Vertikální systém pro míchání plastů

Dokonalé řešení 2 v 1 pro efektivní míchání a sušení recyklovaných plastů. Maximalizujte propustnost a ušetřete cennou podlahovou plochu s jediným spolehlivým strojem.

Žádost o cenovou nabídkuProč si vybrat vertikální míchací sušičku Energycle?

Náš stroj je navržen pro výkon, spolehlivost a vynikající návratnost investic.

Vysoce účinné sušení

Pokročilý systém cirkulace horkého vzduchu zajišťuje rovnoměrné sušení a efektivně odstraňuje vlhkost, čímž zlepšuje kvalitu konečného produktu.

Homogenní míchání

Vertikální šnekový dopravník nepřetržitě zvedá a převaluje materiály, což zaručuje konzistentní směs plastů, masterbatchů nebo přísad.

Prostorově úsporný design

Kombinace míchání a sušení do jedné vertikální jednotky výrazně snižuje zastavěnou plochu zařízení ve vašem zařízení.

Odolné a nenáročné na údržbu

Vyrobeno z vysoce kvalitní nerezové oceli v kontaktních částech pro dlouhou životnost a snadné čištění, čímž se minimalizují prostoje.

Jednoduchý a efektivní princip fungování

Krok 1: Načítání

Plastové materiály (vločky, granule) se přivádějí do násypky ve spodní části.

Krok 2: Míchání a zvedání

Centrální šnekový dopravník zvedá materiál zespodu nahoru.

Krok 3: Sušení a dispergace

Horký vzduch je vháněn dovnitř, zatímco materiál kaskádovitě stéká dolů, čímž je zajištěn plný kontakt a odvod vlhkosti.

Krok 4: Propuštění

Po vysušení a smíchání se materiál vypustí bočním výpustem.

Klíčové vlastnosti a technické specifikace

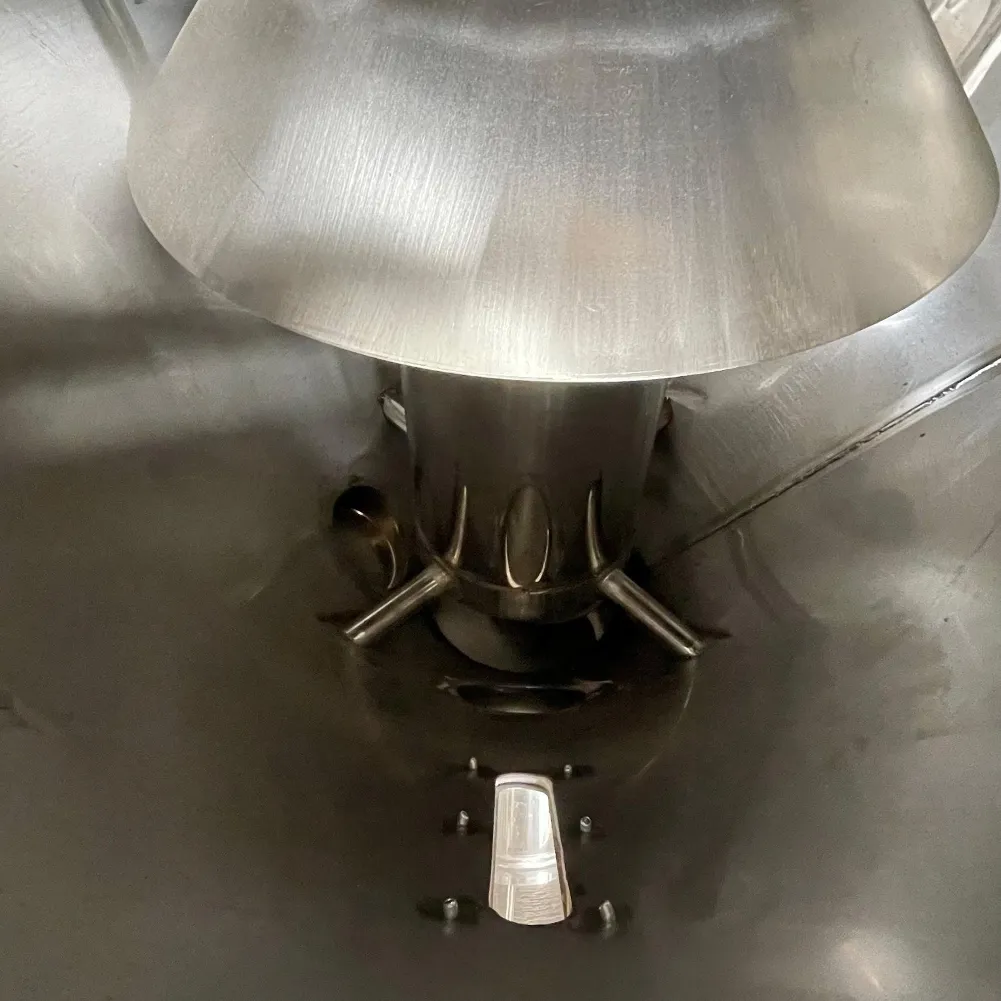

Šnek a komora z nerezové oceli

Kontaktní části vyrobené z nerezové oceli SUS304 zabraňují kontaminaci materiálu, odolávají korozi a usnadňují a zrychlují čištění.

Inteligentní regulace teploty

Vybaven PID regulátorem teploty pro přesné řízení tepla, zabraňuje přehřátí a degradaci materiálu a zároveň šetří energii.

Technické parametry

| Model | Kapacita (kg) | Výkon motoru (kW) | Topný výkon (kW) | Rozměry (D*Š*V mm) |

|---|---|---|---|---|

| ERM-VMD-500 | 500 | 4 | 9 | 1500*1500*2800 |

| ERM-VMD-1000 | 1000 | 5.5 | 18 | 1800*1800*3500 |

| ERM-VMD-2000 | 2000 | 7.5 | 24 | 2200*2200*4200 |

*Modely na míru k dispozici na vyžádání. Specifikace se mohou změnit bez předchozího upozornění.

Ideální aplikace

Sušení PET/HDPE/PP vloček

Míchání plastových granulí a pelet

Masterbatch a aditivní míchání

Předzpracování pro extruzní linky

Přehlídka vybavení

Získejte řešení a cenovou nabídku na míru

Naši technici jsou připraveni vám pomoci s konfigurací perfektního stroje pro vaše specifické potřeby. Vyplňte níže uvedený formulář a začněte.

Často kladené otázky

Jaké druhy plastů tento stroj zvládne?

Naše vertikální sušička plastů je vhodná pro širokou škálu tuhých a polotuhých plastů, včetně PET, HDPE, LDPE, PP, PS a ABS ve formě vloček, granulí nebo pelet.

Lze upravit teplotu sušení?

Ano, stroj je vybaven PID regulátorem teploty, který umožňuje nastavit a udržovat přesnou teplotu sušení, obvykle v rozmezí od 80 °C do 160 °C, v závislosti na požadavcích na materiál.

Jaká je typická dodací lhůta pro stroj?

Standardní modely mají obvykle dodací lhůtu 4–6 týdnů. U zakázkových konfigurací se dodací lhůta může lišit. Pro přesný dodací harmonogram na základě vaší konkrétní objednávky kontaktujte prosím náš obchodní tým.