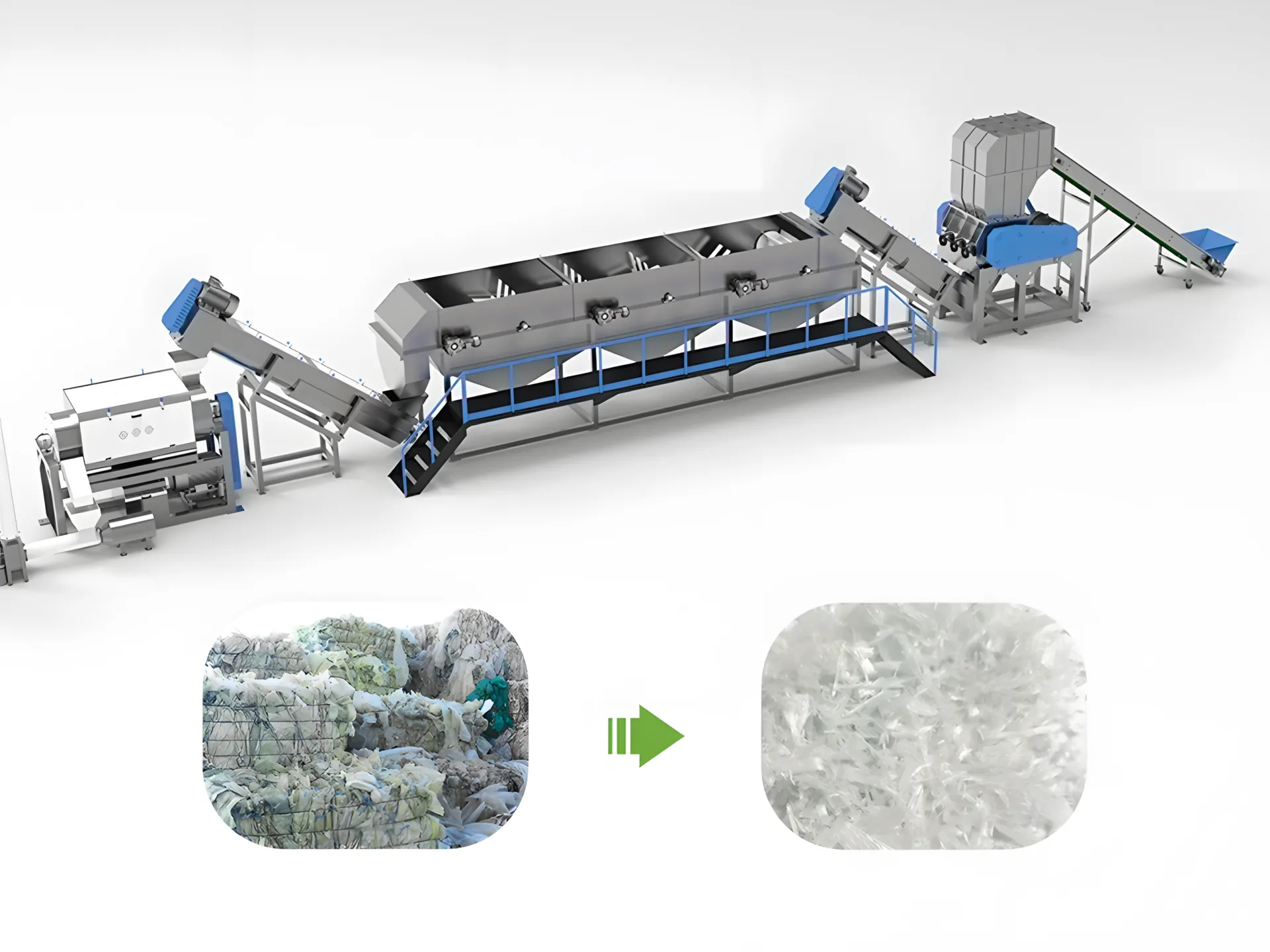

Transforme seus resíduos de filme plástico em recursos valiosos! Nossa empresa é pioneira em soluções de reciclagem de filme plástico altamente eficientes e sustentáveis. Enfrentamos o desafio ambiental dos resíduos plásticos de frente, atendendo à crescente demanda por pellets plásticos de alta qualidade. Nossa avançada linha de lavagem de filme plástico totalmente automatizada é habilmente projetada para processar polipropileno (PP), polietileno (PE) e uma ampla gama de outros tipos de filme. Projetado com máquinas estrategicamente integradas, nosso sistema maximiza a produtividade e minimiza o desperdício, garantindo um processo mais limpo e um planeta mais saudável.

Quer você esteja processando volumes moderados ou precise de recursos de reciclagem em larga escala, temos a solução certa para você. Nossa Linha de Lavagem para Reciclagem de Filmes Plásticos padrão oferece capacidades de entrada de 500 kg/h até 3.000 kg/h. Precisa de algo maior? Somos especialistas em criar sistemas personalizados, integrando máquinas adicionais e aumentando a capacidade para atender precisamente às suas demandas operacionais exclusivas.

Nossa solução completa converte perfeitamente filmes plásticos soltos ou enfardados em pellets prontos para uso. Mais do que apenas reciclagem, é um passo significativo para a redução da pegada de carbono dos resíduos plásticos. Ao optar pela reciclagem em vez de aterros sanitários, você contribui ativamente para uma economia circular, um meio ambiente mais saudável e um futuro verdadeiramente sustentável.

Somos apaixonados por sustentabilidade e comprometidos em oferecer um atendimento excepcional ao cliente. Nossa equipe experiente está ansiosa para ajudar você a encontrar a solução perfeita para seus objetivos de reciclagem de filme plástico. Pronto para causar um impacto ambiental positivo e, ao mesmo tempo, aumentar seus lucros? Entre em contato conosco hoje mesmo para saber mais sobre nosso inovador sistema turnkey!

Principais Parâmetros Técnicos

Desbloqueie a configuração de reciclagem ideal para as suas necessidades! Nós fornecemos serviços complementares de design de soluçõesNossos especialistas analisarão suas necessidades específicas e projetarão a linha de limpeza de filme plástico mais eficiente e eficaz para sua operação. Entre em contato hoje mesmo para obter mais detalhes e discutiremos seu projeto.

