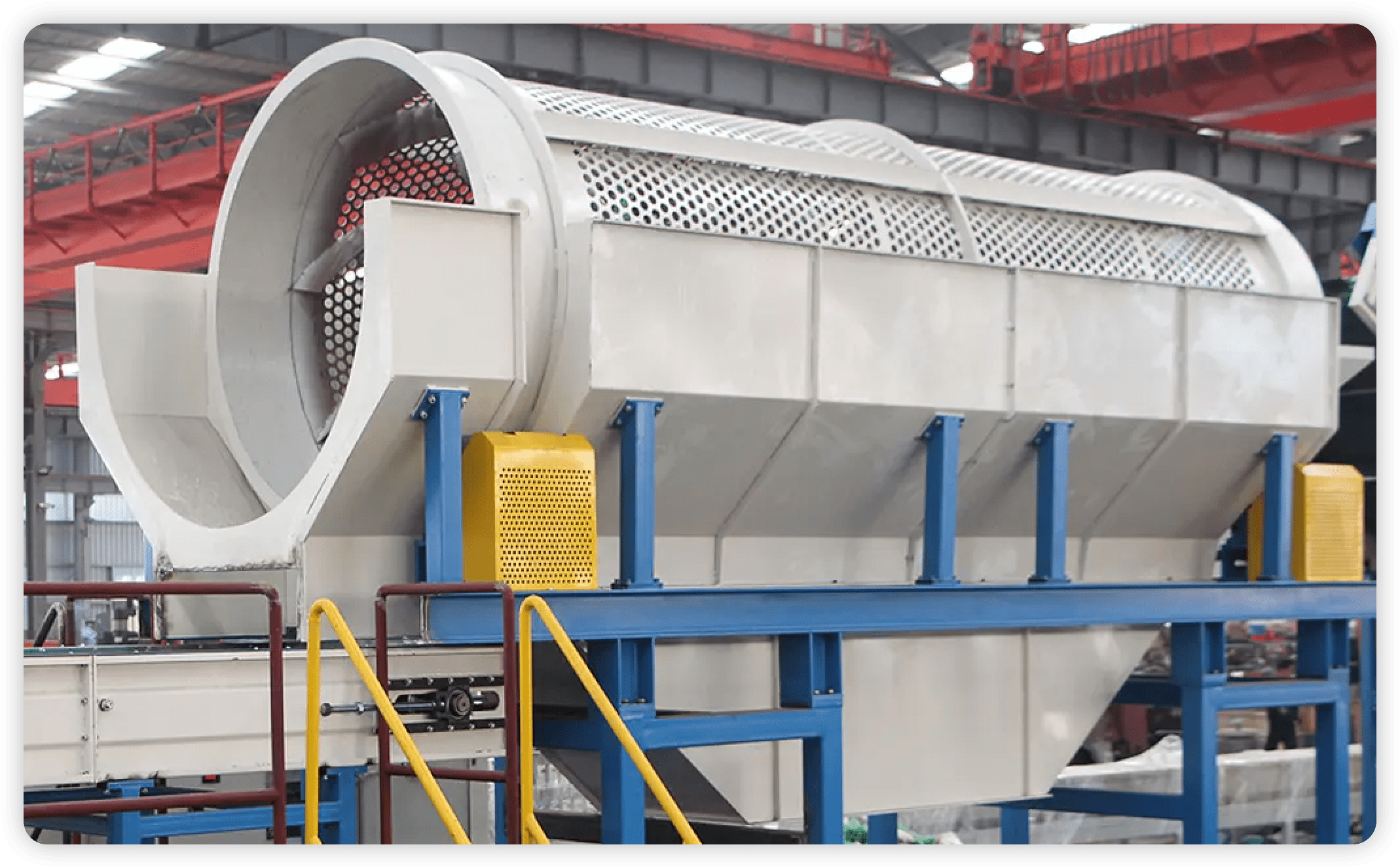

Jeste li se ikada pitali kako se velike količine materijala učinkovito sortiraju? Upoznajte trommel screen, često nazivan rotacijski zaslonOvaj pametni komad strojarstva je snažna snaga u industriji prerade minerala i krutog otpada, posebno dizajniran za odvajanje materijala na temelju njihove veličine. Zamislite veliki, perforirani cilindrični bubanj, obično blago nagnut – to je srce bubnja, koji neumorno radi na sortiranju materijala s impresivnom lakoćom.

