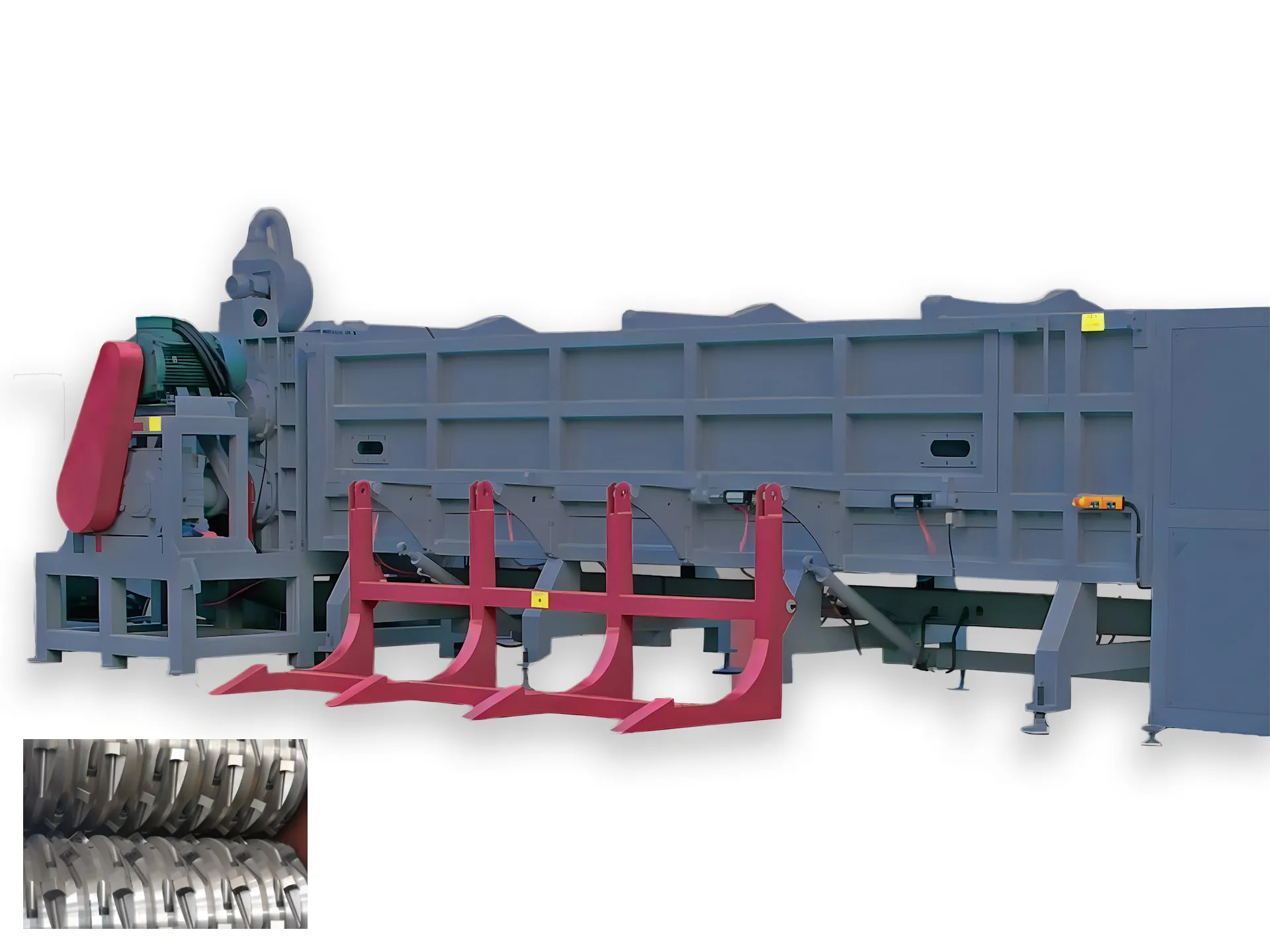

In the evolving world of recycling and waste management, the Heavy Duty HDPE Plastic Pipe Shredder System emerges as a pinnacle of efficiency and innovation. Engineered with precision, this advanced system effortlessly processes a diverse range of materials, showcasing cutting-edge technology and a steadfast dedication to sustainability.

