Plasztikus granuláló gépek: Hatékony újrahasznosítás útmutatója

Műanyag pelletizáló gépek A végleges, kritikus lépés a legtöbb műanyag visszanyerési vonalban, ahol a tisztított műanyag szilánkokat egyenletes, magas értékű granulátumokká alakítják, amelyek már készülékgyártásra használhatók. A visszanyerési és gyártási szektorokban működő vállalkozások számára ez a technológia megértése alapvető az hatékonyság, a minőség és a nyereségesség eléréséhez. Ezek a gépek nem egyszerűen hulladékkezelésre szolgálnak; gyártási eszközök, amelyek alapanyagokat hoznak létre a zárt körű gazdaság számára.

Ez az útmutató bemutatja a műanyag granulátorok működését, részletezi a különböző rendszerek elérhetőségét, és kiemeli azokat a fontos tényezőket, amelyeket figyelembe kell venni az eszköz kiválasztásakor. A(z) Energycle gép, cég olyan megoldásokat épít, amelyek megfelelnek az anyagainak és működési céljaitok specifikus igényeinek.

Mi az a műanyag pelletizáló gép?

A műanyag granulátor, más néven granulátor, egy extruder-alapú rendszer, amely a feldolgozott műanyagot olvad, szűri és egyenletes méretű granulátumokra vágja. Fontos megkülönböztetni azt a szalagvágót vagy darálótól, amely a nyers műanyag hulladék előzetes méretcsökkentését végzi. A granulátor a már darált és mossza műanyag szilánkokat újrakeveri egy sűrű, könnyen kezelhető formátumba.

Ezek a végleges granulátumok egyenletes alakú, méretű és tömegtömegűek, ideálisak a gyártási berendezések, mint például az injekciós formázók és a fújásos formázók bevezetésére.

