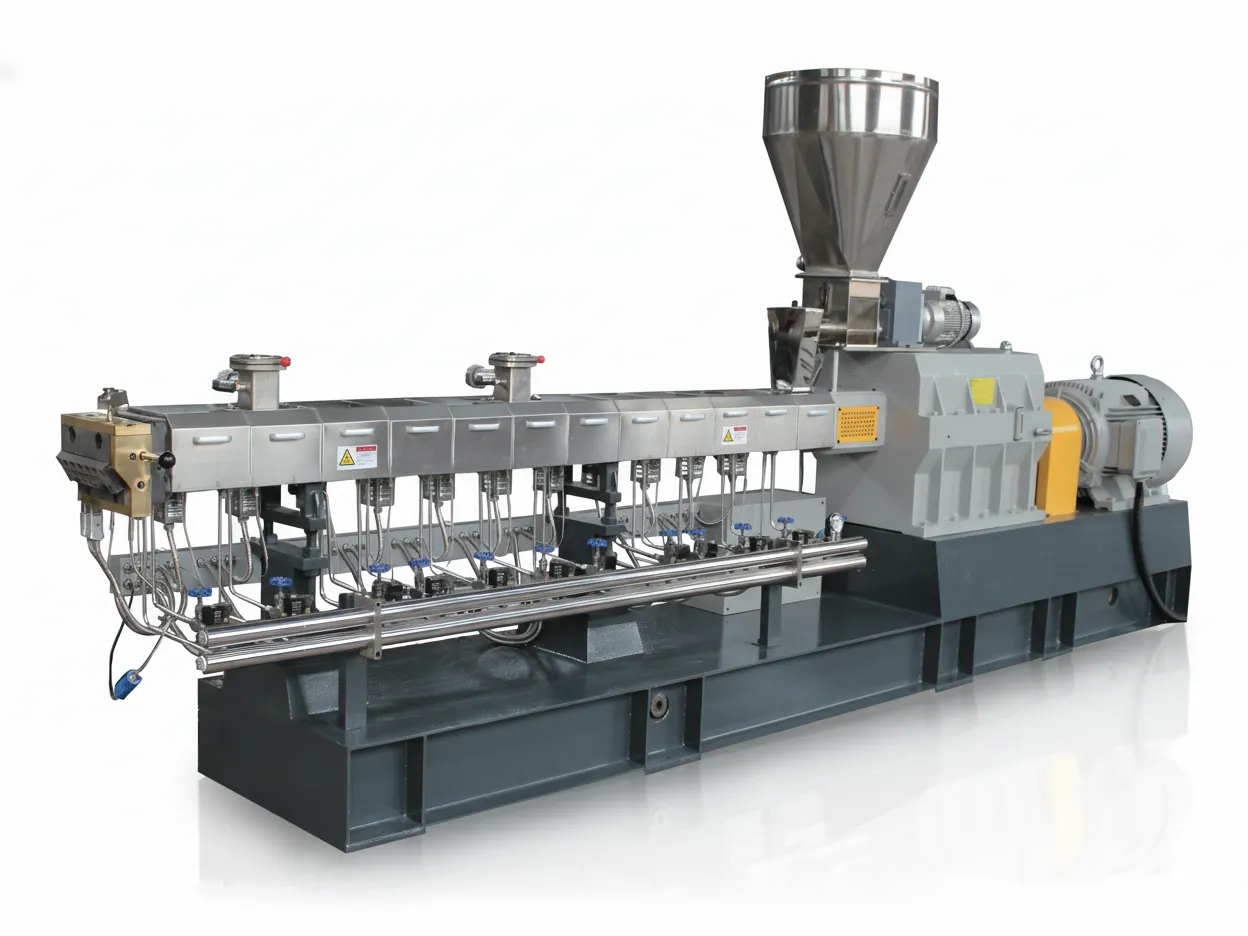

Twin-Screw Plastic Extruder & Pelletizer

Master complex compounding with our high-speed, co-rotating twin-screw extruder. Engineered for superior mixing of fillers, fibers, and additives.

Advanced Compounding Technology

Our extruder is built to handle the most demanding jobs, delivering unparalleled reliability, efficiency, and pellet quality.

Superior Compounding & Mixing

Co-rotating screw shafts provide intense, homogenous blending of plastics, fillers, and additives for a perfect compound.

