Energycle Friction Washer: High-Efficiency Plastic Cleaning Solution

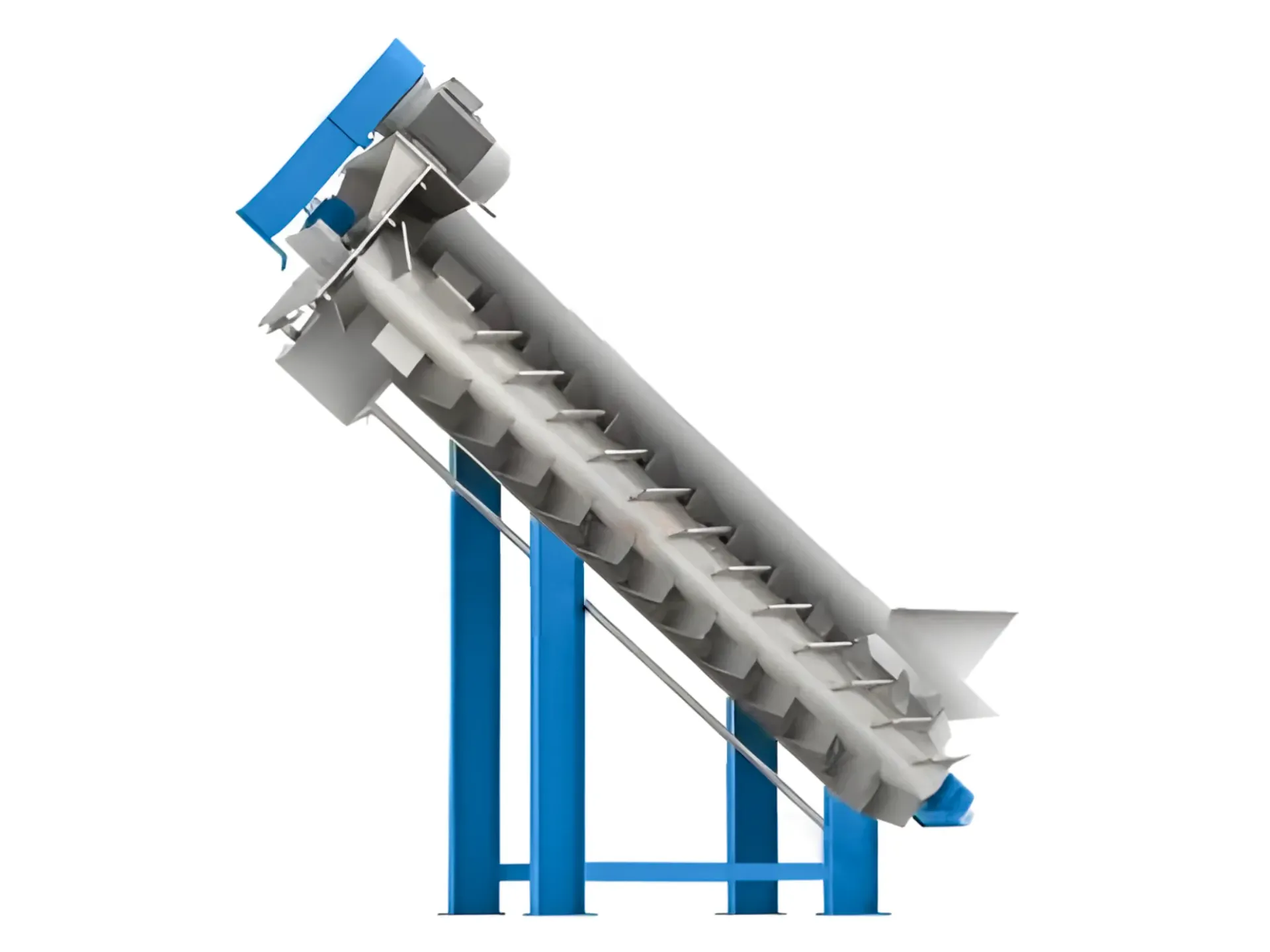

The Energycle Friction Washer is a crucial piece of equipment in the plastic recycling process, expertly designed to rigorously clean plastic materials (including films, sheets, and pellets) and effectively remove moisture. These robust cylindrical machines operate using a tilted high-speed screw, demonstrating exceptional efficiency in cleaning materials by thoroughly removing dirt, grease, and other unwanted contaminants. Fine powders and water are efficiently separated from the grinding materials by the friction washer, which is protected by a durable stainless steel screen. Raw materials are fed into the machine from the bottom, undergo intensive cleaning, and are discharged from the top outlet, ensuring a highly purified final product ready for the next stage of recycling.

