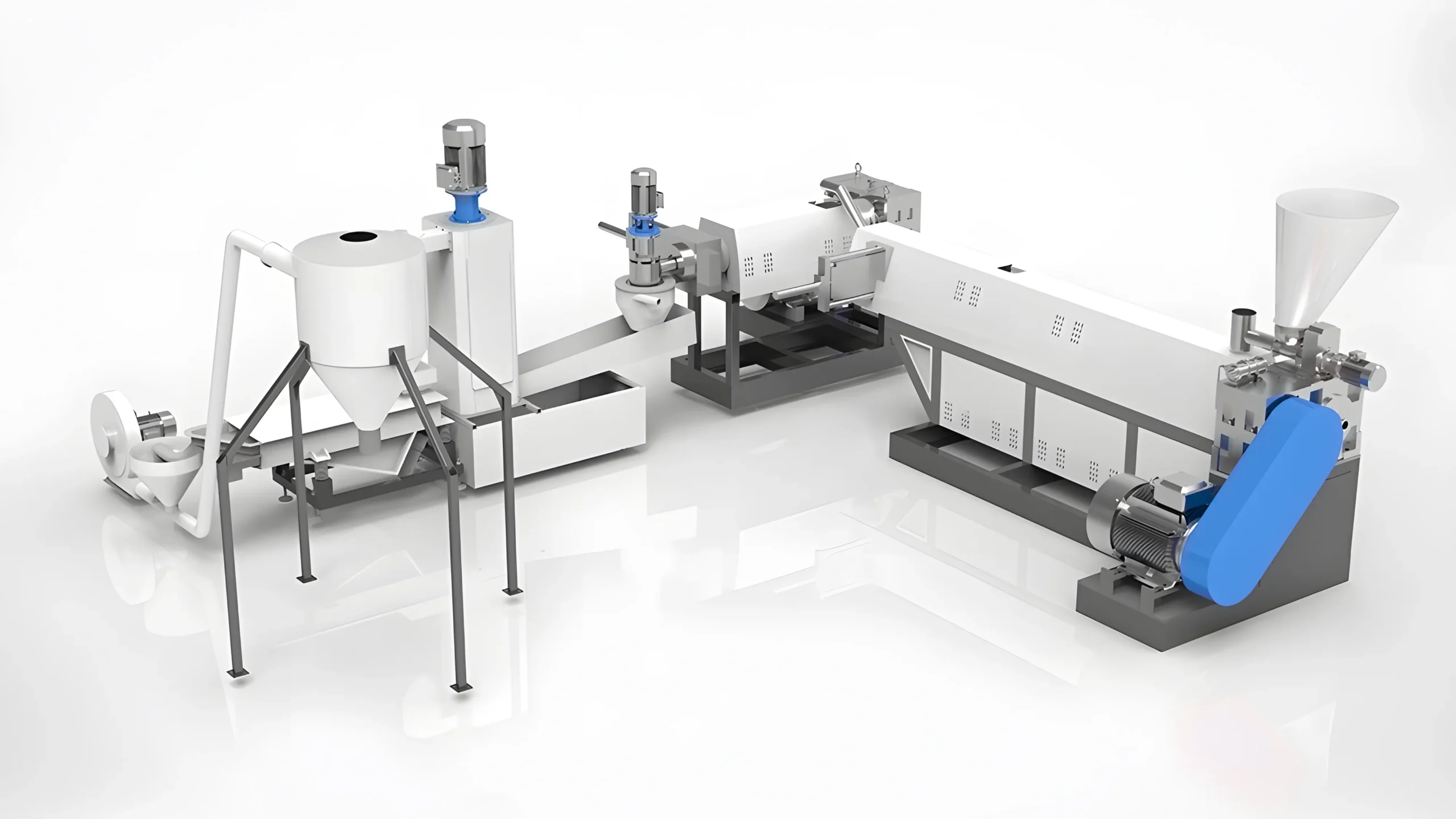

Linia dumneavoastră de granulare și reciclare a foliei BOPP de ultimă generație

Transformați eficient resturile de folie BOPP în materii prime reutilizabile, maximizând producția și reducând la minimum deșeurile. Achiziționați-vă astăzi linia de granulare de înaltă performanță!

Obțineți soluții personalizate și o ofertăDe ce să alegeți liniile noastre de granulare?

Producție crescută

20% are un randament mai mare decât modelele anterioare pentru maximizarea capacității de reciclare.

Consum redus de energie

Economisiți până la 15% la costurile cu energia datorită designului nostru eficient energetic.

Funcționare automată

Sisteme automate cu intervenție umană minimă, necesitând doar doi operatori.

Calitate superioară a peleților

Extruderele avansate produc pelete de înaltă calitate, uniforme și fără umiditate.

Aplicații versatile pentru diverse tipuri de folie BOPP

- Film BOPP imprimat

- Folie BOPP puternic imprimată

- Folie BOPP spălată

- Film BOPP metalizat

- Role de film, film liber și film legat

Procesul nostru eficient de reciclare în 7 pași

- Alimentare cu material: Folia BOPP este alimentată prin intermediul unui transportor cu bandă.

- Compactare: Pelicula este compactată pentru o alimentare uniformă.

- Extrudare și degazare: Un extruder special topește materialul, iar un sistem de degazare în vid cu două zone elimină umezeala.

- Filtrare: Sistemele avansate de filtrare asigură peleți puri.

- Peletizare: Un sistem de tăiere cu matriță cu inel de apă modelează pelete uniforme.

- Uscare: Uscarea prin vibrații îndepărtează umezeala reziduală din peleți.

- Depozitare: Peleții uscați sunt transferați în silozuri prin intermediul unui sistem pneumatic pentru depozitare.

Specificații tehnice

| Model | Diametrul șurubului | Randament (kg/h) |

|---|---|---|

| EMGL85 | Φ85mm | 180~250 |

| EMGL100 | Φ100mm | 300~400 |

| EMGL130 | Φ130mm | 500~600 |

| EMGL160 | Φ160mm | 700~800 |

| EMGL180 | Φ180mm | 1000~1500 |

Vezi-o în acțiune

Galerie de produse

Ești gata să-ți îmbunătățești eficiența în reciclare?

Contactați-ne astăzi pentru a explora soluții personalizate pentru nevoile dumneavoastră de reciclare a foliei BOPP și pentru a primi o ofertă personalizată!

Întrebări frecvente

Ce tipuri de folii BOPP pot fi reciclate?

Liniile noastre de granulare pot procesa o gamă largă de filme BOPP, inclusiv filme imprimate, puternic imprimate, post-industriale, spălate și metalizate. Sistemul este suficient de versatil pentru a procesa filme în role, resturi vrac sau forme ambalate.

Cum se compară eficiența energetică cu alte sisteme?

Sistemele noastre sunt proiectate pentru o eficiență ridicată, reducând consumul de energie cu până la 15% în comparație cu modelele convenționale. Acest lucru este realizat printr-un design optimizat al șurubului, o tehnologie avansată de încălzire și un control inteligent al motorului.

Care este calitatea peleților finali?

Produsul final este reprezentat de pelete de înaltă calitate, uniforme și dense, cu o uscare de aproape 100%. Sistemul avansat de degazare și filtrare în vid cu două zone asigură îndepărtarea substanțelor volatile și a contaminanților, ceea ce face ca peletele să fie ideale pentru reutilizarea directă în liniile de producție.