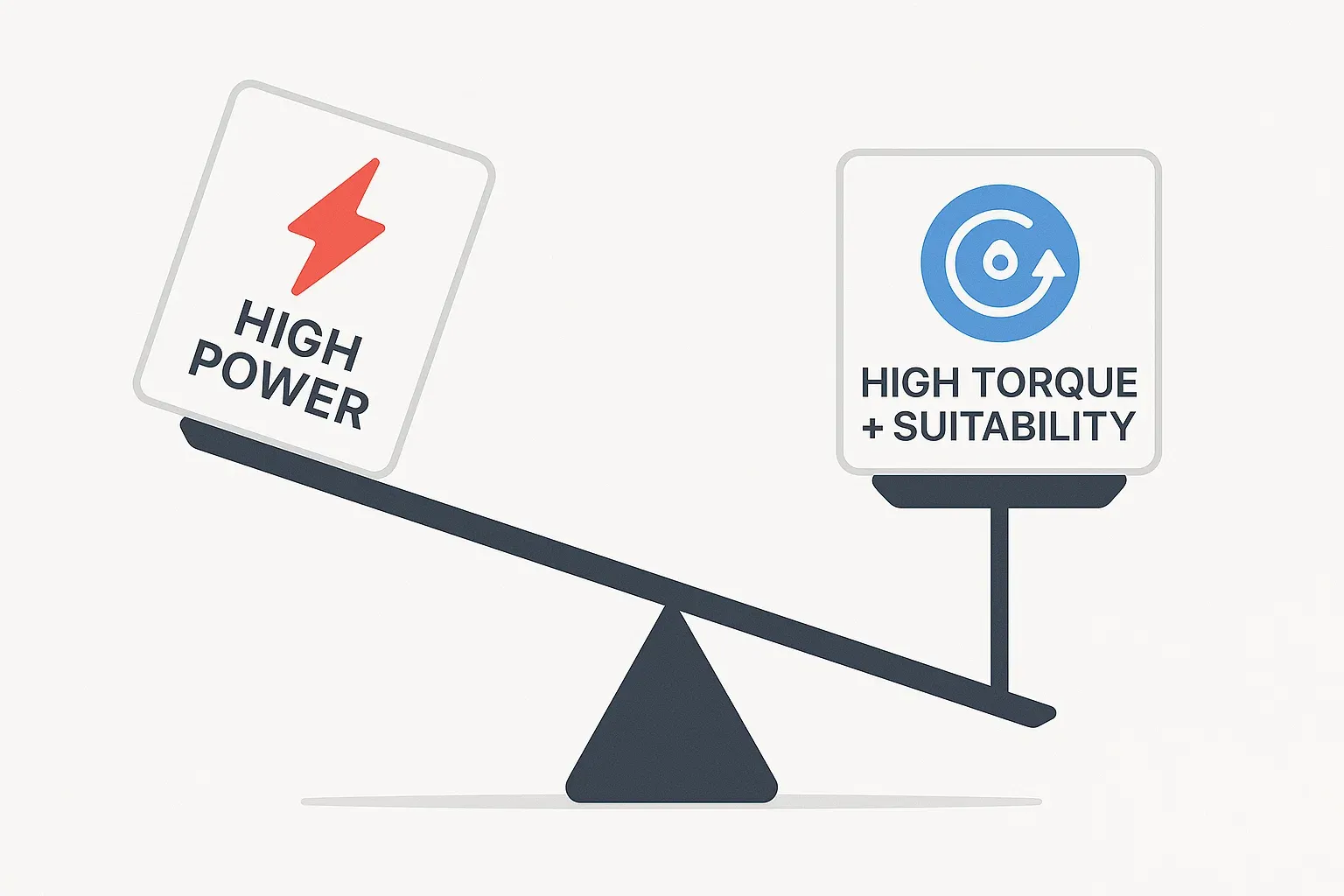

In the world of industrial recycling and waste management, selecting the right shredder is a critical decision that directly impacts operational efficiency, cost-effectiveness, and the quality of the final processed material. A common misconception often leads businesses astray: the belief that a higher-power motor invariably equates to a better, more capable shredder. However, this “bigger is better” philosophy is a significant oversimplification. The reality is far more nuanced. Welcome to the principle of ‘right-sizing’, a philosophy we at Energycle Machine champion to ensure our clients receive the most effective and economical solution for their specific needs.

This comprehensive guide will debunk the pervasive myth about shredder power. We will explore the intricate relationship between power, torque, and processing capability, and introduce the “suitability principle” as the cornerstone of intelligent shredder selection. Whether you are a manufacturer dealing with production scrap, a large-scale recycling facility, or a professional buyer of industrial equipment, understanding these fundamentals will empower you to make an informed investment that pays dividends for years to come.