Controle preciso de temperatura

Patented Heat Wave Stabilization™ technology ensures even heat distribution for an ideal, stable pelletizing process.

Continuous, Uninterrupted Operation

A hydraulic screen changer allows for filter changes without stopping the machine, maximizing uptime and throughput.

Robust & Wear-Resistant

Constructed from blended steel strengthened with gas nitriding technology for exceptional durability and long service life.

Solve Your Most Complex Compounding Challenges

Standard extruders fail when processing complex material blends. Our twin-screw system is engineered specifically for these demanding tasks.

Problem: Inconsistent Mixing

Single-screw extruders struggle to evenly disperse high levels of fillers, fibers, or masterbatch, leading to inconsistent, low-quality products.

Solution: Homogenous Blending

The intense shearing and mixing action of the co-rotating twin screws guarantees a perfectly homogenous melt, even with high additive content.

Problem: Material Degradation

Poor temperature control and localized overheating in standard extruders can degrade heat-sensitive polymers and additives, ruining the batch.

The Advanced Compounding & Pelletizing Process

A systematic process that ensures superior mixing, stable extrusion, and the creation of high-quality, uniform pellets.

1. Precision Feeding

Plastic resin, along with fillers, reinforcing fibers, and other additives, are accurately dosed into the extruder.

2. Intense Mixing & Melting

The co-rotating screws convey, shear, and intensely mix the materials while our stabilization tech ensures a perfect, even melt.

3. Melt Filtration

The homogenous molten plastic is forced through a hydraulic screen changer to remove any contaminants before pelletizing.

4. Pelletizing & Cooling

The clean melt is extruded and cut into uniform pellets using either a strand or water-ring pelletizing system, then rapidly cooled.

Vitrine de máquinas

The Ultimate Machine for High-Value Applications

Our twin-screw extruder is essential for creating the high-quality compounds and masterbatches required by advanced manufacturing sectors.

Masterbatch Production

Ideal for producing high-concentration color, additive, and filler masterbatches with perfect pigment and additive dispersion.

Polymer Compounding & Alloying

Expertly blends different polymers or compounds plastics with reinforcing agents like glass fiber, talc, and calcium carbonate.

Reactive Extrusion

Provides the controlled environment necessary for polymerization and other chemical reactions to occur directly within the extruder.

Especificações técnicas

| Modelo | Diâmetro do parafuso (mm) | Razão L/D | Driving Motor (KW) | Output (KG/H) |

|---|---|---|---|---|

| SHJ50/RM120 | 50.2 / 120 | 24/48, 7/20 | 37-45 / 30-37 | 150-300 |

| SHJ75/RM150 | 62.4 / 150 | 24/48, 7/20 | 55-75 / 37-45 | 150-300 |

| SHJ75/RM180 | 71 / 180 | 24/48, 7/20 | 90-110 / 45-55 | 300-600 |

| SHJ95/RM200 | 93 / 200 | 24/48, 7/20 | 132-135 / 55-75 | 500-1,000 |

Perguntas frequentes

O que é a principal vantagem de um extrusor de duplo eixo em comparação com um extrusor de eixo único?

Um extrusor de duplo eixo oferece capacidades de mistura e compounding muito superiores. Os eixos de rosca co-rotativos criam uma mistura intensa e distributiva, o que é essencial para combinar diferentes materiais, como polímeros com preenchedores, fibras ou corantes. Um extrusor de eixo único é mais adequado para a extrusão simples de um material pré-composto.

O que é a tecnologia “Heat Wave Stabilization™”?

É nossa tecnologia patenteada que garante uma distribuição de calor precisa e uniforme por todo o barril do extrusor. Isso previne pontos quentes e frios, o que é crítico para o processamento de materiais sensíveis ao calor e para garantir uma viscosidade de mistura consistente, resultando em uma qualidade superior e pelotas mais uniformes.

Pode esta máquina ser personalizada para minhas necessidades específicas?

Sim. O sistema é altamente modular. Você pode escolher diferentes métodos de pelotização, como “pelotização de corda” ou “pelotização de mistura/anel de água”. Também podemos adicionar componentes como tanques de água, máquinas de desidratação e silos de produto para criar uma linha de produção automatizada completa, adaptada às suas necessidades.

Elevate Your Compounding Capabilities

Stop struggling with inconsistent blends and material degradation. Contact us to learn how our twin-screw extruder can revolutionize your production process. Get a custom quote today.