Key Advantages of Energycle Friction Washers

The primary advantages of our friction washers lie in their efficient contaminant removal capabilities and low maintenance requirements. This makes them an ideal choice for businesses aiming to reduce operational costs while achieving optimal results in the plastic recycling process.

- Wear-resistant steel blades for extended operational life.

- Dynamically balanced rotors ensure smooth and stable performance.

- Isolated bearing housings to prevent water ingress and ensure durability even under harsh working conditions.

Working Principle

The Energycle Friction Screw Washer Machine houses a rotor within, adorned with many slanted paddles. As this rotor spins at a high speed, typically ranging between 500-600 RPM, it causes the plastic stream inside to scrub against each other vigorously. During this intense friction process, water is continuously sprayed through the filter nets (dewatering screen). This leads to the complete separation and removal of soil, sand, paper labels, and other contaminants from the plastic materials. The inclined frame assists in the material flow and water drainage.

Features

- Dynamically balanced rotor: Ensuring robust and reliable performance.

- Bag-type screen: Integrated on the drum sidewall enhances drying and cleaning efficiency.

- Heavy-duty welded steel structure: Offering exceptional durability.

- Isolated bearing housing: Design effectively prevents water ingress into the bearings.

- Replaceable rotor & paddles: Simplifying maintenance and reducing downtime.

- High-efficiency cleaning: High-friction effect ensures thorough washing.

- Water-saving design: Optimized water injection manifold reduces consumption.

- Supports batch processing: Improving operational efficiency.

Technical Specifications

| Model | Motor Power (kW) | Rotor Diameter (mm) | Rotor Speed (RPM) |

|---|---|---|---|

| LX-400 | 11 | 400 | 520 |

| LX-450 | 15 | 450 | 520 |

| LX-550 | 22 | 500 | 520 |

All models are crafted from high-quality SUS304 material, ensuring durability and long-term use. Moreover, they are available with CE certification. Larger, more powerful models are available based on your specific requirements – please inquire for details.

Applications in Plastic Recycling

- ✔Effectively removes contaminants such as dirt, oils, and paper from plastic flakes and films, ensuring the production of high-quality recycled products.

- ✔Removes water from the surface of plastic flakes and granules, enhancing material purity and boosting the efficiency of subsequent processing stages like drying and pelletizing.

- ✔Clean and pre-conditioned materials improve the performance and longevity of downstream recycling equipment, optimizing the overall recycling process.

- ✔Essential for facilities committed to sustainability, enabling the efficient reuse of plastics and supporting participation in the circular economy.

- ✔Helps businesses produce high-quality recycled plastics that meet industry standards, contributing to sustainable packaging and manufacturing practices.

The Energycle Friction Screw Washer Machine is an epitome of how a simple principle of friction can be harnessed to achieve clean, contamination-free plastic material, ready for further processing or recycling. Its design ensures not only effective cleaning but also a significant reduction in manual labor and time involved in the cleaning process of plastic materials. Investing in an Energycle Friction Screw Washer Machine can significantly upscale the efficiency and quality of your plastic recycling operation.

Inquire Now

To get the latest prices, lead times, or request custom specifications, send us a message using the form below.

[…] Screw Conveyor 2 […]

[…] Friction Washer Specifications […]

[…] Friction washers: Provide intensive cleaning to eliminate stubborn dirt, oils, and adhesives. […]

[…] Friction Washer: This high-efficiency cold water washing unit employs mechanical friction to vigorously scrub and remove any persistent dirt and debris from the PET flakes, ensuring a thoroughly cleaned product. […]

[…] Friction Washer […]