Plastic recycling line

Our state-of-the-art technology enables efficient processing of various types of plastics, ensuring maximum recovery and minimal waste. From shredders to granulators, we offer a full range of machines that handle everything from collection and sorting to reprocessing and pelletizing.

01

Advanced Recycling Technology

Our plastic recycling machines use advanced recycling technology, efficiently converting plastic waste into high-quality granules. This process minimizes energy consumption and maximizes output, enabling businesses to produce recyclables that meet industry standards.

02

Compact and Modular Design

Our recycling machines feature a compact, modular design, ideal for facilities with limited space. This design allows for easy integration into existing production lines, facilitating a seamless switch to sustainable practices without significant disruption.

03

User-Friendly Interface

Equipped with a user-friendly interface, our plastic recycling machines simplify operation and monitoring. Operators can easily control parameters, receive real-time data, and quickly troubleshoot issues, ensuring smooth, efficient recycling processes.

04

Robust Material Handling System

Our machines come with a robust material handling system capable of managing a wide range of plastic types and sizes. This versatility ensures that various plastic waste streams can be processed, maximizing recycling potential and minimizing waste.

05

Energy Efficiency and Sustainability

Designed with energy efficiency in mind, our plastic recycling machines reduce operational costs and carbon footprints. By implementing energy-saving technologies and sustainable practices, we help businesses meet environmental goals while enhancing profitability.

06

Full Support and Maintenance

We offer comprehensive support and maintenance services for our recycling machines. From installation to regular maintenance checks, our experienced team ensures optimal performance and longevity of your equipment, helping you achieve continuous recycling success.

Categories PET Bottle Recycling Washing Line

Posted on

Transform waste bottles into high-purity PET flakes with our automated washing line. Customizable capacities (500-5000kg/h) and superior water efficiency. Get your quote!

Categories MSW sorting machine

Posted on

A complete solution for processing municipal solid waste (MSW). Our integrated sorting systems automate the segregation of recyclables like plastics, metals, and paper, dramatically diverting waste from landfills. Featuring components from bag breakers and trommel screens to advanced optical sorters, these plants are engineered for maximum resource recovery and efficiency. The essential core of any modern Material Recovery Facility (MRF).

