Hogyan maximalizálja a testreszabás a műanyag-újrahasznosítás hatékonyságát?

A műanyag-újrahasznosító gépek testreszabása kulcsfontosságú az újrahasznosítási műveletek hatékonyságának növelése érdekében. Íme, hogyan alakíthatja át a testreszabás az újrahasznosítási folyamatot:

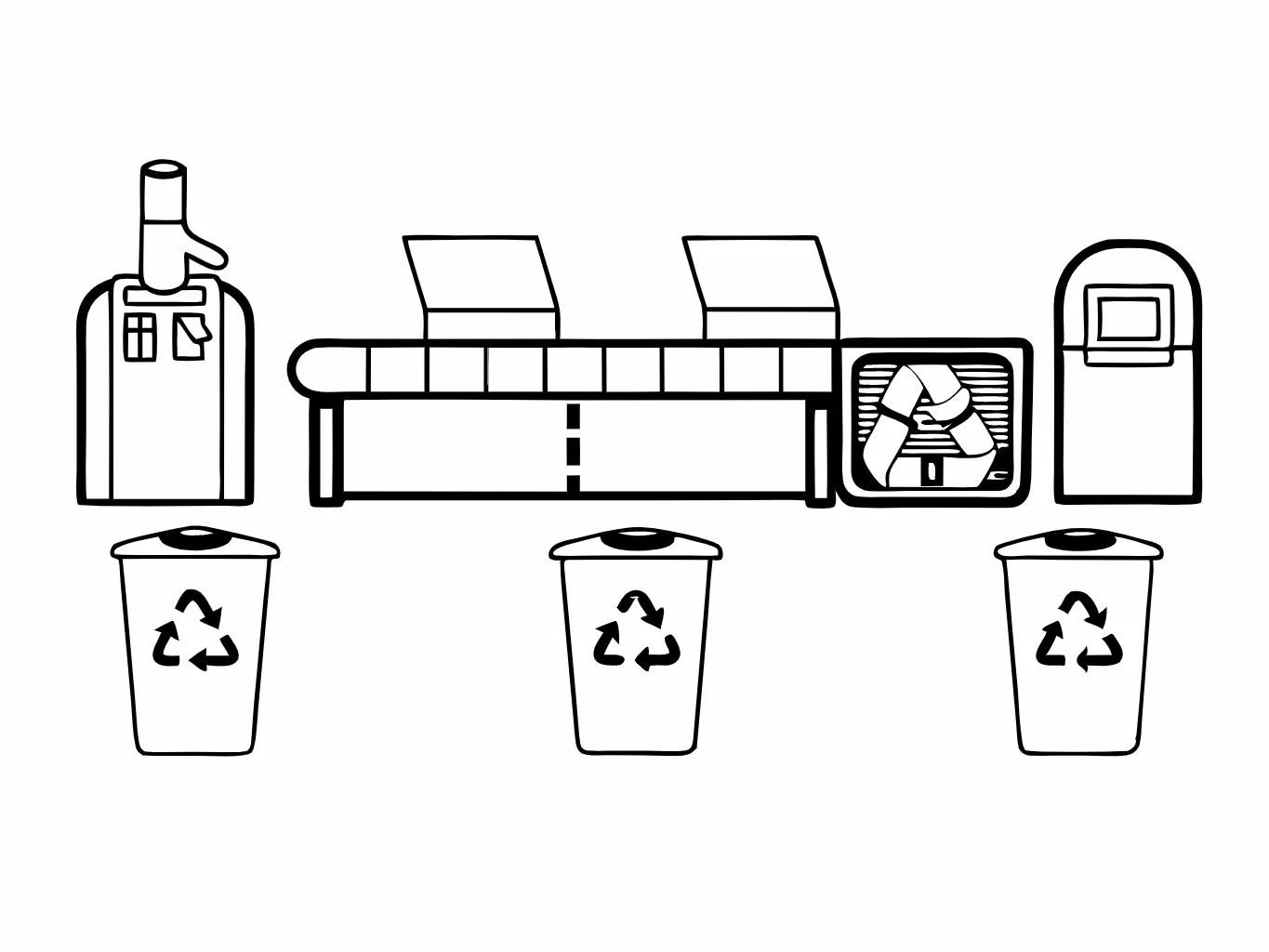

- Energia- és helytakarékosságAz egyedi elrendezések lehetővé teszik a hely optimális kihasználását az üzemben, biztosítva, hogy a gépek az energiafelhasználás minimalizálása és az áteresztőképesség maximalizálása érdekében legyenek elhelyezve. Például a gépek L, I vagy U alakban is kialakíthatók, hogy illeszkedjenek a meglévő gyári elrendezésekhez, csökkentve a jelentős módosítások vagy bővítések szükségességét. Ez a térbeli hatékonyság közvetlenül energiamegtakarításhoz vezet, mivel a gépek optimális kapacitásukhoz közelebb működhetnek a rossz elrendezés-tervezéssel járó energiapazarlás nélkül.