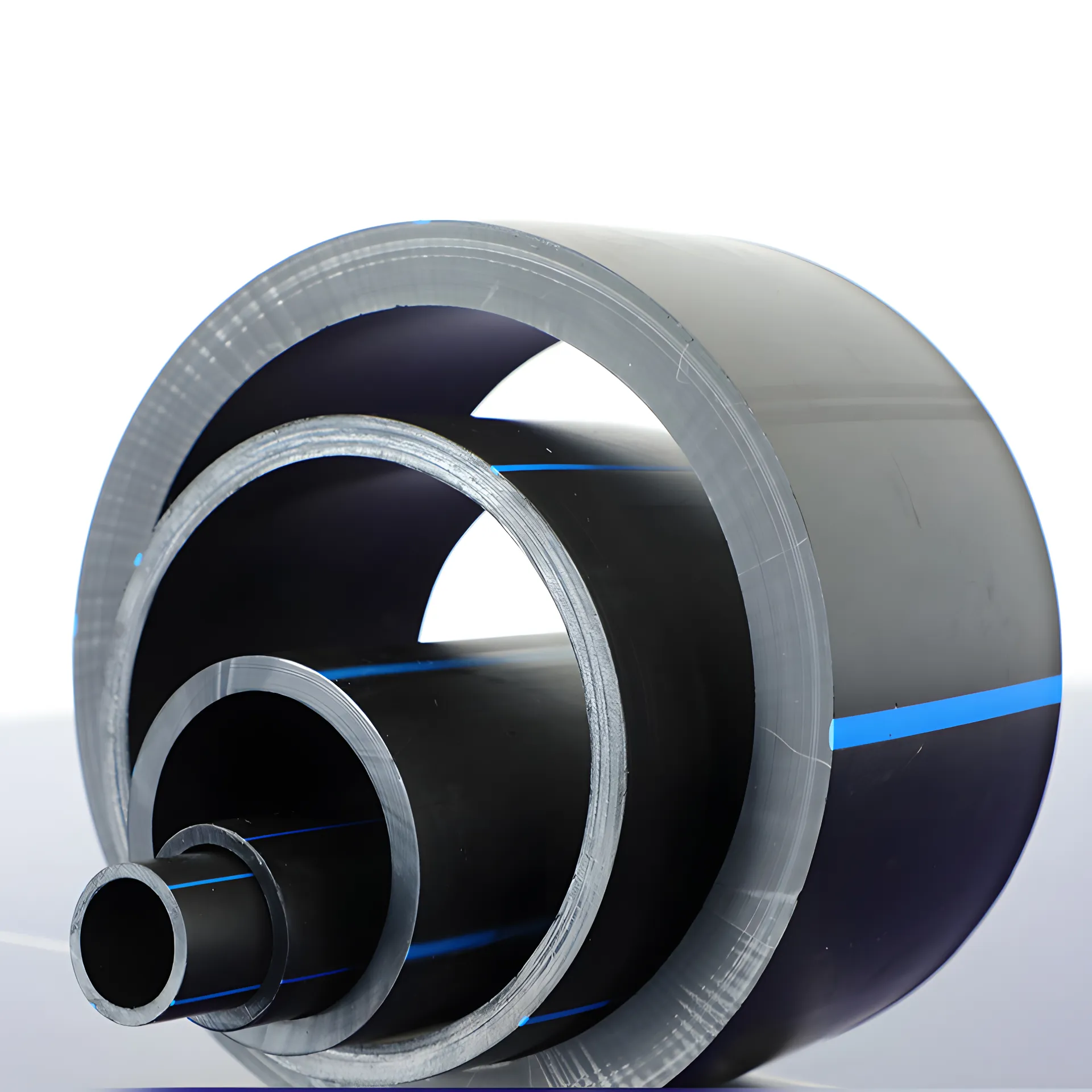

What Is HDPE and Why It Matters

High-Density Polyethylene (HDPE) is a robust, versatile plastic widely used in applications like water pipes, packaging, and industrial containers. Known for its durability, flexibility, and chemical resistance, HDPE is a staple across industries. Yet, its disposal poses significant environmental challenges. Our HDPE shredder system transforms this potential waste into valuable, reusable resources, supporting a greener future.

