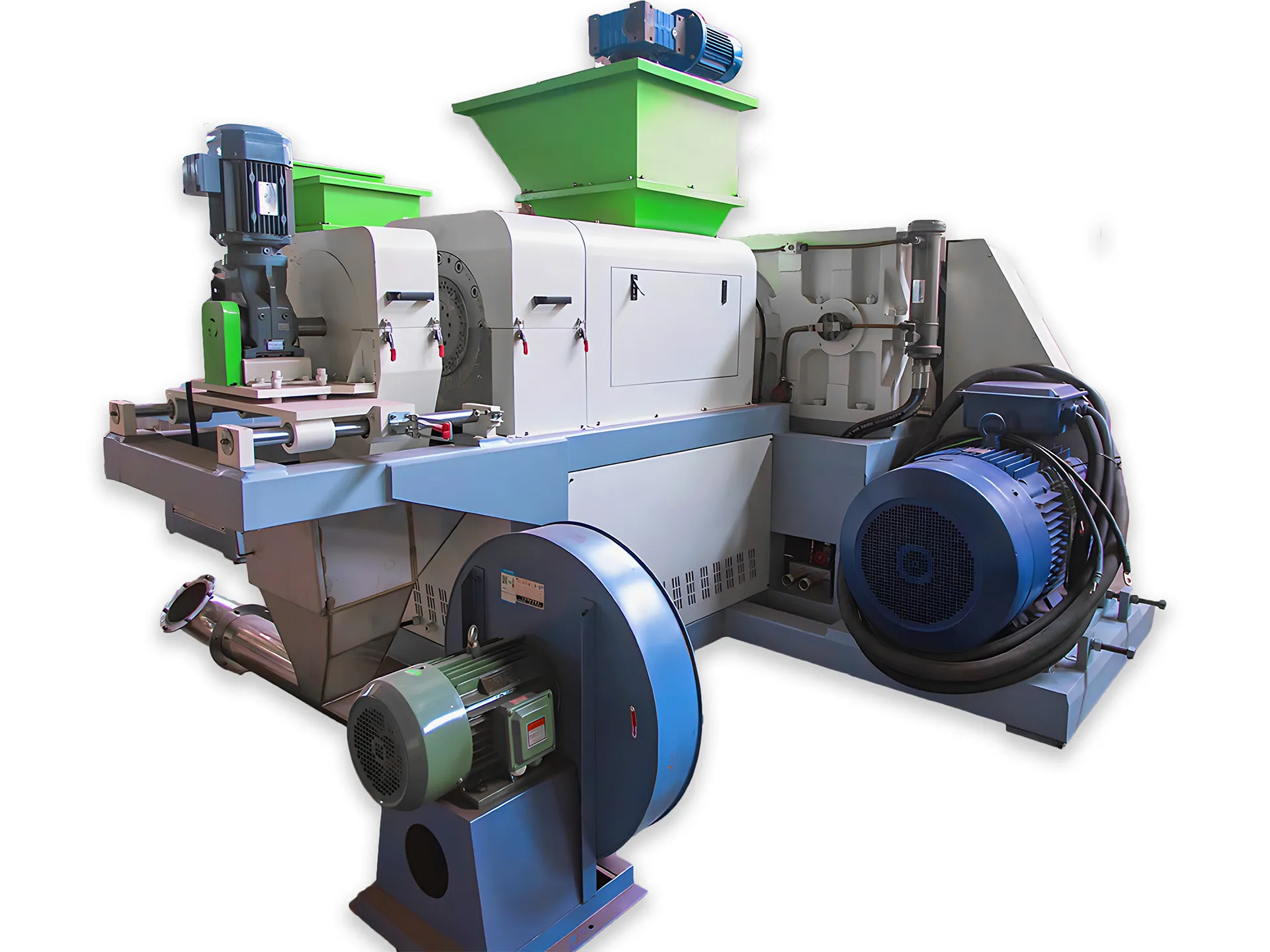

Industrial Plastic Recycling Drying Systems

Advanced moisture removal technology engineered for maximum efficiency, precision control, and superior recycled material quality.

High-Performance Industrial Drying

Our advanced drying systems are specifically engineered for plastic recycling facilities that demand maximum performance and throughput. With capacities ranging from 100 kg/h to 2,000 kg/h, these systems effectively remove moisture from flakes, regrind, and pellets to achieve industry-leading dryness levels.

Built with industrial-grade components and designed for 24/7 operation, our systems deliver consistent results even in the most demanding production environments, ensuring your recycled materials meet the highest quality standards.

Precise Moisture Control

Achieve moisture levels as low as 2% with our advanced drying technology, ensuring optimal material properties for high-quality end products.

