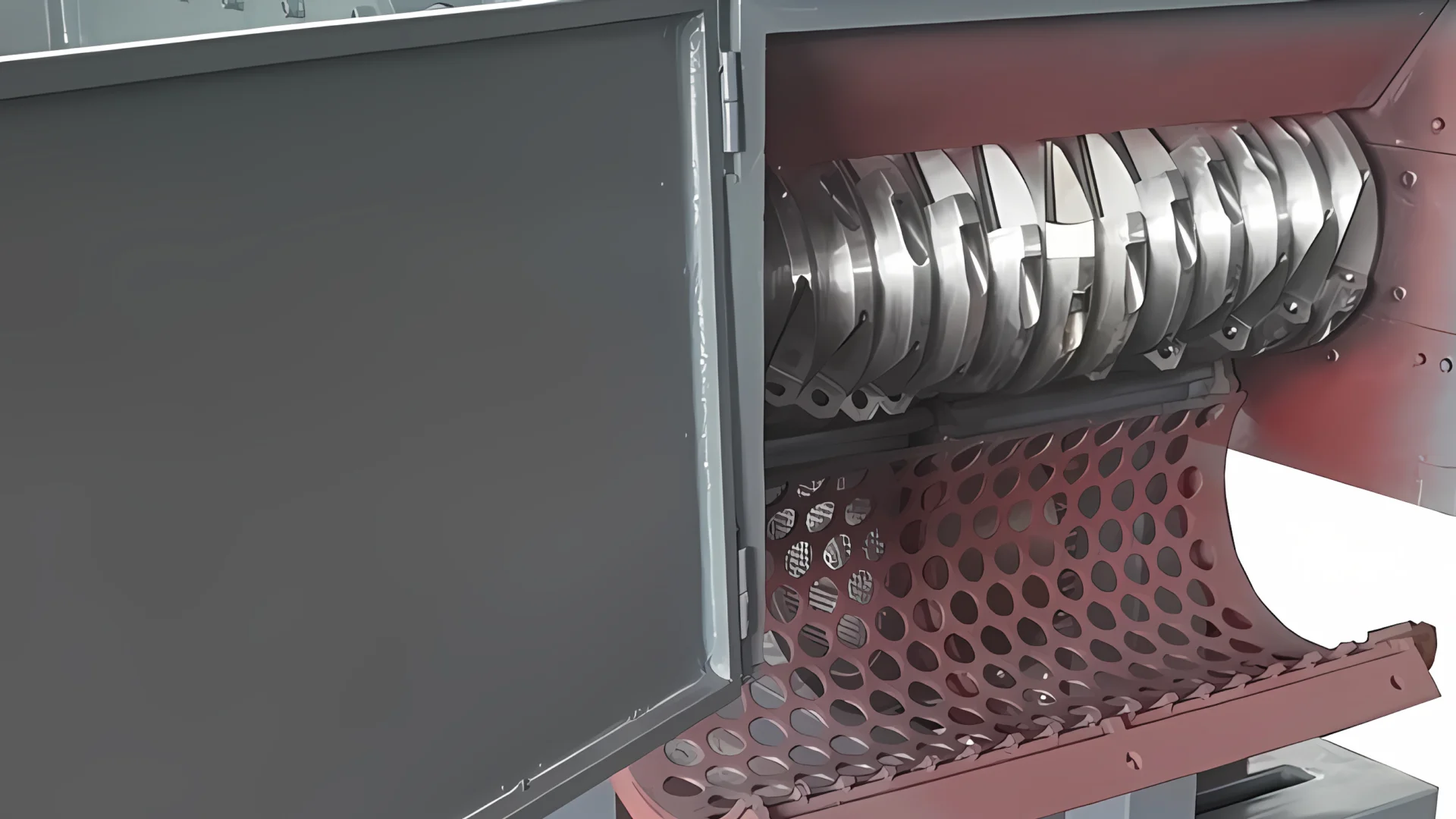

Înțelegerea complexității unui Tocător cu un singur arbore poate fi crucial pentru cei care operează în industria de reciclare sau de gestionare a deșeurilor. Acest tip de tocător joacă un rol esențial în reducerea dimensiunii diferitelor materiale, făcând ca componentele sale să fie parte integrantă a funcției sale. Să analizăm componentele cheie care definesc eficiența și eficacitatea sa.

Importanța rotorului într-un tocător cu un singur arbore

Funcționalitate de bază:

Rotorul este inima tocătorului cu un singur arbore. De obicei, acesta este echipat cu lame robuste și durabile, aranjate într-un model specific pentru a maximiza procesul de tocare. Designul și viteza de rotație a rotorului sunt esențiale pentru a determina eficacitatea tocătorului în procesarea diferitelor materiale.

Impactul asupra procesului de mărunțire:

- Cuplu și vitezăCuplul ridicat la viteze mici este caracteristic acestor rotoare, permițându-le să manipuleze materiale dure fără uzură excesivă.

- Manipularea materialelorConfigurația rotorului poate influența, de asemenea, capacitatea sa de a procesa diverse dimensiuni și tipuri de materii prime, de la materiale plastice la metale.

Semnificația tăierii lamelor într-un tocător cu un singur arbore

Eficiență de tăiere:

Lamele sunt direct responsabile pentru acțiunea de mărunțire. Materialul, ascuțimea și amplasarea lor pe rotor afectează eficiența cu care tocătorul poate tăia materialele.

Contribuții la eficiența mașinilor:

- Reducerea materialelorLamele ascuțite și bine întreținute asigură o reducere consistentă a dimensiunii materialului, aspect crucial pentru procesele ulterioare de reciclare.

- UzurăCalitatea palelor influențează, de asemenea, frecvența întreținerii și înlocuirii, afectând costurile operaționale generale.

Rolul sistemului hidraulic într-un tocător cu un singur arbore

Control și flexibilitate:

Sistemul hidraulic dintr-un tocător cu un singur arbore oferă un control îmbunătățit asupra procesului de tocare. Acesta permite reglarea presiunii și a vitezei în funcție de materialul procesat, ceea ce este vital pentru prevenirea blocajelor și optimizarea randamentului.

Beneficiile controlului hidraulic:

- Ajustarea procesuluiOperatorii pot regla fin acțiunea de mărunțire, adaptându-se la diferite materiale din mers.

- Întreținere și siguranțăSistemul hidraulic facilitează accesul mai ușor la componentele interne ale tocătorului pentru întreținere și oferă mecanisme de siguranță pentru a proteja mașina și operatorii în timpul funcționării.

Înțelegerea acestor componente cheie - rotorul, lamele de tăiere și sistemul hidraulic - oferă o perspectivă asupra capacităților operaționale și a eficienței unei mașini de tuns. Tocător cu un singur arboreFiecare componentă este crucială pentru asigurarea funcționării optime a tocătorului, adaptându-se la diverse materiale și cerințe operaționale. Recunoscând importanța acestor componente, operatorii își pot întreține mai bine echipamentul, pot prelungi durata de viață a acestuia și le pot optimiza performanța pentru nevoile lor specifice de tocare.