Uscarea este unul dintre cele mai mari costuri operaționale într-o linie de reciclare a plasticului. Decizia nu este “uscător centrifugal vs. aer cald”. Este cât de mult trebuie să împingi umezeala în jos înainte de următorul pas (împachetare în saci, extrudare, peletizare).

Acest ghid explică diferența dintre consumul de energie pentru deshidratarea mecanică (centrifugarea apei în vrac) și uscarea termică cu aer (evaporarea apei), plus o modalitate simplă de a estima energia în funcție de cantitatea de apă eliminată.

Concluzii rapide

- Folosește mai întâi deshidratarea mecanică; uscarea termică devine costisitoare, deoarece trebuie să evapori apa.

- “Suficient de uscat” depinde de polimer și de următorul pas al procesului; nu uscați excesiv decât dacă specificațiile o cer.

- Urmăriți umiditatea la descărcare și kWh/tonă; cea mai bună configurație a uscătorului este cea care îndeplinește specificațiile cu un randament stabil.

Referințe Energycle conexe: – Uscător centrifugal pentru aplicații de reciclare – Cum funcționează uscătoarele centrifugale (ghid clar) – Ghidul complet pentru mașinile de uscare termică în reciclarea plasticului

Fizica deshidratării

- Uscare mecanică: Se bazează pe energia cinetică (forța centrifugă) pentru a separa fizic apa de suprafață de fulgii de plastic. Acest proces este foarte eficient pentru îndepărtarea apei în vrac, dar nu poate îndepărta umiditatea de suprafață legată la nivel molecular.

- Uscare termică (cu aer cald): Folosește căldură + flux de aer pentru a evapora apa. Acest lucru este necesar pentru lustruirea finală, dar necesită mult mai multă energie pentru a trece de la lichid la gaz.

Notă privind formularea: “uscarea la aer” poate însemna uscare la temperatură ambientală (fără adaos de căldură) sau uscare cu aer cald (aer încălzit). În liniile de reciclare, etapa de “lustruire finală” este de obicei uscarea cu aer încălzit, deoarece aerul ambiant atinge rareori o umiditate scăzută și stabilă la debitele industriale.