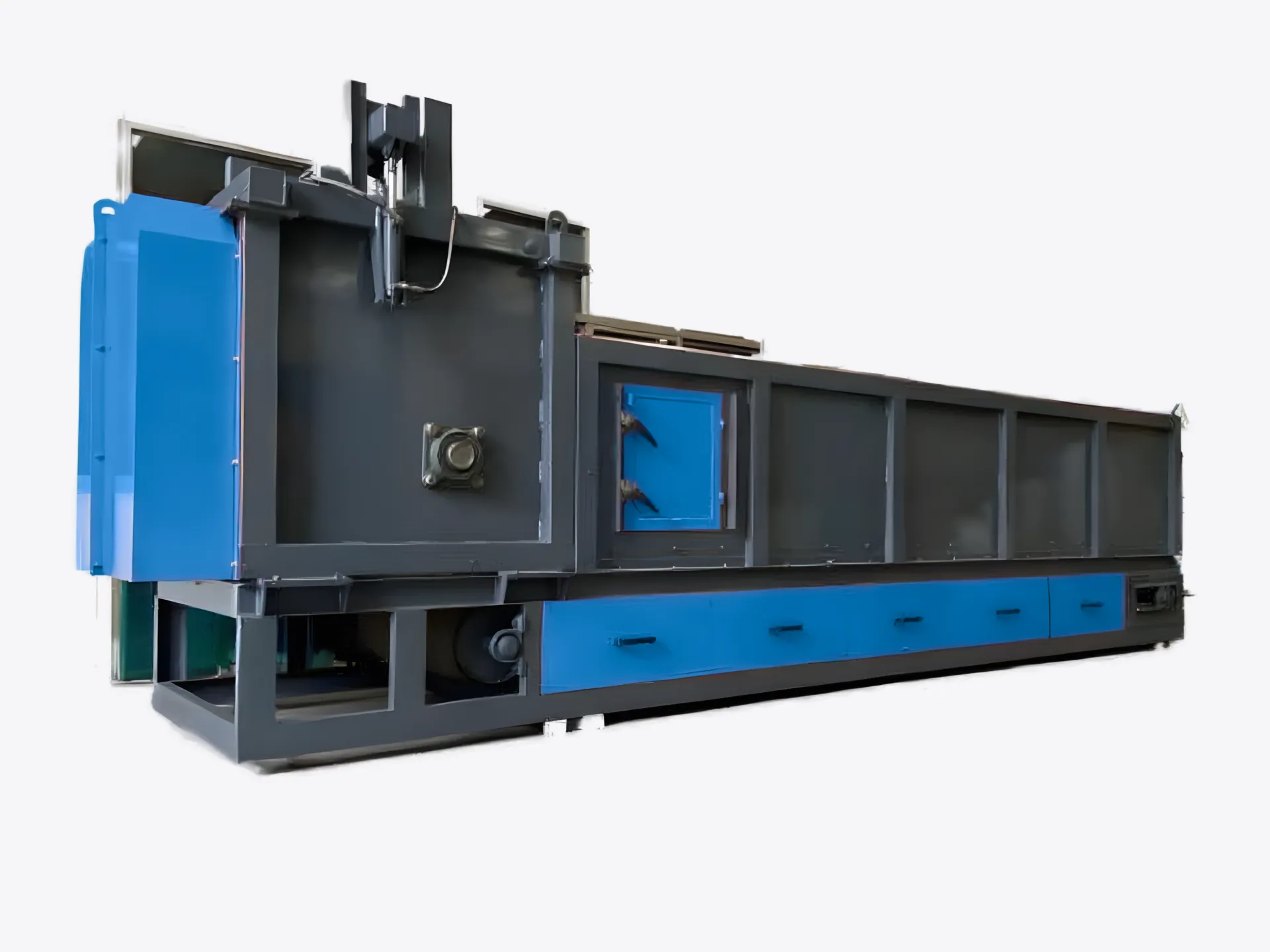

Categories Assistive System, MSW sorting machine

Posted on

Our Intelligent Bag Breaker & Bale Opener is the ultimate front-end solution for modern recycling facilities. Engineered for both high-density PET bales and bagged municipal solid waste (MSW), this heavy-duty machine guarantees over 98% opening efficiency without damaging valuable materials. It ensures a consistent, liberated material stream, dramatically improving the performance of downstream sorting systems. A reliable and versatile asset for any MRF or plastics recycling plant.

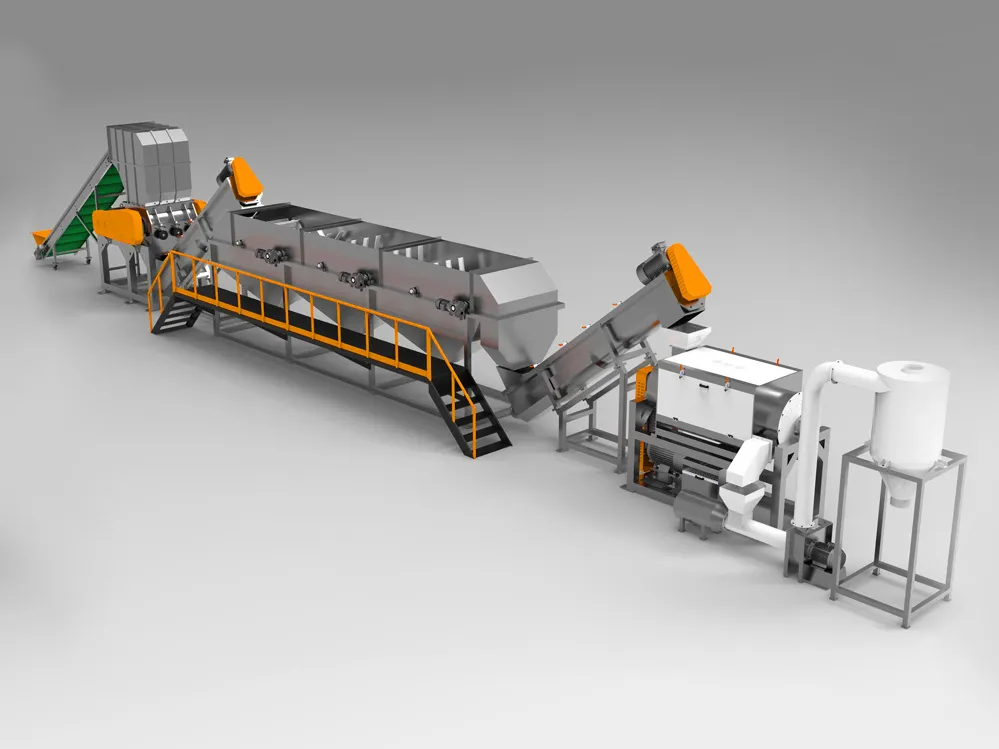

Categories Machine Video, Plastic Recycling Washing Line

Posted on

Explore our state-of-the-art PP, PE, ABS, and PS plastic recycling and washing line. Understand the step-by-step process that turns plastic waste into valuable, clean materials, supporting your eco-friendly goals and the circular economy.

Categories Plastic Recycling Washing Line

Posted on

Transform contaminated PP/PE regrind and film into valuable, high-quality reusable pellets with our advanced washing and pelletising line. Our system offers efficient cleaning, separation, drying, and precision pelletising. Customisable to your specific needs.