A Lényeges Eljárás: Hogyan Működik a Granulátor

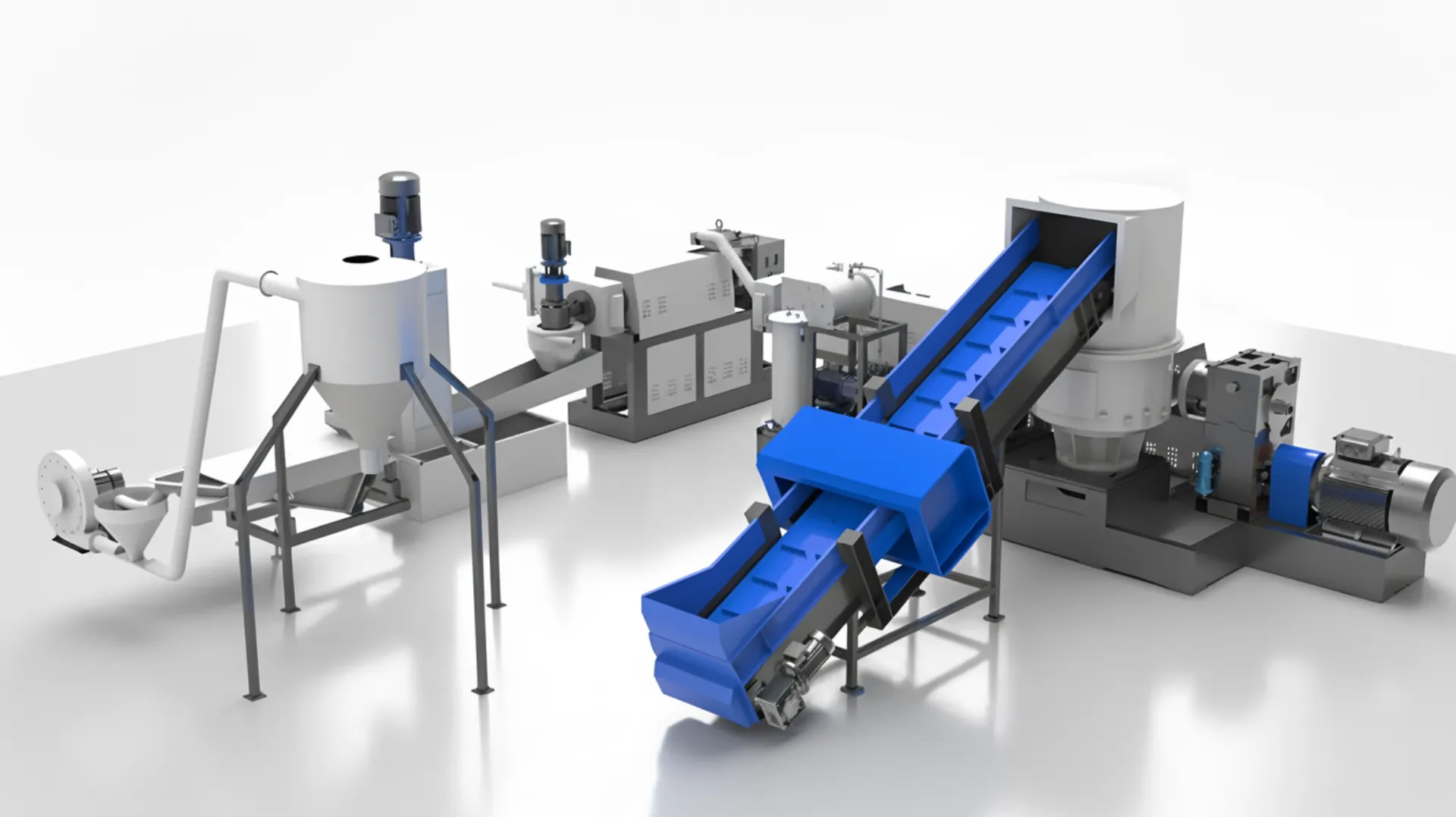

A műanyag granulálási folyamat egy többfázisú művelet, amely egy tiszta és homogén végterméket hoz létre. Bár a gépek tervezése változhat, a alapvető lépések megegyeznek:

- Táplálás: Tiszta, száraz műanyag szilánkokat egy hordóból a szivattyúba adnak. Az egyenletes adagolási sebesség elengedhetetlen a stabil kimenet érdekében.

- Olvasztás és Homogenizálás: A tartályban egy forgó szivattyú a anyagot előre tolja. A tartályon elhelyezett fűtők az anyagot olvadnak, és a szivattyú széregző hatása egyenletes olvadott állapotba keveri.

- Filtráció és degázás: A lágyított műanyag egy szűrőcsere eszközön halad keresztül, amely egy szűrőrendszer, amely eltávolítja az esetleges maradék fizikai szennyeződéseket, mint például fa, papír vagy nem olvadott részecskék. Az extruder tartályon található szívócellás degázó régió pedig eltávolítja a zárt nedvességet és a volatilis gázokat, ami kritikus a buborékok és hibák megelőzése szempontjából a végső granulátumokban.

- Vágás: A szűrt, lágyított műanyag egy számos kicsi lyukkal rendelkező die lapáton extrudálódik. Ezután egy vágórendszer vágja le a kialakuló műanyag szálakat granulátumokká. A használt vágórendszer típusa az egyik fő különbség a granuláló gépek között.

- Hűtés és szárítás: A frissen vágott granulátumok azonnal lehűtődnek, általában vízzel, hogy megszilárdítsák alakjukat. Ezután víztelenítve és szárítva kerülnek összegyűjtésre csomagolás vagy tárolás céljából.

A legfontosabb műanyag granuláló rendszerek típusai

A megfelelő granuláló rendszer kiválasztása jelentősen függ a műanyag típusától, állapotától és a szükséges gyártási kapacitástól. Íme a leggyakoribb konfigurációk:

Strand Pelletizers

Ebben a rendszerben a lágyított műanyag hosszú, tésztagolyós szálak formájában extrudálódik. Ezek a szálak egy vízforráson keresztül húzódnak át, hogy lehűtsék őket, majd egy külön vágóeszközbe (a granulálóba) kerülnek, amely darabolja őket rövid, kúpos granulátumokká.

- Legjobb: Széles körű thermoplastikus műanyagokhoz, laboratóriumi méretű gyártáshoz és olyan műveletekhez, ahol az első költség a legfontosabb.

