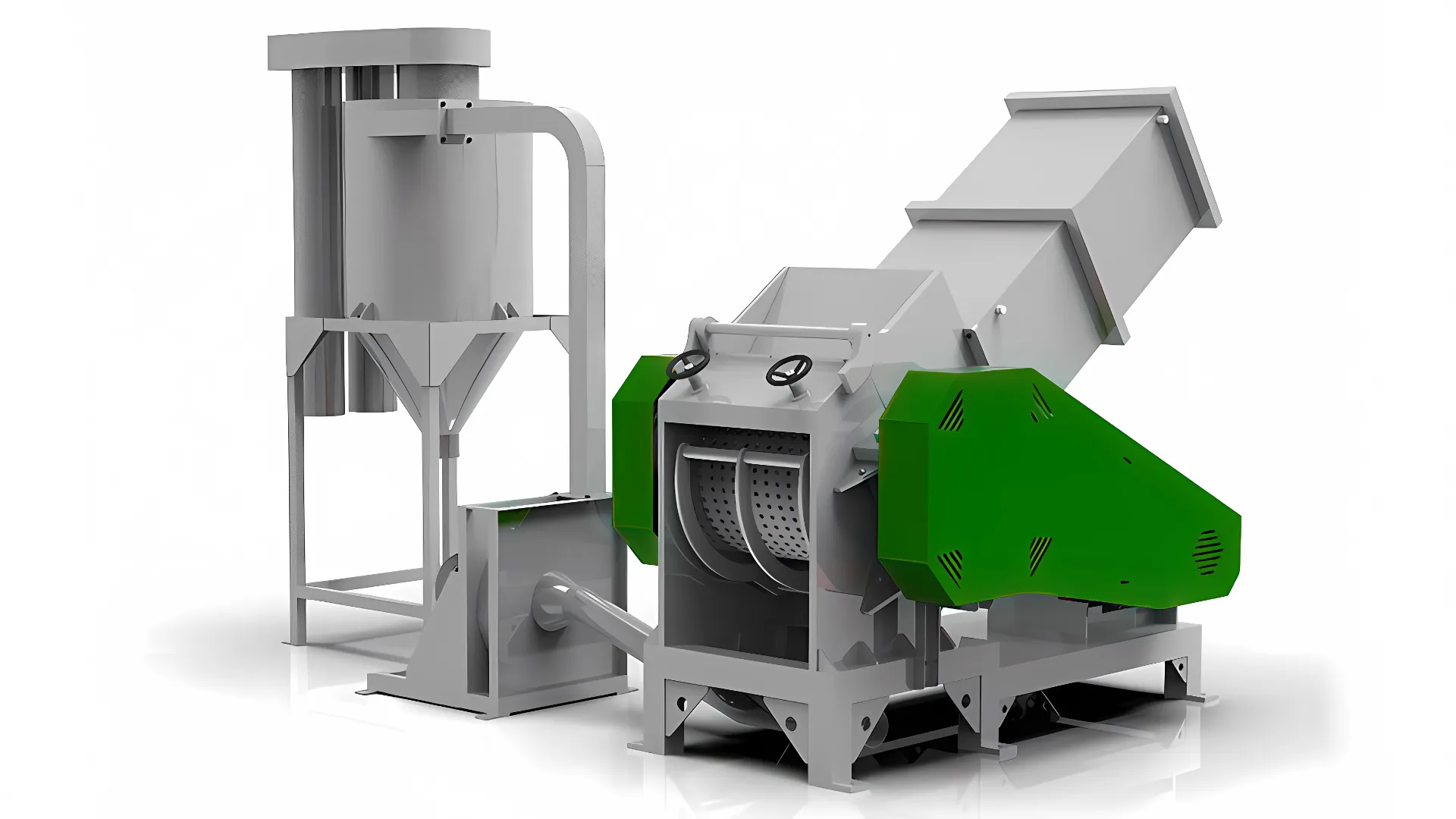

Heavy-Duty Horizontal PVC Pipe Crusher

Efficient Volume Reduction for PVC Pipe Recycling

Dealing with bulky PVC pipe scrap can be a major headache for recycling operations. Our heavy-duty horizontal PVC pipe crusher is engineered to efficiently reduce the volume of your PVC pipe waste, simplifying downstream processing and boosting your recycling efficiency.

Key Features

Conquer Any PVC Pipe

This powerful crusher effortlessly handles a wide range of PVC pipe sizes and wall thicknesses, transforming them into manageable pieces for further processing.

Built for Demanding Environments

Robust Construction: Crafted from high-grade steel, our crusher boasts exceptional durability and resistance to wear and tear, ensuring long-lasting performance in demanding recycling environments.

Horizontal Design Advantage

The horizontal configuration allows for easy feeding of long pipe sections and optimizes material flow for continuous operation.

Benefits That Make a Difference

- Increased Efficiency: Significantly reduce the volume of PVC pipe scrap, optimizing storage space and streamlining downstream processes.

- Enhanced Safety: Eliminate the hazards associated with manually handling large, unwieldy pipe sections.

- Cost Savings: Minimize transportation and storage costs by reducing the volume of your PVC scrap.

- Versatile Applications: Ideal for a wide range of applications, including PVC pipe recycling, construction and demolition waste processing, and more.

Technical Specifications

| Model | Power (kW) | Speed (rpm) | Extrusion Capacity (kg/h) | Screw Diameter (mm) | Driving Power (kW) | Heating Power (kW) | Hopper Volume (m³) | Output (kg/h) |

|---|---|---|---|---|---|---|---|---|

| ERMHC560/630 | 22/37 | 2/4 | 10/10 | 500/550 | 0.37/0.37 | 3/4 | 0.3/0.5 | 250/350 |

| ERMHC730/830 | 55/75 | 4/4 | 10/10 | 600/800 | 0.37/0.55 | 5.5/11 | 0.5/1 | 450/700 |

| ERMHC1000/1300 | 90/110 | 4/6 | 10/10 | 900/1200 | 0.75/1 | 5/18.5 | 1/2 | 850/1200 |

Applications

Recycling Plants

Used primarily in plastic recycling facilities to break down large PVC pipes into smaller pieces that are easier to handle and process.

Manufacturing Waste Management

Helps manage and recycle production waste in factories that produce PVC pipes, reducing waste and promoting sustainability.

Material Recovery Facilities

Plays a crucial role in sorting and processing waste in facilities that handle multiple types of recyclable materials.

Warranty & Support

All machines and parts to be free from defect for 1 year.

Contact us today to learn more about how we can customize a solution to meet your specific needs and help you achieve optimal efficiency and profitability.

[…] maintenance is essential for ensuring the long-term efficiency, reliability, and safety of PVC crushers . Regular maintenance can prevent breakdowns, reduce downtime, and extend the lifespan of the […]