Mokro sredstvo za uklanjanje naljepnica s plastičnih boca

Efficiently removes over 95% of labels from PET bottles during pre-washing, providing cleaner, higher-value material for your recycling process.

The Smarter Approach to PET Bottle Processing

Our cutting-edge machine is engineered to enhance the quality of your output and the efficiency of your entire operation.

High Separation Efficiency

Achieves over 95% label removal from intact bottles, significantly reducing paper and glue contamination in subsequent processes.

Integrirano predpranje

Water jets are employed to remove labels, simultaneously cleaning the bottle surface and eliminating dirt and residue.

Enhances Line Efficiency

Introducing cleaner, label-free bottles into your washing line boosts its overall capacity and final throughput.

Durable Alloy Knives

Specially designed, wear-resistant alloy knives guarantee long service life and consistent, high-performance label stripping.

Transform Contamination Issues into Purity Solutions

Conventional PET recycling methods often lead to problems that drain your time and resources. Our label remover addresses these issues at their root.

Problem: Contaminated Pellets

Granulating bottles with labels results in a mixed, low-quality output of PET and paper pellets that is challenging to sell at a premium.

Solution: Produce Pure PET

By removing labels initially, you produce exceptionally clean PET pellets, free from paper and glue, commanding a much higher market value.

Problem: Complex Separation

Separating shredded labels from PET pellets necessitates multiple downstream machines, escalating your investment, energy consumption, and factory space.

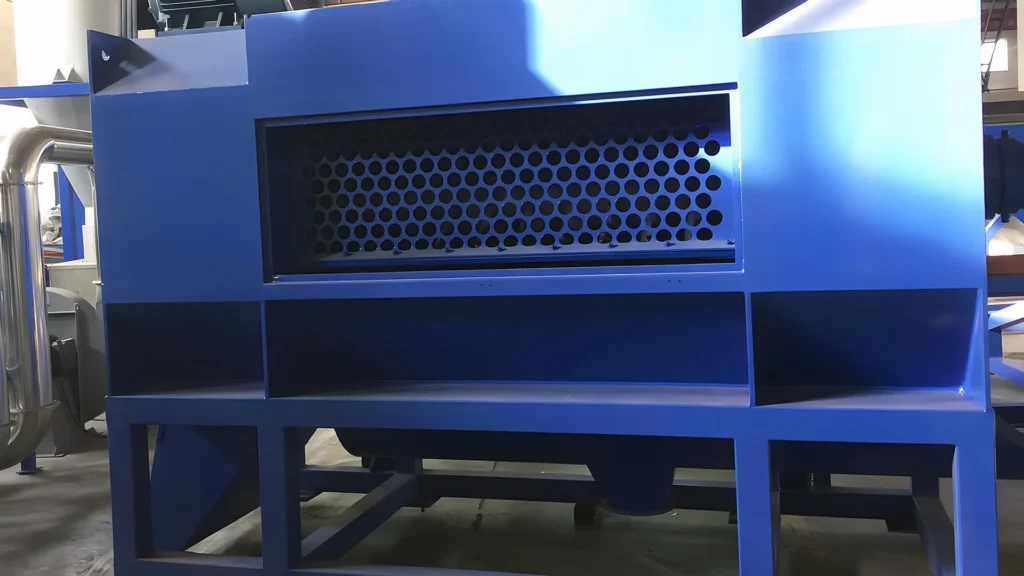

Izložba strojeva

Essential for Premium PET Recycling

This machine is a vital upgrade for any operation aiming to produce top-tier recycled PET materials.

Linije za pranje PET boca

The perfect initial step to pre-clean bottles and alleviate the strain on your primary washing tanks, friction washers, and dryers.

rPET Pellet Producers

Crucial for manufacturing pure, transparent, and high-value PET pellets for sale to manufacturers of new products.

Fiber & Sheet Production

Ensures the input material is free of paper and glue contaminants, which is crucial for high-quality polyester fiber and thermoforming sheet production.

Tehničke specifikacije

| Parametar | Vrijednost |

|---|---|

| Model | LR-W1500 |

| Kapacitet | 500 - 1,000 kg/hr |

| Label Removal Rate | > 95% |

| Snaga glavnog motora | 37 kW |

| Potrošnja vode | 1 - 2 m³/hr |

| Dimenzije (D*Š*V) | Approx. 4500 * 1800 * 2200 mm |

Često postavljana pitanja

What is the primary benefit of a *wet* label remover?

The main advantage is its dual functionality. It employs water to effectively strip labels while also pre-washing the bottles, removing surface dirt and contaminants in one go, thereby enhancing the efficiency and quality of your recycling line.

How are the labels separated from the bottles?

Durable alloy knives mounted on a high-speed rotor cut and tear the labels off the bottle bodies. Subsequently, powerful water jets spray the loose labels and water away into a separate collection chute, leaving the clean bottles to continue forward.

What maintenance is required for this machine?

The primary routine maintenance involves periodically inspecting the condition of the alloy knife blades. To maintain optimal performance, they will need to be sharpened or replaced as necessary. The machine's robust construction minimizes other maintenance requirements.

Improve Your PET Recycling Quality

Contact us to discover how our Wet Label Remover can enhance the purity of your pellets and the profitability of your operation. Obtain the latest prices and lead times today.

Komentari su zatvoreni.