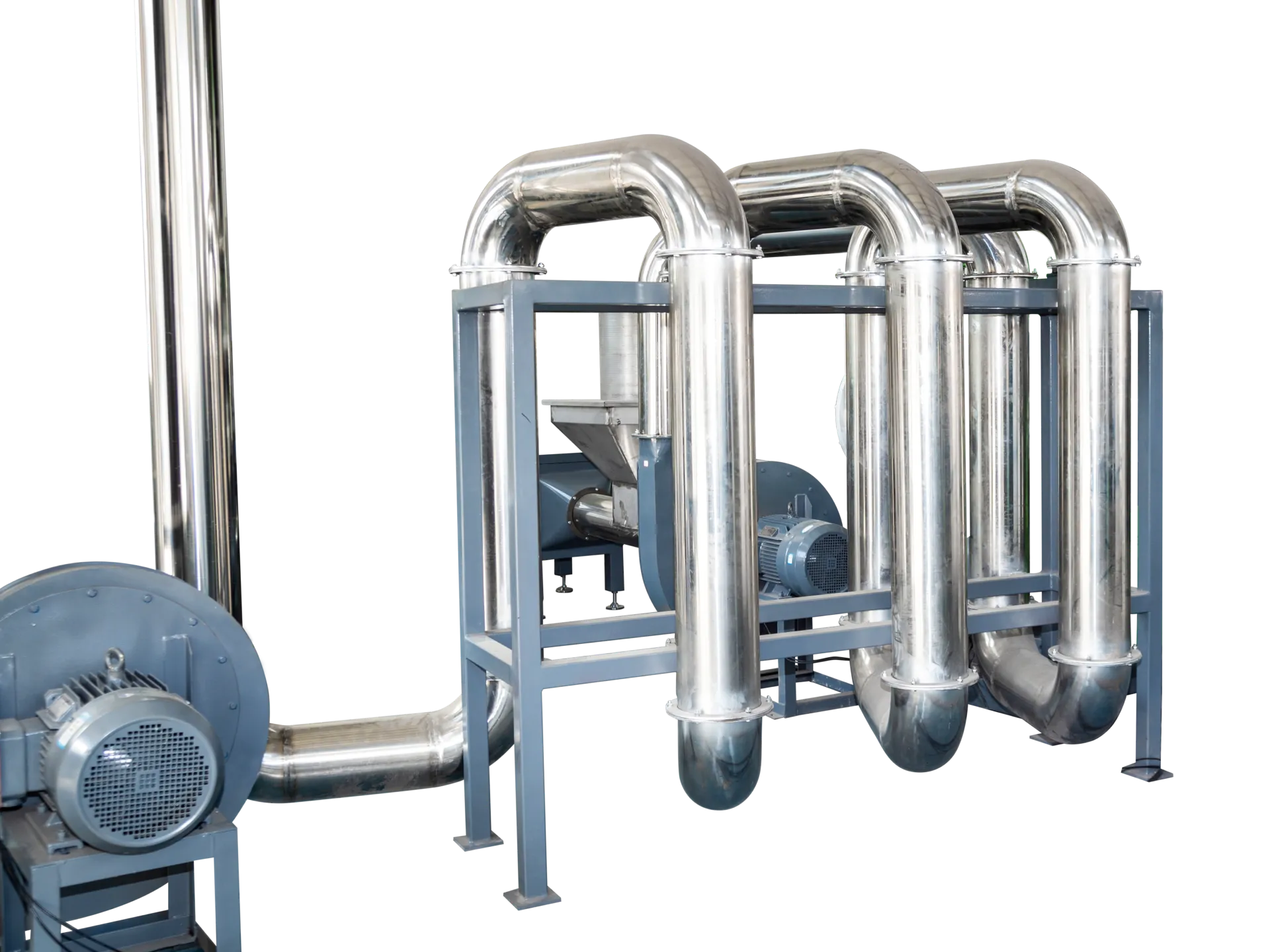

Energy-Efficient Processing

Our innovative heat recovery systems and insulation technology reduce energy consumption by up to 40% compared to conventional drying equipment.

