Dokonalý drtič s jednou hřídelí pro odpad z extruderu

S naším robustním a spolehlivým drticím řešením snadno přeměníte odolný odpad z extrudérové hlavy na cenný, znovu použitelný materiál.

Žádost o cenovou nabídkuNavrženo pro výkon a odolnost

Robustní pohonná jednotka

Je vybaven reduktorem řady H s vysokým točivým momentem a pevnou, jednodílnou hlavní hřídelí, která zajišťuje konzistentní dodávku výkonu pro drcení i těch nejtvrdších materiálů.

Cenově výhodné čepele

Naše unikátní pohyblivé nože se čtyřmi úhly lze otáčet a používat tak novou ostrou hranu, což výrazně prodlužuje jejich životnost a snižuje náklady na údržbu.

Inteligentní ochrana

Pokročilý řídicí systém PLC obsahuje automatický mechanismus pro návrat do stavu přetížení, který zabraňuje poškození a zaručuje dlouhodobou provozní spolehlivost.

Z odpadu na surovinu ve čtyřech jednoduchých krocích

Podávání materiálu

Hydraulický píst zajišťuje stabilní a kontrolovanou rychlost posuvu, čímž rovnoměrně posouvá odpad z extruderu do drticí komory.

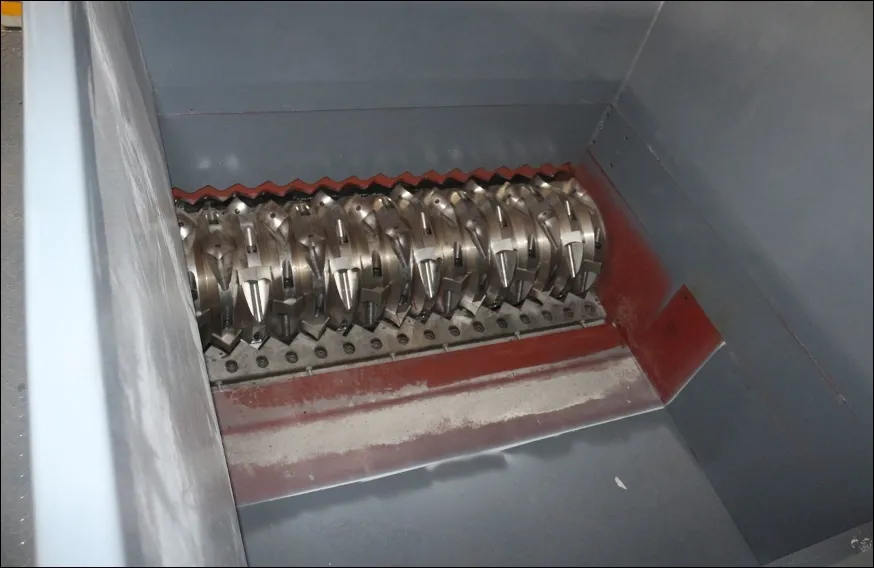

Efektivní drcení

Rotační nože z vysokopevnostní legované oceli pracují proti pevným nožům a stříhají materiál na menší, rovnoměrné kusy.

Řízení PLC

Systém monitoruje zatížení motoru. Pokud je detekováno přetížení, hřídel se automaticky otočí zpět, aby se uvolnilo zablokování, a poté bude pokračovat.

Výstup materiálu

Drcený materiál propadá přes síto (volitelné), což zajišťuje konzistentní velikost částic a je připraven k další fázi recyklace.

Podívejte se na Shreddera v akci

Přesvědčte se sami, jak náš jednohřídelový drtič efektivně zpracovává tvrdé průmyslové plasty. Toto video demonstruje výkon stroje, plynulý chod a kvalitu konečného drceného produktu.

Podrobné vlastnosti a technické specifikace

Hlavní shromáždění

Jádro stroje je postaveno na robustním rámu s masivní, CNC obráběnou rotační hřídelí. To je doplněno externím ložiskovým sedlem rámu od renomované domácí značky (Wafangdian) pro větší stabilitu a snadnou údržbu.

Napájení a ovládání

Drtič je poháněn výkonným motorem o výkonu 22 kW a reduktorem Permanent Teeth řady H a dosahuje stabilního výkonu 81 ot./min. Celý provoz je řízen systémem Delta PLC s vysoce kvalitními elektrickými komponenty Siemens a Schneider pro bezkonkurenční spolehlivost.

Hydraulický systém

Hydraulický systém o výkonu 3 kW pohání vozík s materiálem a dosahuje tlaku až 21 MPa. To zajišťuje stabilní a nastavitelnou rychlost podávání. Systém je udržován na optimální teplotě účinným mechanismem chlazení vzduchem.

| Položka | Parametr | Popis |

|---|---|---|

| Model | RTM-SD2360 | Jednohřídelový drtič |

| Výstup | 200–300 kg/h | Záleží na typu materiálu a velikosti obrazovky. |

| Drticí komora | 550 mm x 580 mm | Efektivní pracovní prostor pro zpracování materiálu. |

| Systém řezačky | 30 pohyblivých, 1 pevná čepel | Čepele z legované oceli SKD-11 (40x40 mm) na hřídeli o průměru 230 mm. |

| Výkon hlavního motoru | 22 kW | Spolehlivá tuzemská značka motorů. |

| Hydraulický výkon | 3 kW | Pohání píst pro podávání materiálu. |

Galerie strojů

Získejte řešení a cenovou nabídku na míru

Naši odborníci jsou připraveni vám pomoci s konfigurací perfektního drtiče dle vašich specifických potřeb. Kontaktujte nás ještě dnes a získejte nejnovější ceny a dodací lhůty.