Key Features of the HDPE Shredder System

- Unmatched Versatility: Optimized for large-diameter HDPE, PP, and PVC pipes, this system also excels at shredding plastic lumps, stacked waste bins, and pallets with ease.

- Advanced Hydraulic Feed: A state-of-the-art hydraulic pushing device ensures safe, efficient material feeding, minimizing manual effort and delivering uniform shredding results.

- Two-Stage Crushing: After initial shredding, materials are seamlessly transferred to a secondary crusher, preparing them for recycling or further processing.

- Smart PLC Controls: Featuring a modern PLC control system, this shredder offers reliability, intuitive operation, and simplified maintenance for today’s waste management demands.

HDPE Shredder System Specifications

| Shredder Model | Shaft Diameter (mm) | Moving Knife Qty. (pcs) | Maximum Capacity (kg/h) | Motor Power (KW) | Chamber Size (L x W) (mm) | Host Weight (kg) | Dimensions (L x W x H) (mm) |

|---|---|---|---|---|---|---|---|

| RTM-W600 | 350 x 2 | 63 | 800 | 30 + 37 | 6200 x 670 | 11000 | 12500 x 2500 x 1800 |

| RTM-W800 | 450 x 2 | 108 | 1000 | 37 + 45 | 6200 x 870 | 14000 | 12800 x 2900 x 2000 |

| RTM-W1000 | 550 x 2 | 132 | 1200 | 45 + 55 | 6200 x 1100 | 20000 | 13100 x 3260 x 2150 |

| RTM-W1200 | 650 x 2 | 195 | 1500 | 55 + 75 | 6200 x 1300 | 23000 | 13100 x 3460 x 2300 |

| RTM-W1600 | 430 x 4 | 400 | 1800 | 75 + 90 | 6200 x 1700 | 25000 | 13100 x 3700 x 2500 |

How the Shredder System Works

Operating the HDPE plastic pipe shredder is simple yet highly effective. Materials are loaded into the feeding section, where the advanced hydraulic pushing device guides them into the shredding chamber. After the initial breakdown, a conveyor transports the shredded pieces for secondary crushing, ensuring optimal size reduction for recycling.

For a complete recycling solution, pair this system with Rumtoo Machine’s granulators and pulverizers. This integrated setup delivers a seamless, turnkey process, maximizing efficiency and minimizing waste in your operations.

Advantages for Businesses

- Cost Savings: On-site recycling reduces disposal expenses and creates opportunities to profit from selling processed materials.

- Sustainability: Adopting this eco-friendly system highlights your business’s commitment to reducing environmental impact.

- Space Optimization: Shredding and recycling waste streamlines storage needs, freeing up valuable facility space.

Conclusion

The Heavy Duty HDPE Plastic Pipe Shredder System transcends traditional machinery—it’s a comprehensive waste management solution. Ideal for manufacturers, recyclers, and industries handling plastic waste, this system delivers reliability and efficiency while promoting sustainable practices.

Why Choose Our HDPE Shredder System?

- Multi-Purpose Design: Perfect for long pipes, bulky lumps, and high-volume tanks.

- Precision Control: The PLC system ensures dependable performance, ease of use, and low maintenance.

- Green Technology: A sustainable answer to plastic waste in an environmentally conscious world.

Ultimately, the Heavy Duty HDPE Plastic Pipe Shredder System is an essential investment for businesses seeking a robust, eco-friendly recycling solution. Engineered to tackle modern waste challenges, it offers a practical and sustainable approach to managing plastic waste effectively.

INQUIRIES

For the latest pricing and lead times, contact us using the form below.

[…] Heavy Duty HDPE Plastic Pipe Shredder System […]