The Power Myth: Why More Kilowatts Don’t Guarantee Performance

It is easy to see how the myth of “more power equals better performance” took hold. In many applications, from consumer electronics to vehicles, higher power figures are a key marketing metric. In the context of industrial shredders, however, motor power (measured in kilowatts, kW) is only one part of a complex equation. Focusing solely on this single metric can lead to several undesirable outcomes:

- Excessive Energy Consumption: A needlessly oversized motor will draw significantly more power than required for the application, leading to inflated electricity bills and a larger carbon footprint. In an era of rising energy costs and environmental scrutiny, this is a critical consideration for businesses in Europe and the USA.

- Unnecessary Capital Expenditure: Higher-power shredders command a higher price tag. Opting for a machine that is overpowered for your materials means a substantial upfront overspend that could have been allocated to other vital areas of your operation.

- Sub-optimal Performance: Counterintuitively, a shredder that is too powerful for the material being processed can be inefficient. It may process the material too quickly, leading to larger, inconsistent particle sizes or failing to engage correctly with lighter, more pliable waste streams.

- Increased Maintenance and Wear: An oversized motor and drivetrain can place undue stress on shredder components, particularly when processing materials that do not require such brute force. This can lead to accelerated wear and tear, more frequent downtime, and higher maintenance costs over the machine’s lifespan.

The goal is not to find the most powerful machine, but the most appropriate one. This is the essence of what we call the suitability principle.

The Suitability Principle: The Core of Smart Shredder Selection

At Energycle Machine, we guide our clients using the suitability principle. This approach moves beyond a single specification and instead focuses on a holistic analysis of your unique operational requirements. It’s about finding the perfect synergy between the machine’s capabilities and the application’s demands. To do this, we must ask the right questions. Anyone looking to understand how to choose the right shredder for their material should start with these key considerations.

1. Material Characteristics: The Most Critical Factor

The type of material you need to process is the single most important variable in shredder selection. Different materials behave in vastly different ways when subjected to the cutting and tearing forces within a shredder. Key properties to define include:

- Tipo de material: Is it plastic, wood, metal, paper, or something more specialised like textiles, carpets, or electronic waste?

- Hardness and Abrasiveness: Hard and abrasive materials (e.g., glass-filled plastics, construction debris) require robust cutting systems and slower shaft speeds to minimise wear.

- Ductility and Elasticity: Soft, elastic materials like textiles and carpets present a unique challenge. They tend to stretch and wrap around shredder shafts rather than shearing cleanly. This is where machine design, not just raw power, becomes paramount.

- Bulk Density and Form: Are you feeding bulky, hollow parts, dense bales, or loose, light materials? The shredder’s infeed hopper and cutting chamber must be designed to handle the material’s form factor effectively.

For instance, the requirements for processing dense hardwood pallets are entirely different from those for recycling post-consumer carpet tiles. The former requires high torque to break through the solid material, while the latter needs a specialised cutting system to prevent wrapping and ensure a consistent cut.

2. Throughput Requirements: How Much, How Fast?

Your desired processing volume, typically measured in tonnes per hour, is another crucial piece of the puzzle. This will influence the size of the shredder’s cutting chamber, the motor power, and the overall design of the machine. It is essential to be realistic about your current and future needs. Under-specifying will create a bottleneck in your operations, while over-specifying leads to the inefficiencies we discussed earlier. A professional shredder manufacturer like Energycle Machine can help you accurately calculate your required throughput and recommend a machine sized accordingly.

3. Desired Output Particle Size

What is the end-goal for your shredded material? Are you aiming for a rough size reduction for landfill, a specific particle size for further processing in a granulation system, or a uniform flock for use in manufacturing? The required output size will determine the type of shredder (e.g., single-shaft, dual-shaft, quad-shaft) and the size of the screen used to classify the material. Finer output sizes often require a secondary screening and recirculation process, which places different demands on the system.

Power vs. Torque: Understanding the Key Difference

This is where we address the core technical point: shredder power vs. torque. While related, they are not the same thing, and for many shredding applications, torque is the more critical factor.

- Power (kW): In simple terms, power determines how fast work can be done. A higher power motor can, under the right conditions, turn the shredder’s shafts at a higher speed or handle a greater volume of material in a given time.

- Torque (Nm): Torque is the rotational force the shredder shafts can exert. It is the raw, twisting force that allows the cutters to grab, tear, and break through tough, dense materials. High torque is essential for processing difficult items like baled textiles, thick carpets, and dense plastics.

Think of it this way: a Formula 1 car has a very high-power engine, allowing it to achieve incredible speeds. A tractor, however, has a high-torque engine, which allows it to pull heavy loads at low speeds. For many challenging shredding tasks, you need the ‘tractor’ – immense rotational force to overcome material resistance.