- Speciális műanyagtípusokhoz igazítvaNem minden műanyag egyforma; a különböző típusok eltérő feldolgozási módszereket igényelnek. A testreszabás lehetővé teszi olyan speciális eszközök, mint az aprítók, extruderek vagy pelletizálók integrálását, amelyek a leginkább megfelelnek az Ön által általában kezelt műanyagtípusoknak, legyen szó PET-ről, HDPE-ről, LDPE-ről vagy másról. Ez a specifikusság magasabb visszanyerési arányt és kevesebb szennyeződést biztosít, ami elengedhetetlen a kiváló minőségű újrahasznosított anyagok előállításához.

- Fokozott rugalmasság és egyszerűsített működésAz egyedi gépek segítségével könnyebben alkalmazkodhat a változó bejövő hulladékáramokhoz. Az olyan funkciók, mint az állítható vágópengék vagy a moduláris alkatrészek, azt jelentik, hogy a hulladékáram változásával a gépek is változhatnak, anélkül, hogy teljes felújításra lenne szükség. Ez az alkalmazkodóképesség nemcsak leegyszerűsíti a műveleteket, hanem csökkenti az állásidőt is, növelve az általános termelékenységet.

- Az újrahasznosított műanyag jobb minőségeA testreszabás magában foglalhat nagy pontosságú vezérlőrendszereket vagy speciális szűrőrendszereket, amelyek biztosítják a kimenet tisztaságát és minőségét. Az újrahasznosított pelletek vagy pelyhek minőségére összpontosítva olyan iparágakat szolgálhat ki, amelyek kiváló minőségű újrahasznosított anyagokat igényelnek, ezáltal bővítve piacát.

- A körforgásos gazdaság támogatásaAzzal, hogy a hatékonyság révén gazdaságilag életképesebbé teszi az újrahasznosítást, a testreszabás közvetlenül hozzájárul a körforgásos gazdasághoz. Több vállalkozást ösztönöz az újrahasznosításra, csökkentve a hulladéklerakókban keletkező hulladékot és a szűz műanyagok iránti keresletet.

Egyedi elrendezések tervezése műanyag újrahasznosító gépekhez

Az újrahasznosító létesítmény elrendezésének mérlegelésekor:

- Értékelje a terétÉrtékelje létesítménye méretét, alakját és korlátait. Az olyan gyártók, mint a Rumtoo, egyedi elrendezései szinte bármilyen helyiséghez illeszkedhetnek, biztosítva, hogy minden gép optimális áramlást és minimális energiafogyasztást biztosítson.

- Válassza ki a megfelelő formát: A munkafolyamatodtól függően válassz L, I vagy U alakú elrendezést. Az L alakú elrendezés ideális lehet kisebb terekhez, ahol az anyagoknak előre-hátra kell mozogniuk, míg az U alakú elrendezés nagyobb területeken biztosíthatja a folyamatos áramlást.

- Integrálja a speciális igényeketAkár egy vágóprésről van szó a terjedelmesebb műanyagokhoz, akár egy garatos adagolóról az állandó bemenet érdekében, a speciális géptípusok integrálása az elrendezésbe drasztikusan javíthatja a hatékonyságot.

- JövőbiztosAhogy a működése növekszik vagy változik, a rugalmas elrendezésű gépek biztosítják, hogy azok az üzleti igényekkel együtt fejlődhessenek, elkerülve ezzel az új gépekre fordított jelentős tőkekiadásokat.

Miért érdemes a testreszabást választani?

- Gazdasági előnyökAz egyedi gépek gyorsabb megtérülést eredményezhetnek a befektetés terén, mivel hatékonyak és alkalmazkodóképesek az Ön konkrét hulladékprofiljához.

- Környezeti hatásAz újrahasznosítási folyamat optimalizálásával csökkentheti a hulladékot és az energiafogyasztást, ezáltal csökkentve a szénlábnyomát.

- Piaci versenyképességA kiváló minőségű újrahasznosított termékek kínálata új piaci szegmenseket nyithat meg a csomagolástól a gyártásig, ahol az újrahasznosított tartalmat egyre inkább értékelik.

Következtetés

Testreszabása műanyag újrahasznosító gép Az elrendezés nem csak a berendezések elhelyezéséről szól a térben; a műanyaghulladék kezelésének újragondolásáról is, hogy a folyamat minden részét hatékonyabbá tegyük. Azzal, hogy a személyre szabás módjára, a figyelembe veendő szempontokra és a fontosságukra összpontosítunk, a vállalkozások jelentősen javíthatják újrahasznosítási műveleteiket. Részletes információkért vagy az Ön egyedi igényeinek megbeszéléséhez forduljon hozzánk bizalommal. lépjen kapcsolatba velünk a gép elrendezésének testreszabásával kapcsolatos további részletekért.

Ez a megközelítés nemcsak a fenntarthatósági célokkal van összhangban, hanem vállalkozását is vezetővé teszi a hatékony, kiváló minőségű műanyag-újrahasznosítás terén.