Kako Trommel sita rade svoju magiju?

Prekrasno je jednostavno, a opet vrlo učinkovito! Kako se bubanj okreće, materijali unutra se prevrću i skupljaju. Manje čestice prolaze kroz perforacije (rupe) sita, padaju ispod i skupljaju se. U međuvremenu, veći predmeti ostaju unutar bubnja i putuju njegovom dužinom dok ne izađu na drugom kraju. Ovaj jednostavan proces čini trommel sita nevjerojatno svestranim za sortiranje svega, od tla i bogatog komposta do komunalnog krutog otpada i vrijednih minerala.

Upoznavanje ključnih komponenti

- Bubanj: Zvijezda predstave! Ovaj rotirajući, perforirani cilindar obavlja stvarni posao prosijavanja.

- Motor i mjenjač: Snaga koja osigurava rotacijski mišić potreban za glatko i dosljedno okretanje bubnja.

- Struktura podrške: Čvrsti okvir koji sigurno drži bubanj, osigurava stabilnost i održava ispravan radni kut.

- Ulazni i izlazni kanali: Jasno definirane ulazne i izlazne točke koje učinkovito usmjeravaju materijale u i iz bubnja.

- Zaslonske ploče/mreža: Ugrađuju se unutar bubnja. Dolaze u različitim veličinama rupa i materijalima, prilagođeni kako bi savršeno odgovarali specifičnom poslu odvajanja.

Gdje Trommel sita čine razliku?

- Obrada otpada: Neophodni pomagači u postrojenjima za komunalni otpad (MSW), učinkovito odvajajući reciklabilne materijale, organske tvari i ostale komponente otpada.

- Prerada minerala: Široko se koristi u rudarskoj industriji za klasifikaciju ruda, tla i agregata na temelju veličine, što je ključno za vađenje vrijednih resursa.

- Poljoprivreda i uređenje okoliša: Savršeno za prosijavanje komposta, površinskog sloja zemlje i drvne sječke, stvarajući visokokvalitetne proizvode za poljoprivredne, vrtlarske i krajobrazne projekte.

- Industrija recikliranja: Ključni igrači u sortirnim postrojenjima, odvajajući materijale poput plastike, stakla i metala od ostalog otpada radi poboljšanja stope recikliranja i čistoće.

Zašto odabrati Trommel sito? Prednosti

- Izvanredna učinkovitost: Sposoban za brzo i učinkovito rukovanje i odvajanje velikih količina materijala.

- Nevjerojatna svestranost: Lako se prilagođava različitim materijalima (mokrim ili suhim) i raznim industrijskim primjenama.

- Niske potrebe za održavanjem: Njihov robustan i relativno jednostavan dizajn rezultira nižim operativnim troškovima i manjim zastojima.

- Ekološki prihvatljivo: Poboljšanjem sortiranja za recikliranje i kompostiranje, oni igraju ključnu ulogu u smanjenju otpada na odlagalištima i promicanju održivih praksi.

Zamotavanje

Ukratko, bubnjevi sita su pravi radni konji! Ovi svestrani i visoko učinkoviti strojevi nezamjenjivi su alati u više industrija za učinkovito odvajanje materijala. Njihov jednostavan rad, u kombinaciji sa značajnim prednostima poput visokog protoka i niskog održavanja, čini ih temeljem modernog gospodarenja otpadom, recikliranja, rudarstva i poljoprivrednih operacija. Odabir bubnjevog sita nije samo operativna nadogradnja; to je korak prema većoj učinkovitosti i ekološkoj odgovornosti.

ZAINTERESIRANI? RAZGOVARAJMO!

Spremni ste povećati učinkovitost svog poslovanja? Pošaljite nam poruku putem donjeg obrasca kako biste dobili najnovije cijene i razgovarali o rokovima isporuke. Tu smo da vam pomognemo!