Advanced Drying Technology

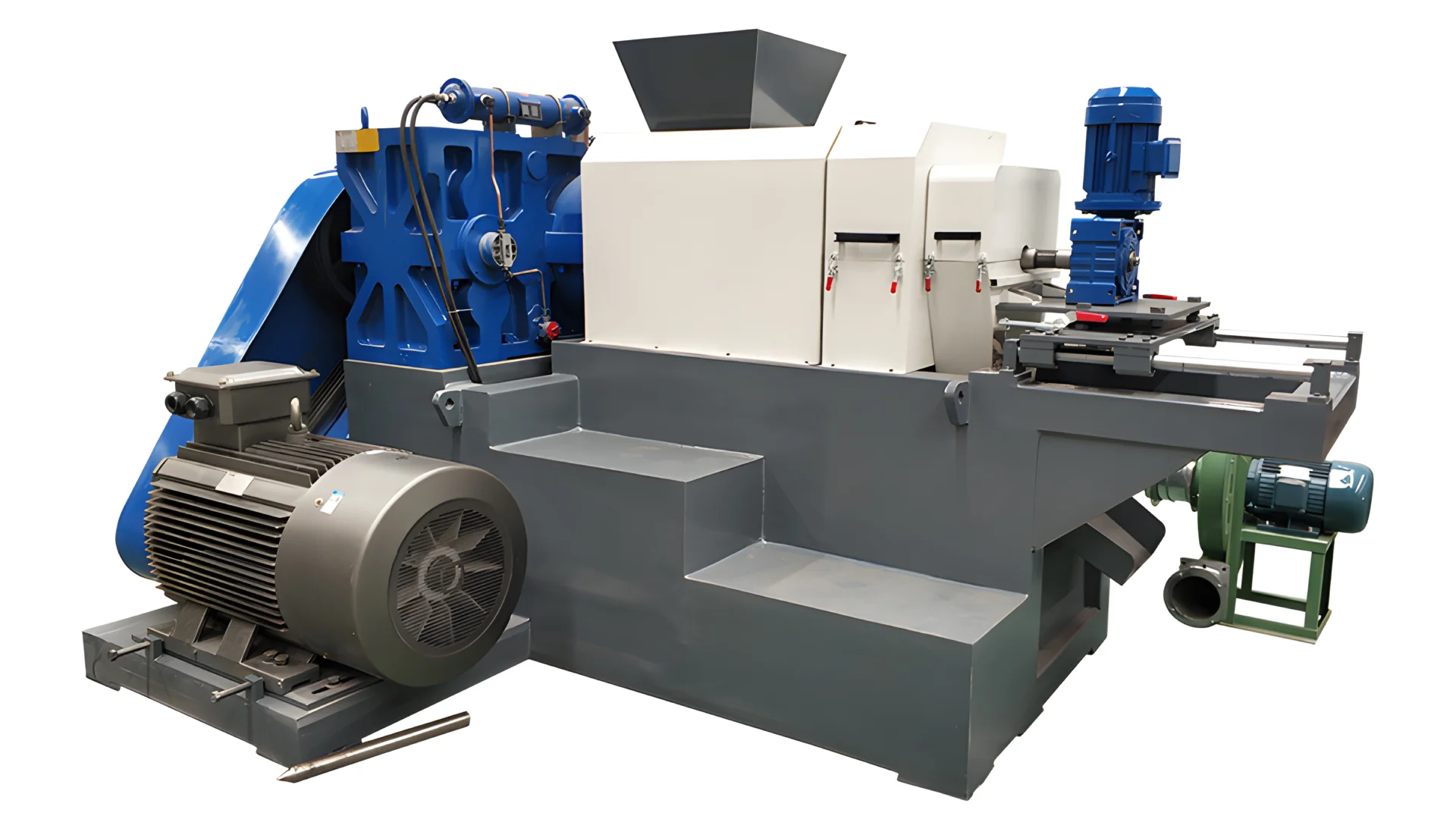

Our systems utilize multiple drying technologies optimized for different plastic types and contamination levels, ensuring maximum efficiency for your specific recycling operation.

Multi-Stage Processing

Combined mechanical and thermal drying for optimal moisture removal from PET, PE, PP, PS, and other polymers.

Precision Temperature Control

Adjustable temperature ranges from 60°C to 180°C with ±1°C accuracy for material-specific processing.

Multi-Polymer Compatibility

Efficiently process PET, PE, PP, PS, ABS, PA, PC, and other polymers with customizable settings for each material type and form factor.

معالجة عالية السعة

Available in multiple configurations with throughput capacities from 100 kg/h to 2,000+ kg/h to match your production requirements.

Measurable Business Benefits

Higher Material Value

Achieve premium pricing for recycled materials with moisture content as low as 2%.

انخفاض تكاليف التشغيل

Reduce energy consumption by up to 40% with our efficient heat recovery systems.

Increased Production Rates

Boost throughput by up to 30% compared to conventional drying systems.

Reduced Downstream Issues

Eliminate moisture-related processing problems in extrusion and molding operations.

نظام التحكم الذكي

PLC-based automation with 10" touchscreen HMI provides real-time monitoring, data logging, and remote access capabilities for optimal process control.

Comprehensive Service

Global technical support, preventive maintenance programs, and rapid-response service teams ensure maximum uptime and operational efficiency.

Optimize Your Recycling Process

Contact our engineering team for a personalized system recommendation based on your specific material requirements, production volume, and facility constraints.

Request Technical Consultation