- Megfontolások: Több helyet igényel és operátor felügyeletét, mivel a szálak a folyamat során megszakadhatnak, ami leállítja a gyártást.

Vízgyűrűs granuláló gépek

A vágás közvetlenül a die felületén történik. Amikor a műanyag kijön a die-ből, egy forgó vágófélkör vonul át a felületen, és a granulátumokat vágja. Egy folyóvízű kör azonnal fogja és lehűti a granulátumokat, majd szállítja őket a szárítóhoz.

- Legjobb: Polipropilén (PP) és polietilén (PE) polioléfinok, különösen filmből vagy zacskóból származó hulladékból. Jó egyensúlyt kínál az automatizáltság és a költség között.

- Megfontolások: Nem alkalmas olyan anyagokra, amelyek nagyon törékenyek vagy ragadósak.

Ásványvíz alatti granulátorok (UWP)

Ez egy erősen automatizált rendszer, ahol a vágófej teljesen ásványvízben átitatott kamrában van, amely a die lapra nyomódik. A granulátumok azonnal vágódnak és szilárdulnak.

- Legjobb: Nagy mennyiségű gyártás és érzékeny vagy alacsony viszkozitású műanyagok, mint például a PET feldolgozása. Nagyon egyenletes, gömbölyded granulátumokat állít elő.

- Megfontolások: Nagyobb kezdeti befektetés és bonyolultabb működtetés és karbantartás más rendszerekhez képest.

Fedezze fel a Plasztikus Granulátoraink Megoldásait

A szálaktól a vízkörös rendszerekig, granulátoraink tartósságot és teljesítményt biztosítanak. Találja meg a tökéletes gépet, amely megfelel az Ön specifikus műanyag újrahasznosítási igényeinek és gyártási céljainak.

Nézze meg a ModelljeinketAlkalmazási területek a hulladékplasztikai granulátumok számára

A plástiktömlőgépek kimenete multifunkcionális alapanyag, amely számos iparágban használják. Ezek a granulátumok minősége közvetlenül befolyásolja a végső termék minőségét.

- Csomagolás: Új palackok, tartályok, filmek és táskák gyártása.

- Autóipar: Nem kritikus alkatrészek, mint például ütközők, műszerfalak, belső burkolatok és kereklapok gyártása.

- Építés: Kombinált fa, csövek, burkolatok és hőszigetelés gyártása.

- Fogyasztási cikkek: Bútorok, konténerek, játékok és háztartási cikkek készítése.

A megfelelő granulátortömlő kiválasztása működéséhez

A megfelelő gép kiválasztása nem csupán a típus választásáról szól. Értékelnie kell a specifikus működési környezetét:

- Anyagtípus: Milyen műanyagot dolgoz fel (pl. merev HDPE, rugalmas LDPE film, PET)? Az anyag Olvadási áramlási indexe (MFI) és jellemzői meghatározzák a legjobb szivattyútervezést és vágórendszert.

- Szennyezettségi szint: Mennyire tiszta az inputanyag? A masszív szűrés és degázolás szükségessége az előzőlegi mosás és szortírozási vonal hatékonyságától függ.

- Szükséges átviteli sebesség: Milyen kilogramokban vagy fontokban szeretné megadni az órában szükséges kapacitást? Ez meghatározza a szükséges gép méretét és motor teljesítményét.

- Kívánt granulátum minősége: Kiváló minőségű granulátumot szeretne előállítani prémium alkalmazásokhoz vagy általános felhasználásra? A szükséges egységesesség és tisztaság befolyásolja a rendszer választását, mint például a szál vagy víz alatti granulátorok között.

Egy jól kiválasztott műanyag granuláló gép megbízható növekedési motor, amely alacsony értékű hulladékot átalakít egy állandó, jövedelmező termékbe. A technológia gondos megfeleltetésével a anyagának és üzleti céljainak, építhet egy rugalmas és fenntartható működést. További olvasmányok az ipari technológiákról a következő kiadványokban találhatók: Műanyagtechnológia amelyek mély technikai forrásokat kínálnak.