Revoluționează reciclarea foliei de plastic

Linia noastră inovatoare de mărunțire și densificare a foliei PP PE transformă foliile reziduale dificile în materiale valoroase și reutilizabile. Este o modalitate mai inteligentă de a recicla folia de plastic!

De ce să alegeți linia noastră de densificare a foliei PP PE?

Rezultat de înaltă calitate

Produce material densificat premium, perfect pregătit pentru peletizare sau reciclare chimică.

Procesare eficientă

Transformă baloți dificili de folii PP/PE murdare sau mixte cu o eficiență de neegalat.

Soluție ecologică

Reduce semnificativ deșeurile de plastic și susține o economie cu adevărat circulară pentru materialele plastice.

Versatil și personalizabil

Oferă opțiuni de personalizare pentru a se potrivi perfect cerințelor dumneavoastră operaționale specifice.

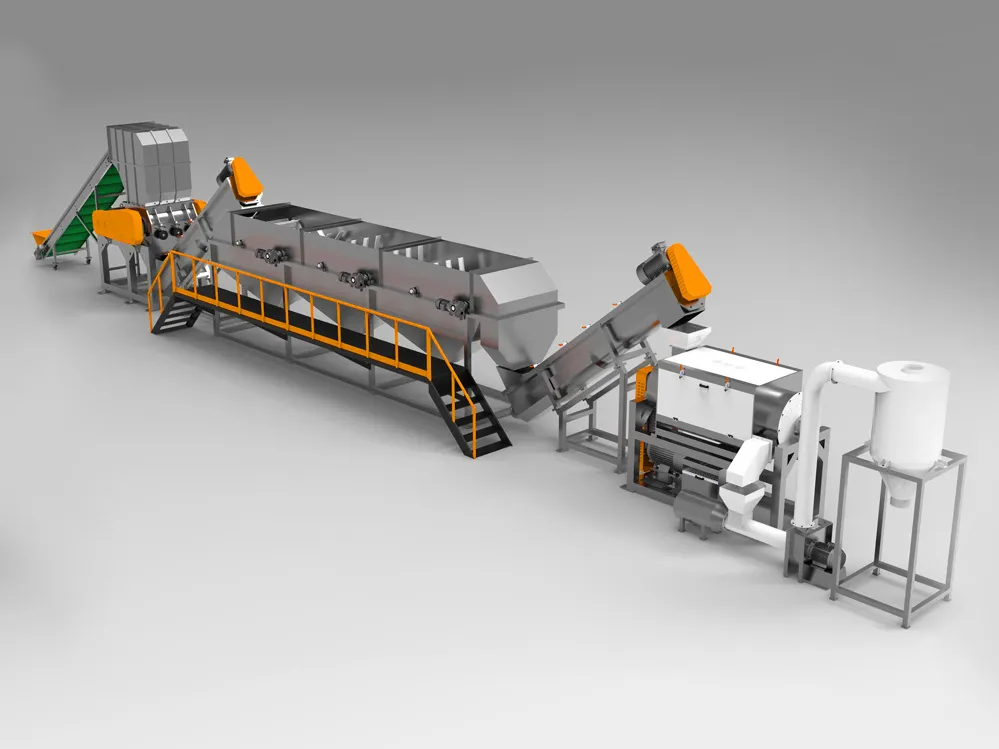

Cum funcționează: Transformare pas cu pas

Sistemul nostru avansat transformă baloții dificili de folii PP/PE murdare în material densificat de înaltă calitate printr-un proces meticulos în mai multe etape.

1Putere de mărunțire

Călătoria începe cu tocătorul nostru robust, special conceput pentru a descompune eficient baloți mari și compactați de folii de plastic. Bucățile tocate se deplasează apoi lin pe o bandă transportoare, gata pentru următorul pas vital.

2Precizie a granulării umede

Apoi, materialul intră în granulatorul umed. Aici, cuțite rotative de mare viteză taie cu precizie pelicula în fulgi mici și uniformi. O sită integrată asigură că doar fulgii de dimensiunea perfectă sunt eliminați, optimizându-i pentru densificare.

3Puritatea separării chiuvetei/plutitorului

Curățenia este esențială! Fulgii sunt transferați într-un rezervor de separare cu chiuvetă/plutitor. Acest proces inteligent folosește densitatea apei pentru a separa pelicula de plastic valoroasă (care plutește) de contaminanții mai grei (care se scufundă), asigurând o materie primă pură.

