Cum maximizează personalizarea eficiența în reciclarea plasticului?

Personalizarea mașinilor de reciclare a plasticului este crucială pentru creșterea eficienței operațiunilor de reciclare. Iată cum personalizarea vă poate transforma procesul de reciclare:

- Economisirea energiei și a spațiuluiAmenajările personalizate permit utilizarea optimizată a spațiului din cadrul instalației dumneavoastră, asigurându-se că utilajele sunt amplasate astfel încât să minimizeze consumul de energie și să maximizeze randamentul. De exemplu, mașinile pot fi proiectate în forme de L, I sau U pentru a se potrivi în amenajările existente ale fabricilor, reducând necesitatea unor modificări sau extinderi ample. Această eficiență spațială se traduce direct în economii de energie, deoarece mașinile pot funcționa mai aproape de capacitatea lor optimă, fără risipa de energie asociată cu planificarea deficitară a amplasamentului.

- Adaptat la tipuri specifice de plasticNu toate materialele plastice sunt la fel; diferite tipuri necesită metode de procesare diferite. Personalizarea permite integrarea unor unelte specifice, cum ar fi tocătoare, extrudere sau peletizatoare, care sunt cele mai potrivite pentru tipurile de plastic pe care le manipulați în mod obișnuit, fie că este vorba de PET, HDPE, LDPE sau altele. Această specificitate asigură rate de recuperare mai mari și o contaminare mai mică, ceea ce este vital pentru producerea de materiale reciclate de înaltă calitate.

- Flexibilitate sporită și operațiuni simplificateCu mașini personalizate, vă puteți adapta mai ușor la fluxurile variabile de deșeuri primite. Caracteristici precum lamele de tăiere reglabile sau componentele modulare înseamnă că, pe măsură ce fluxul de deșeuri se schimbă, și utilajele dvs. se pot schimba, fără a fi nevoie de o revizie completă. Această adaptabilitate nu numai că simplifică operațiunile, dar reduce și timpii de nefuncționare, sporind productivitatea generală.

- Calitate îmbunătățită a plasticului reciclatPersonalizarea poate include sisteme de control de înaltă precizie sau sisteme de filtrare specializate care asigură puritatea și calitatea rezultatului. Concentrându-vă pe calitatea peletelor sau fulgilor reciclați, puteți deservi industriile care necesită materiale reciclate de înaltă calitate, extinzându-vă astfel piața.

- Susținerea unei economii circularePrin creșterea viabilității economice a reciclării prin eficiență, personalizarea contribuie direct la economia circulară. Aceasta încurajează mai multe companii să se implice în reciclare, reducând deșeurile de la gropile de gunoi și cererea de materiale plastice virgine.

