Introduzione

La scelta del sistema di pellettizzazione più adatto per la vostra linea di produzione di PET è una decisione cruciale che può avere un impatto significativo sull'efficienza operativa, sulla qualità del prodotto e sui costi a lungo termine. Tra i metodi più utilizzati vi sono: pellettizzazione ad anello d'acqua E pellettizzazione a filamenti raffreddata ad acquaOgni sistema ha i suoi vantaggi ed è adatto a diversi obiettivi di produzione e vincoli della struttura.

A Macchina Energycle, siamo specializzati nell'aiutare i produttori negli Stati Uniti e in Europa a ottimizzare le loro linee di riciclaggio e lavorazione dei polimeri. Se state valutando sistemi progettati per scaglie di PET, visitate il nostro Pellettizzatore a vite singola per scaglie di plastica PET pagina per saperne di più sulle soluzioni monovite ad alta efficienza.

Questa guida approfondita ti guiderà attraverso un confronto equilibrato di entrambe le tecnologie di pellettizzazione, aiutandoti a determinare la soluzione più adatta alle tue esigenze specifiche.

Comprensione delle basi della pellettizzazione del PET

La pellettizzazione del PET (polietilene tereftalato) è un processo a valle della linea di riciclo della plastica o della produzione di polimeri vergini, in cui il PET fuso viene convertito in pellet solidi. Questi pellet sono più facili da maneggiare, trasportare e riutilizzare nei processi produttivi.

I due sistemi dominanti sono:

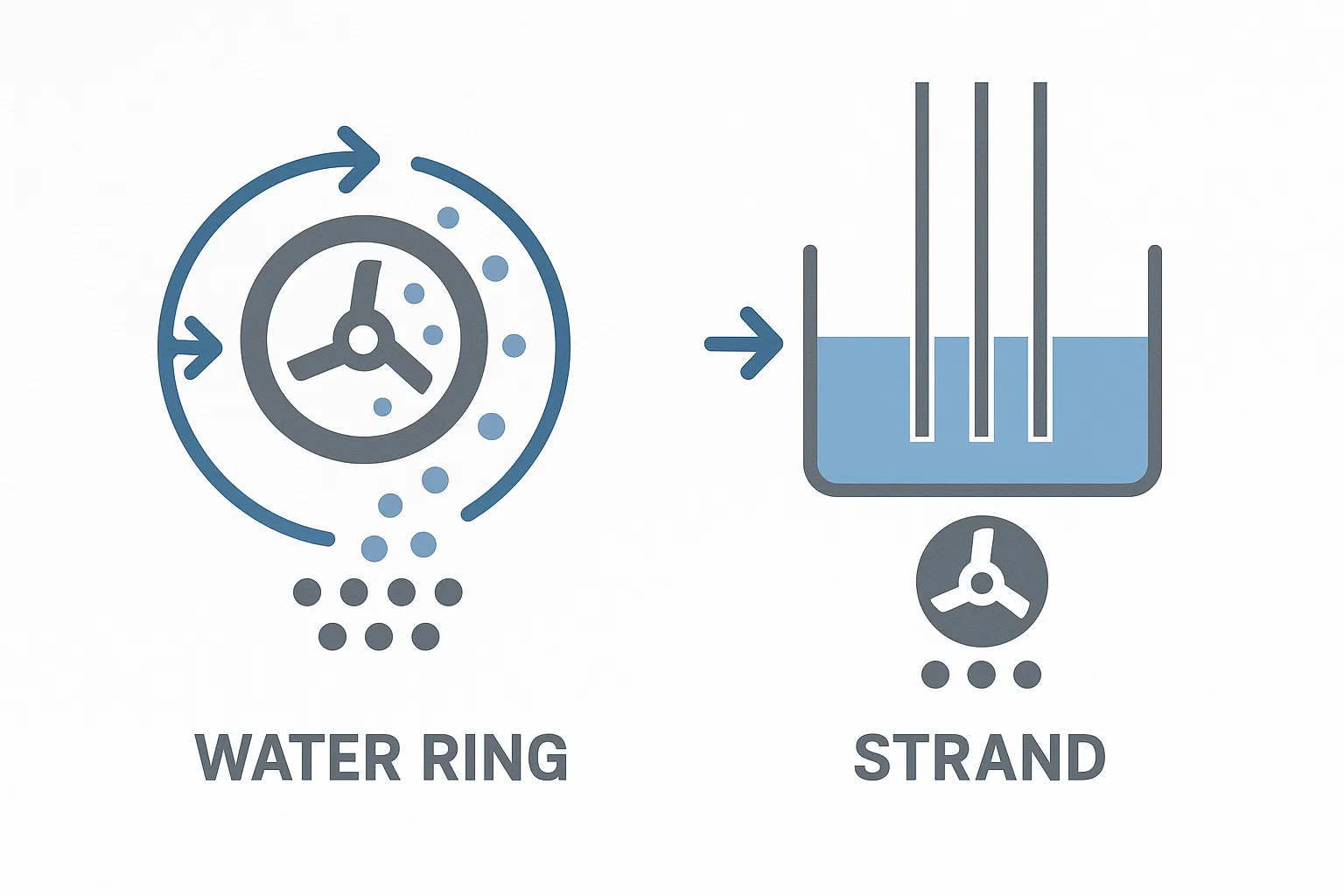

- Pellettizzazione ad anello d'acqua: Il PET fuso viene estruso attraverso una filiera e tagliato immediatamente in pellet da lame rotanti. I pellet vengono quindi raffreddati in un anello di acqua circolante.