Categories Plastic Recycling Washing Line

Posted on

Our innovative PP PE Film Shredding and Densifying Line is an advanced solution for transforming dirty or mixed plastic films into valuable, densified material, perfectly prepared for pelletizing or further processing.

Categories Plastic Recycling Washing Line

Posted on

Transform contaminated HDPE, PP, and PS rigid plastics like bottles and lumps into high-quality reusable flakes with our complete washing and recycling line. Features robust shredding, advanced washing/separation, and efficient drying systems. Capacities from 500-2000 kg/hr. Installation and support available.

Categories Plastic Recycling Washing Line

Posted on

Discover our innovative PP PE Plastic Film Shredding and Densifying Line. A complete solution for transforming contaminated film bales into high-quality, densified products ready for reuse or further processing. Standard capacities from 200 to 1,000 kg/h . Explore features and benefits.

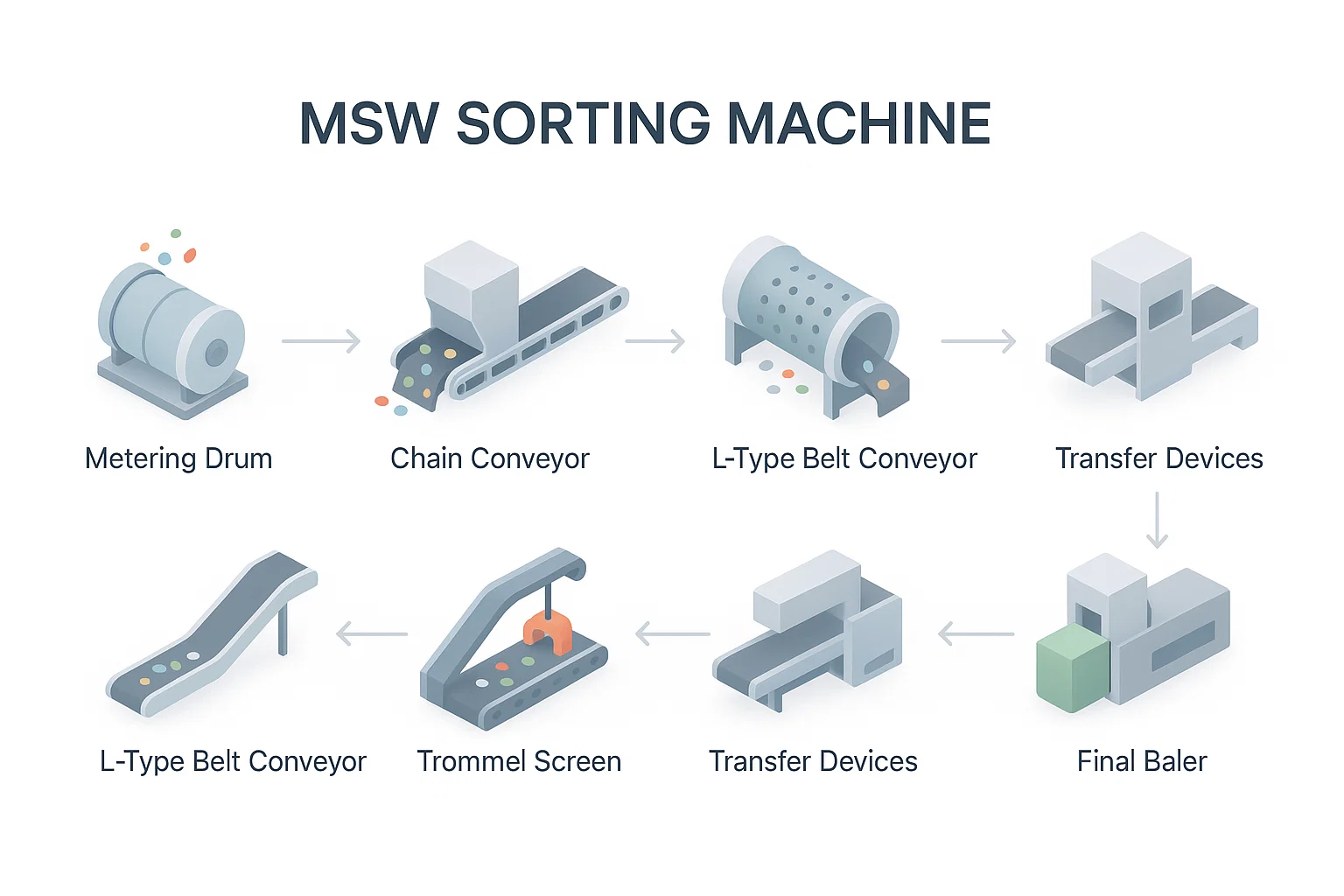

Categories MSW sorting machine

Posted on

Discover how an advanced MSW Sorting Machine processes municipal waste using a systematic flow of conveyors, screens, and separators, optimizing recycling and minimizing environmental impact.