Energycle Machine designs its shredders with sophisticated gearboxes and drive systems that optimise the balance between power and torque. By using intelligent gear reduction, we can take the speed from a relatively standard electric motor and convert it into massive torque at the cutter shafts, ensuring even our more modestly powered machines can tackle incredibly tough materials. This is a far more efficient and effective approach than simply installing a larger motor.

A Practical Example: Textile and Carpet Shredder Selection Guide

Let’s apply these principles to a particularly challenging application: shredding textiles and carpets. This is a perfect illustration of why the suitability principle is so important.

Materials like nylon carpets, polyester fabrics, and mixed textile waste are notoriously difficult to process. They are non-friable, elastic, and have a strong tendency to wrap around rotating shafts, which can quickly bring a standard shredder to a halt. When considering how to choose a shredder for textiles, brute force is not the answer.

Key considerations for buying a carpet shredder include:

- Cutter and Counter-Knife Design: Specialised, sharp cutters with very tight tolerances are needed to ensure a clean scissor-like cut, preventing pulling and wrapping.

- Velocidade do rotor: Slower rotor speeds are often preferable as they reduce the risk of materials wrapping and melting due to friction.

- Contaminant Protection: Carpets especially can contain abrasive sand and dirt, or hard contaminants like staples and grippers. The machine needs robust shaft seals and bearings to withstand this.

- Alimentação controlada: A ram-assist system, common in single-shaft shredders, is crucial for controlling how the material is presented to the rotor, ensuring it is shredded effectively rather than just bouncing on top of the cutters.

This is where a specialised machine demonstrates its value. For example, our textile/carpet waste single-shaft shredder has been specifically engineered with these challenges in mind. It combines high-torque delivery with a purpose-built cutting chamber and material feed system to provide consistent and reliable performance on these demanding materials. A buyer focused only on finding the highest kilowatt rating would likely overlook such a specialised, and ultimately more effective, solution.

Partnering with an Expert: The Value of Professional Guidance

Making the right choice requires expertise. The complexities of material properties, machine design, and operational goals are best navigated with a partner who possesses deep industry knowledge. A reputable manufacturer will not simply sell you a machine from a catalogue; they will work with you to understand your process from start to finish.

At Energycle Machine, our process begins with a conversation. We believe that providing our equipment selection advice is one of the most valuable services we offer. We encourage prospective clients to send us material samples for testing in our facility. This allows us to provide empirical data on throughput, particle size, and the precise power and torque requirements. This data-driven approach removes guesswork and ensures the shredder we recommend is perfectly matched to your needs, guaranteeing performance and delivering the best possible return on your investment.

Perguntas Frequentes (FAQ)

1. How do I know if I need a high-torque or high-speed shredder?

This depends entirely on your material. High-torque, low-speed shredders are ideal for tough, dense, or elastic materials like plastics, wood, and textiles, as they provide the necessary force to cut and tear effectively. High-speed shredders can be suitable for lighter, more friable materials where rapid size reduction is the primary goal, but they are less common in heavy industrial applications. The best way to know for sure is to consult with an expert manufacturer like Energycle Machine.

2. Can I use one shredder for multiple different materials?

While some shredders offer a degree of versatility, a machine optimised for one material type may not perform well with another. For example, a shredder designed for brittle plastics may struggle with elastic carpets. If you need to process multiple materials, it is crucial to discuss the full range with your supplier. We can often configure a machine with features like variable speed drives and interchangeable screens to handle a broader spectrum of waste streams effectively.

3. What is the most important factor to consider besides the material itself?

After defining your material, the next most important factors are your required throughput (how many kilograms or tonnes per hour) and the desired final particle size. These three elements—material, throughput, and particle size—form the core of the suitability principle and will guide you to the correct type and size of shredder for your operation.

4. How does Energycle Machine ensure the trustworthiness and reliability of its equipment?

Our commitment to E-E-A-T (Experience, Expertise, Authoritativeness, and Trustworthiness) is at the core of our business. With years of hands-on experience in the recycling machinery industry, our team possesses deep technical expertise. We demonstrate our authoritativeness through detailed case studies, material testing, and transparent communication. Most importantly, we build trust by delivering robust, reliable machines backed by comprehensive warranties and responsive after-sales support, ensuring our clients see us as a long-term partner in their success.

Take the Next Step Towards Efficient Shredding

Choosing the right industrial shredder is a significant decision. Don’t let common myths and oversimplified metrics guide your investment. By embracing the suitability principle and focusing on the unique demands of your material and operation, you can secure a solution that is efficient, reliable, and perfectly sized for your needs.

The team at Energycle Machine is ready to provide the expert guidance you need. We invite you to leverage our technical knowledge to find the ideal shredding solution for your business.

Contact us today to discuss your requirements, schedule a material test, or request a detailed quote. Let us help you find the perfect fit, not just the biggest box.