- Pellettizzazione a filamenti raffreddata ad acqua:Il PET fuso viene estruso in fili continui, raffreddato in un bagno d'acqua e poi tagliato in pellet.

Per i fiocchi di bottiglie in PET, Macchina Energycle offre anche sistemi di pellettizzazione specializzati Progettato per una produzione stabile e una qualità costante dei pellet.

Ingombro e requisiti di spazio

Pellettizzazione ad anello d'acqua

I sistemi ad anello d'acqua sono compatti e altamente integrati. Occupano meno spazio, il che li rende ideali per le strutture in cui lo spazio è limitato. Tutti i componenti principali, inclusi il cutter, l'anello d'acqua e l'essiccatore, sono generalmente assemblati come un'unica unità.

Pellettizzazione a filamenti raffreddata ad acqua

I sistemi a trefoli richiedono maggiore spazio a causa delle vasche di raffreddamento dell'acqua e della disposizione dei trefoli. Questa configurazione può rappresentare una limitazione per gli stabilimenti più piccoli o per gli impianti di ammodernamento. Tuttavia, può offrire maggiore flessibilità nella gestione di diverse viscosità dei materiali.

Macchina Energycle consiglia di valutare la disposizione del tuo impianto per capire quale sistema si adatta meglio al tuo spazio operativo.

Automazione e semplicità d'uso

Pellettizzazione ad anello d'acqua

I sistemi ad anello d'acqua sono generalmente più automatizzati e richiedono meno interventi da parte dell'operatore. La pressione della lama è spesso autoregolante e l'essiccazione dei pellet è integrata, riducendo la necessità di interventi manuali.

Pellettizzazione a filamenti raffreddata ad acqua

I sistemi di pellettizzazione a filamenti richiedono più manodopera. Gli operatori devono garantire il corretto allineamento dei filamenti e un flusso d'acqua costante. L'avvio e lo spegnimento richiedono maggiore attenzione e competenza.

Per i produttori che mirano a ridurre i costi di manodopera e migliorare la coerenza, Macchina Energycle suggerisce di prendere in considerazione la pellettizzazione ad anello d'acqua per i suoi vantaggi in termini di automazione.

Forma e qualità del pellet

Pellettizzazione ad anello d'acqua

Produce pellet arrotondati e uniformi con una finitura lucida. Sono particolarmente indicati per applicazioni di fascia alta in cui l'estetica e la scorrevolezza del pellet sono fondamentali.

Pellettizzazione a filamenti raffreddata ad acqua

I pellet sono tipicamente cilindrici con estremità leggermente irregolari. Pur essendo ancora funzionali per la maggior parte degli usi a valle, potrebbero non soddisfare gli standard estetici o di lavorazione più elevati.

Se l'uniformità e l'aspetto del pellet sono fondamentali per la tua applicazione, Macchina Energycle consiglia sistemi ad anello d'acqua.

Tabella comparativa riassuntiva

| Caratteristica | Pellettizzazione ad anello d'acqua | Pellettizzazione a filamenti raffreddata ad acqua |

|---|---|---|

| Orma | Compatto | È necessario più spazio |

| Automazione | Alto | Da medio a basso |

| Forma a pellet | Rotondo, uniforme | Cilindrico, variabile |

| Manutenzione | Moderare | Minore rischio di usura |

| Costo iniziale | Più alto | Inferiore |

| Costo operativo | Inferiore a lungo termine | Costi di manodopera più elevati |

| Capacità di produzione | Alto | Medio |

| Flessibilità dei materiali | Medio | Alto |

Domande frequenti

D1: Posso installare un pelletizzatore ad anello liquido sulla mia attuale linea PET?

Sì, molti di Macchina EnergycleI modelli sono progettati per essere adattati, ma è necessario valutare i parametri di layout ed estrusione.

D2: Quale pelletizzatore è più adatto al PET riciclato?

La pellettizzazione ad anello d'acqua è spesso migliore per il PET riciclato, grazie alla maggiore produttività e alla migliore integrazione dell'essiccazione.

D3: Sono disponibili sistemi ibridi?

Alcuni sistemi offrono opzioni modulari che combinano le caratteristiche di entrambi i tipi di pellettizzazione. Macchina Energycle può consigliarti soluzioni personalizzate.

D4: Qual è il tipico periodo di ammortamento per l'aggiornamento a un sistema ad anello d'acqua?

A seconda della produzione e dei costi di manodopera, il tempo di recupero dell'investimento può variare da 1 a 3 anni.

Fai la scelta giusta per la tua linea di produzione

La scelta del giusto sistema di pellettizzazione può plasmare il futuro della tua linea di produzione PET. Lascia che Macchina Energycle aiutarti a fare un investimento consapevole e a prova di futuro.

Visita il nostro Pellettizzatore a vite singola per scaglie di plastica PET pagina o contattaci oggi stesso per discutere delle tue esigenze.

Richiedi un preventivo personalizzato