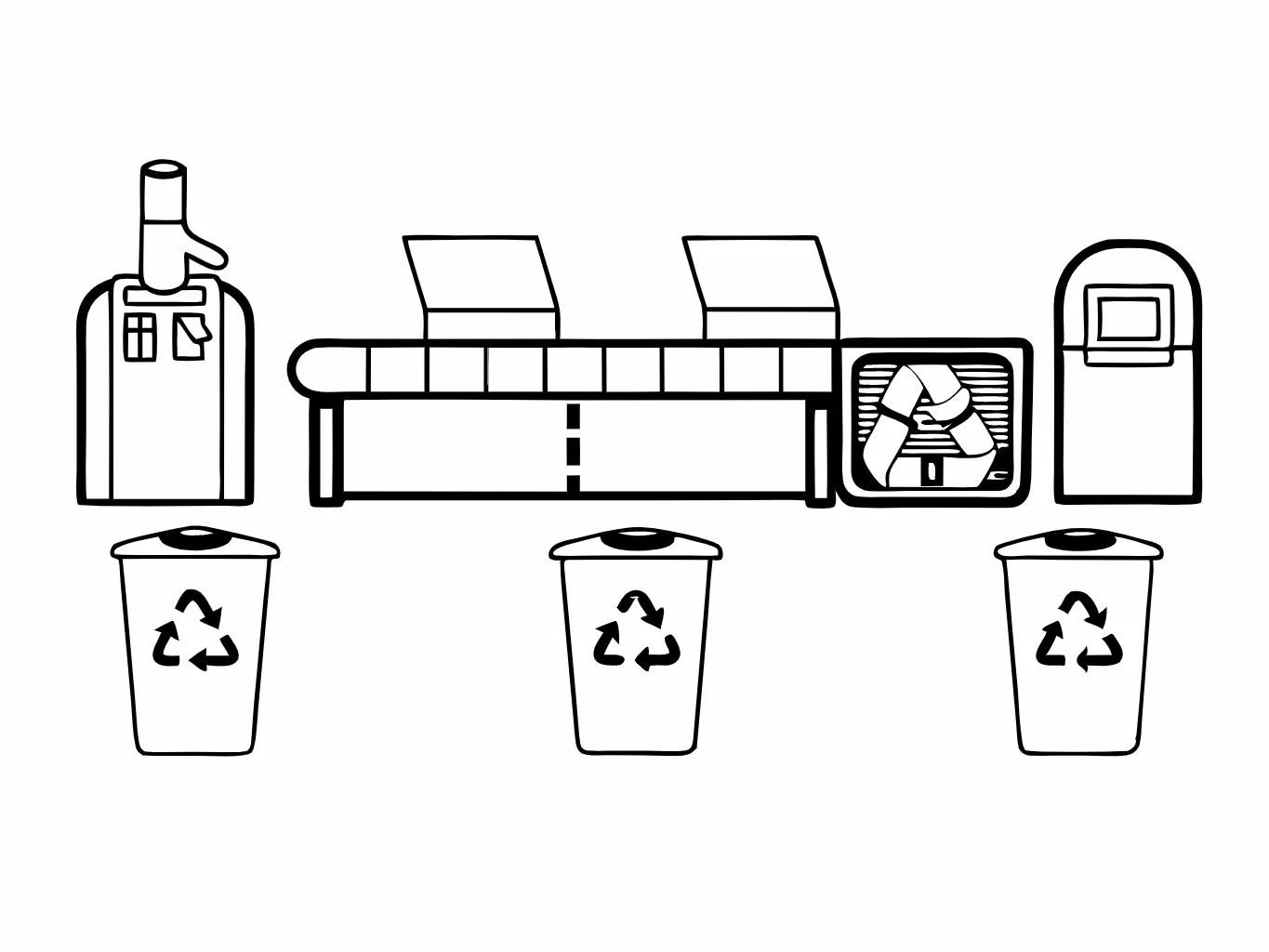

Proiectarea machetelor personalizate pentru mașinile de reciclare a plasticului

Când luați în considerare amenajarea instalației dumneavoastră de reciclare:

- Evaluează-ți spațiulEvaluați dimensiunea, forma și constrângerile instalației dumneavoastră. Configurațiile personalizate de la producători precum Rumtoo pot fi adaptate pentru a se potrivi aproape oricărui spațiu, asigurându-vă că fiecare mașină este poziționată pentru un flux optim și un consum minim de energie.

- Alege forma potrivităAlegeți între configurații în L, I sau U în funcție de fluxul de lucru. O formă de L ar putea fi ideală pentru spații mai mici unde materialele trebuie să se miște înainte și înapoi, în timp ce o formă de U poate facilita un flux continuu în zone mai mari.

- Integrați nevoile specificeFie că este vorba de un compactor cu tăietoare pentru materiale plastice mai voluminoase sau de un alimentator cu pâlnie pentru o cantitate constantă de materiale, integrarea anumitor tipuri de utilaje în configurația dvs. poate îmbunătăți drastic eficiența.

- Pregătire pentru viitorPe măsură ce operațiunile dumneavoastră cresc sau se schimbă, dispunerea de utilaje cu configurații flexibile asigură că acestea pot evolua odată cu nevoile afacerii dumneavoastră, evitând necesitatea unor cheltuieli semnificative de capital pentru utilaje noi.

De ce să optați pentru personalizare?

- Beneficii economiceMașinile personalizate pot duce la o amortizare mai rapidă a investiției datorită eficienței și adaptabilității lor la profilul specific al deșeurilor.

- Impactul asupra mediuluiPrin optimizarea procesului de reciclare, reduceți consumul de deșeuri și energie, diminuând amprenta de carbon.

- Competitivitatea piețeiOferirea de produse reciclate de înaltă calitate poate deschide noi segmente de piață, de la ambalaje la producție, unde conținutul reciclat este din ce în ce mai apreciat.

Concluzie

Personalizarea dvs. mașină de reciclare a plasticului Amenajarea nu înseamnă doar montarea echipamentelor în spațiul tău; este vorba despre redefinirea modului în care gestionezi deșeurile de plastic pentru a face fiecare parte a procesului mai eficientă. Concentrându-se pe cum să personalizezi, ce să iei în considerare și de ce este important, companiile își pot îmbunătăți semnificativ operațiunile de reciclare. Pentru informații detaliate sau pentru a discuta despre nevoile tale specifice, nu ezita să... contactaţi-ne pentru mai multe detalii despre personalizarea aspectului mașinii.

Această abordare nu numai că se aliniază cu obiectivele de sustenabilitate, dar poziționează și afacerea dumneavoastră ca lider în reciclarea eficientă și de înaltă calitate a plasticului.