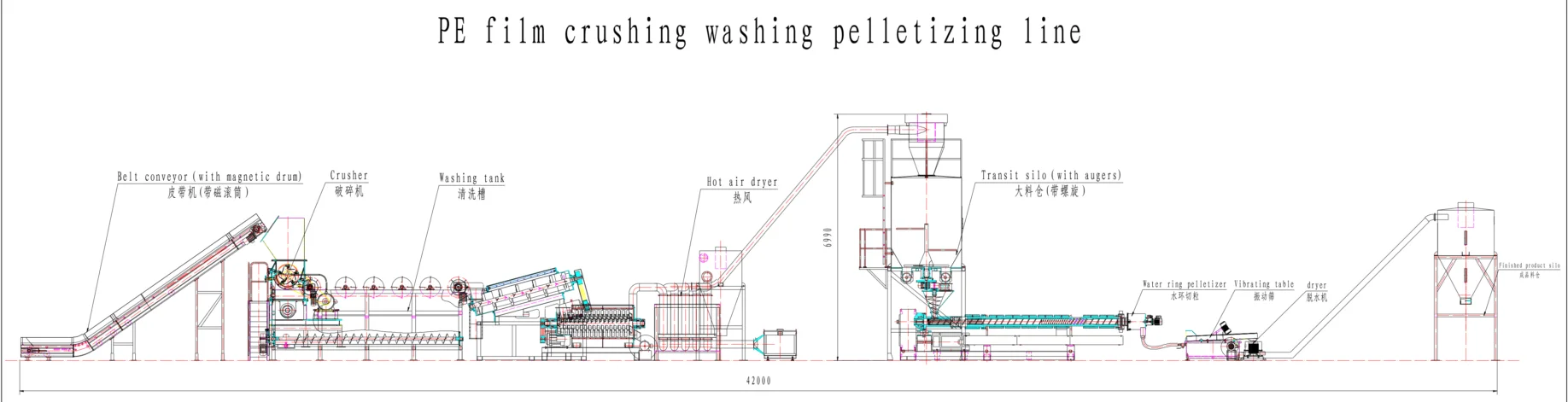

Princípio de funcionamento: passo a passo

Nossa linha de lavagem de filmes plásticos opera perfeitamente por meio de um painel de controle elétrico central e gabinete. Cada máquina é conectada de forma inteligente por transportadores, garantindo um fluxo de material uniforme e um processamento altamente eficiente do início ao fim.

- Máquina trituradora de plástico: Filmes plásticos podem se enroscar facilmente. Nosso robusto triturador resolve esse problema primeiro, cortando o filme em pedaços menores e mais fáceis de manusear (geralmente de 2,5 a 12,7 cm). Essa etapa crucial evita bloqueios posteriores e garante uma operação suave.

- Granulador de plástico (moagem úmida): O granulador reduz ainda mais o tamanho do plástico (para cerca de 10-20 mm). É importante ressaltar que este é um processo de granulação úmida. A água é introduzida aqui, proporcionando uma lavagem inicial e um pré-tratamento antes das principais etapas de limpeza.

- Arruela de fricção: Alta velocidade é fundamental aqui. Girando a quase 1.000 RPM, a lavadora de fricção utiliza uma ação de limpeza intensa para desalojar e remover contaminantes persistentes com eficácia. Ela também é excelente para quebrar papel e papelão em fibras facilmente removíveis. Para materiais excepcionalmente sujos, alguns sistemas incorporam uma segunda lavadora de fricção.

- Tanque de separação de pia-flutuação: Utilizando o princípio simples da densidade, este tanque utiliza água como meio. Películas plásticas mais leves (como PP e PE) flutuam, enquanto contaminantes mais pesados (areia, terra, vidro, metais) afundam para facilitar a remoção.

- Máquina de desidratação centrífuga: A primeira etapa crucial da secagem. Esta máquina utiliza força centrífuga para remover rapidamente a maior parte da água superficial dos flocos de plástico. Isso reduz significativamente a energia necessária para a fase de secagem térmica subsequente, reduzindo os custos operacionais.

- Máquina de desidratação por prensa helicoidal (opcional): Para uma eficiência de desidratação ainda maior, pode-se adicionar uma prensa helicoidal. Ela aplica alta pressão para extrair fisicamente a água do filme plástico. Em algumas configurações, ela pode substituir com eficácia *tanto* o desidratador centrífugo quanto os secadores térmicos.

- Secador térmico e separador ciclônico: Os flocos de plástico limpos passam por uma rede de tubos de aço inoxidável aquecidos, evaporando qualquer umidade residual. Em seguida, um separador ciclônico resfria o material com ar, preparando-o para armazenamento e, ao mesmo tempo, removendo partículas finas e poeira.

- Silo de produto: Um silo de armazenamento dedicado contém os flocos de plástico limpos e secos, prontos para a transformação final.

- Máquina de peletização de plástico: O grand finale! Os flocos de filme limpos são alimentados em nosso sistema especializado de peletização por anel de água. Esta máquina derrete, extruda e corta o plástico em pellets redondos uniformes e de alta qualidade – prontos para serem reutilizados na fabricação de novos produtos.

OBTENHA UM ORÇAMENTO E MAIS INFORMAÇÕES

Informações de garantia

Todas as nossas máquinas de reciclagem vêm com uma garantia limitada abrangente de 1 ano.

Interessado em receber os preços mais recentes e os prazos de entrega estimados? Envie-nos uma mensagem rápida usando o formulário abaixo e nossa equipe entrará em contato com você o mais breve possível!