Uscătoare centrifugale mecanice: impact ridicat, cost redus

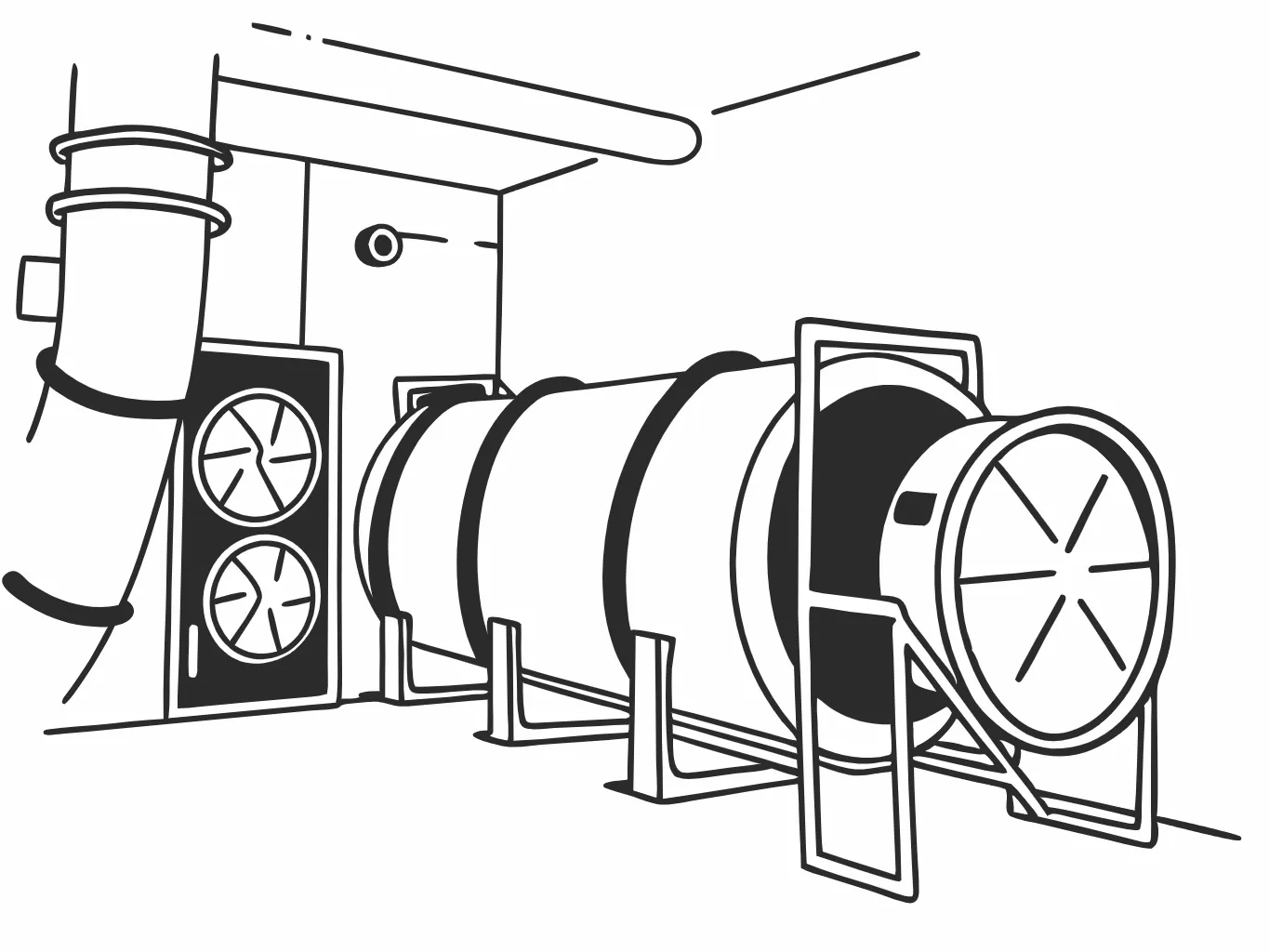

Situat imediat după sârma de spălat, uscătorul centrifugal este “greul”.”

Principiul de funcționare

Fulgii umezi intră într-un rotor calibrat care se rotește la turații mari (de obicei 1200-1500 RPM). Materialul este accelerat împotriva unei site perforate. Apa trece prin sită, în timp ce fulgii uscați se deplasează în sus spre evacuare.

Profil energetic

- Intrare principală: Motor de curent alternativ (de obicei 45 kW până la 90 kW pentru o linie de 1 tonă/oră).

- Eficienţă: Un uscător mecanic poate reduce umiditatea de la 30% la aproximativ 2-3%.

- De ce economisește energie: Pentru a elimina apa prin evaporare, trebuie să furnizați căldură latentă. Filarea elimină apa fără a plăti acel cost energetic de “schimbare de fază”.

Beneficii: * Reducere instantanee a umidității. * Amprentă fizică redusă. * Îndepărtează contaminanții (particule fine/hârtie) împreună cu apa.

Uscare termică cu aer cald: Lustruirea finală

Adesea numită “uscare rapidă cu aer cald” sau “uscare în spirală”, această etapă urmează de obicei uscarea mecanică pentru a obține specificațiile produsului final.

Principiul de funcționare

Fulgii pre-uscați sunt transportați printr-un sistem de conducte lungi și izolate folosind aer cald de mare viteză. Aerul este încălzit prin rezistențe electrice, arzătoare pe gaz sau schimbătoare de căldură cu abur.

Profil energetic

- Intrări principale: Motor ventilator (transport) + Elemente de încălzire (evaporare).

- Eficienţă: Reduce umiditatea de la ~3% la <0,5%.

- De ce costă mai mult: Evaporarea apei necesită căldură latentă. La 100°C, entalpia de vaporizare a apei este de aproximativ 2.257 kJ/kg (valoarea variază în funcție de temperatură).

Beneficii: * Atinge niveluri finale de umiditate foarte scăzute, potrivite pentru extrudare. * Manipulare delicată (fără uzură mecanică a fulgilor).

Unde se potrivește uscarea cu aer ambiental (și unde nu)

Uscarea la aer ambiental poate părea “ieftimă” pe hârtie (fără încălzitoare), dar este de obicei limitată de: – Timpi lungi de uscare și suprafață mare a podelei – Variații meteorologice/sezonier (umiditate finală instabilă) – Risc de praf/contaminare în timp ce materialul este expus

În practică, uscarea la aerul ambiental poate fi acceptabilă pentru drenaj temporar sau stocare necritică, dar rareori înlocuiește etapele mecanice + termice atunci când aveți nevoie de umiditate repetată pentru extrudare.

Combinație strategică pentru eficiență

Bazarea exclusivă pe uscarea termică este dezastruoasă din punct de vedere economic; bazarea exclusivă pe uscarea mecanică este insuficientă pentru o extrudare de înaltă calitate.

Abordarea “hibrid”: Cele mai eficiente linii de reciclare din punct de vedere energetic utilizează o abordare în mai multe etape: 1. Etapa 1 – Mecanică: Două uscătoare centrifuge în serie. Primul elimină 80% de apă; al doilea o reduce la aproximativ 2-3%. 2. Etapa 2 – Termică: Un sistem final de conducte spiralate cu aer cald necesită de obicei doar o mică diferență de temperatură (de exemplu, 60-80°C) pentru a elimina umezeala rămasă la suprafață.