4Excelență în comprimare și densificare

În cele din urmă, pelicula curată și umedă intră în dispozitivul de stoarcere-densificare. Folosind o presă cu șurub puternică și o încălzire controlată, această unitate îndepărtează eficient apa și comprimă pelicula în pelete dense, neregulate (densitate de aproximativ 350-410 kg/m³), gata pentru următoarea lor utilizare.

Vedeți linia de densificare a foliei PP PE în acțiune!

Urmăriți acest videoclip pentru a vedea cum sistemul nostru avansat transformă baloții de folie PP/PE în material densificat de înaltă calitate.

Caracteristici detaliate și specificații tehnice

Avantajele cheie ale sistemului

- ✔ Transformă eficient baloții de folii PP/PE murdare.

- ✔ Produce material densificat de înaltă calitate (lungime aprox. 50 mm, densitate 350-410 kg/m³).

- ✔ Granulator secundar opțional pentru particule de dimensiuni mai mici.

- ✔ Opțiuni de personalizare pentru a se potrivi perfect nevoilor dumneavoastră operaționale specifice.

Beneficiile tehnologiei uscătorului de extrudare multifuncțional

- ➤ Reduce dramatic conținutul de umiditate până la doar 3% (de la o valoare inițială de ~30% pentru pelicula subțire).

- ➤ Crește semnificativ densitatea în vrac, de până la 10 ori.

- ➤ Compactează eficient materialul pentru o manipulare și depozitare mai ușoare.

Specificații tehnice

| Model | Operațiune (Personal) | Putere instalată (kW) | Materialul cuțitului | Capacitate (kg/h) |

|---|---|---|---|---|

| RTM-200 | 2-3 | 160-200 | SKD11 | 200 |

| RTM-500 | 2-3 | 200-240 | SKD11 | 500 |

| RTM-1000 | 2-3 | 400-450 | SKD11 | 1000 |

Toate mașinile noastre de reciclare vin cu o garanție limitată de 1 an.

Prezentare echipamente și materiale procesate

Şurub

Peletizare

Plasă de ecran

Partenerul dumneavoastră în reciclarea sustenabilă

Linia de mărunțire și densificare a foliei PP PE reprezintă un salt semnificativ înainte în tehnologia de reciclare a plasticului. Prin procesarea eficientă a foliilor de plastic post-consum sau post-industriale, acest sistem nu numai că simplifică operațiunile de reciclare, dar aduce și o contribuție concretă la reducerea impactului asupra mediului. Adoptați această soluție avansată pentru a vă îmbunătăți eforturile de reciclare și a susține o economie cu adevărat circulară pentru materialele plastice.

Ești gata să-ți îmbunătățești capacitățile de reciclare?

Pentru cele mai recente prețuri, termene de livrare sau pentru a discuta despre opțiunile de personalizare, vă rugăm să ne trimiteți un mesaj folosind formularul de mai jos. Suntem aici pentru a vă ajuta!

Întrebări frecvente (FAQ)

Ce tipuri de folie de plastic poate procesa această linie?

Această linie este special concepută pentru a procesa baloți de folii de polipropilenă (PP) și polietilenă (PE) murdare sau curate, inclusiv surse post-consum și post-industriale, cum ar fi folii agricole, folii de ambalare și deșeuri industriale.

Care este conținutul final de umiditate al materialului densificat?

Datorită tehnologiei noastre avansate de comprimare și densificare, conținutul de umiditate din materialul final densificat este redus dramatic la aproximativ 3%, față de aproximativ 30% inițial pentru pelicula subțire.

Care este densitatea volumetrică tipică a materialului de ieșire?

Materialul densificat atinge de obicei o densitate volumetrică de aproximativ 350-410 kg/m³, ceea ce îl face semnificativ mai ușor de manipulat, depozitat și transportat pentru prelucrare ulterioară.

Poate fi personalizată linia conform cerințelor specifice?

Da, oferim opțiuni de personalizare pentru a se potrivi perfect nevoilor dumneavoastră operaționale specifice. Acestea pot include ajustări ale capacității, integrarea unor granulatoare secundare opționale pentru particule de dimensiuni mai mici și alte modificări. Vă rugăm să ne contactați pentru a discuta despre cerințele dumneavoastră.

Ce garanție este oferită odată cu mașinile?

Toate mașinile noastre de reciclare, inclusiv linia de mărunțire și densificare a foliei PP PE, vin cu o garanție limitată completă de 1 an pentru liniștea dumneavoastră.