Ce obiectiv de umiditate ai nevoie de fapt?

Folosește acestea ca puncte de plecare practice; specificațiile cumpărătorului și comportamentul polimerilor reprezintă autoritatea finală.

| Etapa din aval | Țintă tipică de umiditate | De ce contează |

|---|---|---|

| Împachetarea / depozitarea fulgilor spălați | ~2% până la 5% | Previne picurarea și reduce aglomerarea; de obicei, se poate realiza cu o deshidratare bună |

| Extrudare / peletizare (general) | Adesea <1% (în mod obișnuit <0.5%) | Reduce aburul/bulele, instabilitatea presiunii și defectele de suprafață |

| Produse cu sensibilitate ridicată (dependente de majuscule/minuscule) | Pot fi necesare obiective mai mici | Unii polimeri și utilizări finale necesită un control mai strict al umidității și etape suplimentare de uscare. |

Comparație a costurilor energiei (exemplu simplu și direcțional)

Presupuneți că procesați 1.000 kg/h de plastic uscat.

| Tip de Sistem | Ce face | Principalul motor energetic | Indicații de plecare |

|---|---|---|---|

| Numai mecanic | Îndepărtează apa în exces după spălare | Puterea motorului (kW) și sarcina | Uscare cu costuri reduse, dar este posibil să nu atingă umiditatea de grad de extrudare |

| Numai termic | Evaporează cea mai mare parte a apei fără a o deshidrata | Căldura latentă de vaporizare + puterea suflantei | Energie foarte mare dacă încercați să evaporați apa “în vrac” |

| Hibrid optimizat | Deshidratați mai întâi, apoi evaporați ultima fracțiune | Sarcină termică mică după deshidratare | Cel mai bun echilibru între specificații, stabilitate și costuri de operare |

O estimare simplă a consumului de energie (utilizabilă pentru planificarea completă)

Dacă linia ta trebuie să se evapore W kg de apă pe oră, aportul teoretic minim de căldură (fără pierderi) este:

Energie (kWh/h) ≈ (W × 2.257 kJ/kg) ÷ 3.600

Asta înseamnă evaporarea 1 kg de apă este vorba despre 0,63 kWh la minimul teoretic. Sistemele reale utilizează mai mult (pierderi de căldură, aer evacuat, transfer imperfect de căldură). Pentru planificare, multe instalații presupun un multiplicator (adesea ~1,5× până la 3×) în funcție de tipul de uscător și de recuperarea căldurii.

Exemplu (direcțional): Dacă materialul după uscare centrifugă are o umiditate de ~3% și aveți nevoie de ~0,5% pentru extrudare, apa rămasă de îndepărtat ar putea fi de ordinul a ~25–30 kg/h la 1.000 kg/h de plastic uscat, ceea ce implică deja ~16–19 kWh/h căldură teoretică înainte de pierderi și puterea suflantei.

De ce “numai termic” devine rapid scump: Dacă materialul spălat intră în uscare la o umiditate de ~30% și totuși aveți nevoie de ~0,5%, este posibil să vă evaporați. sute de kg/h de apă la 1.000 kg/h de plastic uscat - direcțional 250+ kWh/h căldură teoretică înainte de pierderi.

Motive frecvente pentru care plantele cheltuiesc prea mult pe uscare

- Omiterea deshidratării: Trimiterea fulgilor care “picurează” în uscarea cu aer cald forțează încălzitorul să facă munca pe care ar trebui să o facă o centrifugă.

- Fără măsurare a umidității: Operatorii ajustează în funcție de senzația tactilă, ceea ce înseamnă de obicei uscare excesivă (energie irosită) sau uscare insuficientă (defecțiuni de calitate).

- Neglijarea ecranului și a fluxului de aer: O sită obstrucționată sau o evacuare restricționată reduce performanța de deshidratare și face ca etapa termică să funcționeze mai greu.

Caz special: Linii de film (storcător vs. centrifugal)

Dacă uscați pelicula spălată, deshidratarea mecanică folosește adesea un stoarcător (mai degrabă decât un uscător centrifugal) pentru a îndepărta apa și a densifica pelicula înainte de lustruirea termică. Pentru un punct de referință, consultați Energycle. Storcător termic centrifugal pentru deshidratarea plasticului şi tehnologia.squeezeur.fil.plastic.

Concluzie

Uscătoarele mecanice elimină eficient apa în vrac; uscarea termică este etapa finală atunci când specificațiile produsului o impun. Dacă dimensionați și operați corect etapa mecanică, puteți de obicei reduce sarcina termică și stabiliza umiditatea finală.