Thin-film plastics such as LDPE films present significant handling, feeding, and transport challenges in recycling operations. Washed LDPE flakes typically have very low bulk density and high entrained air, making them inefficient to convey and expensive to ship.

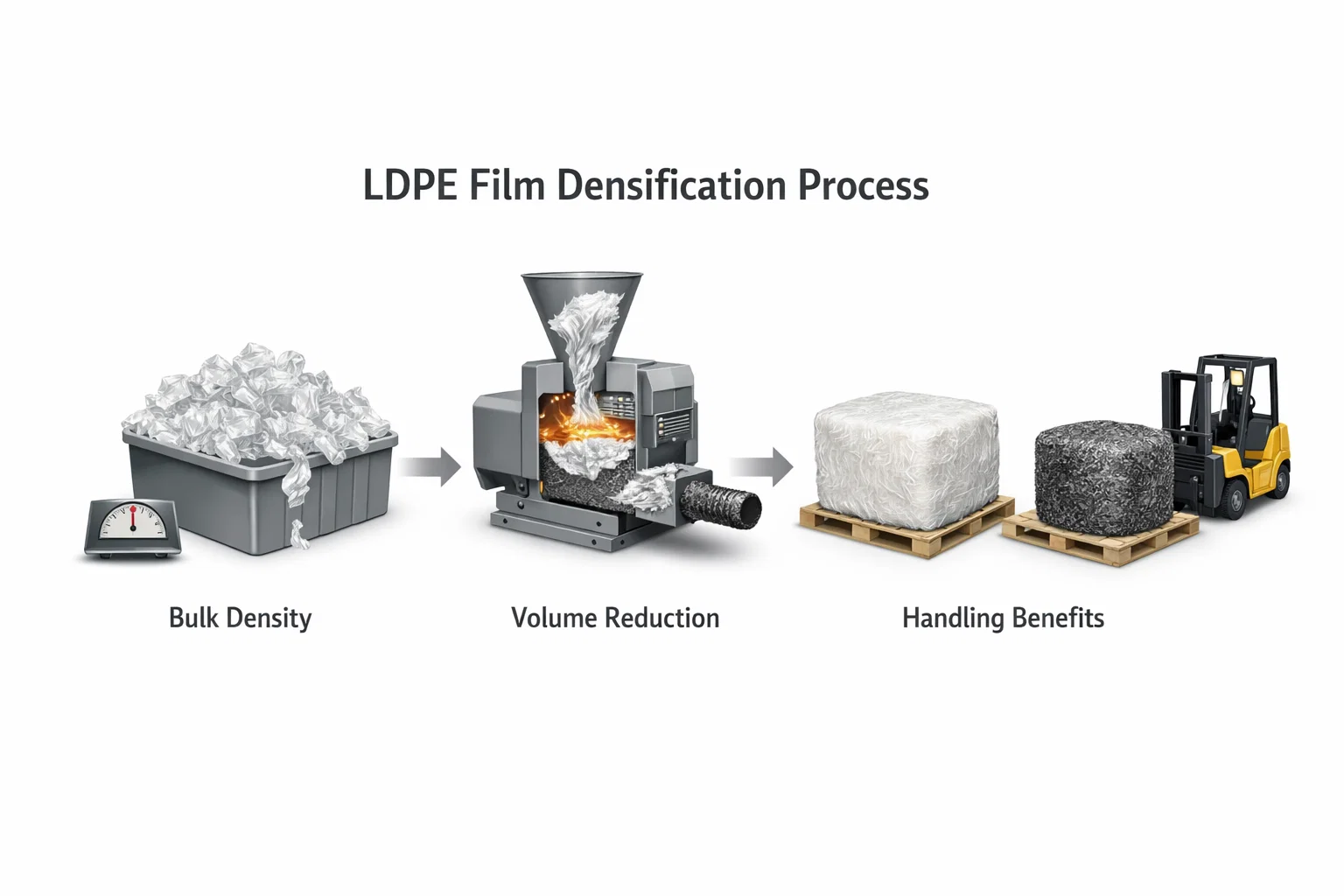

This guide explains how mechanical densification changes bulk density, reduces volume, and improves handling performance in industrial recycling contexts. It highlights physical principles, typical performance outcomes, and practical processing advantages—without focusing on specific equipment models.

What Makes Film Materials Difficult to Handle

LDPE film flakes have:

- Low bulk density — large void space and trapped air

- Poor flowability — flakes bridge and swirl rather than flow

- High volume relative to weight — inefficient use of container space

For example:

- Loose LDPE film flakes: 30–80 kg/m³

- Washed flakes with moisture: 60–120 kg/m³

At this stage, a 40’ high-cube container might be filled with only 1.5–3 tons of material, wasting logistics capacity and increasing cost.

How Densification Changes Bulk Density

Mechanical densification uses controlled compression and dewatering to restructure film flakes into compact agglomerates with higher bulk density.

The process involves:

1. Mechanical Compression

As material travels through a compression zone or screw, free water and entrained air are expelled through perforated screens, reducing total void volume.

2. Frictional Heat and Surface Softening

Mechanical work generates heat, raising LDPE temperature into the softening range (typically 70–100 °C). This softening slightly fuses surfaces and eliminates residual air pockets without melting the polymer completely.

3. Formation of Compact Agglomerates

The output is a dense, irregular agglomerate form with significantly reduced free volume and improved stability.

Typical densified bulk density ranges:

- 400–600 kg/m³ (most common)

- Up to 650–700 kg/m³ under optimized conditions

This represents roughly a 6–10× increase compared to the pre-densification state.

Volume Reduction and Its Implication for Logistics

Densification reduces the volume of LDPE film material by approximately 70–85% (6:1 to 10:1 volume reduction), which has several direct advantages:

- More efficient container loading

- Lower freight cost per ton

- Reduced number of transport cycles

Converting bulky flake loads into higher bulk density agglomerates allows transportation to be limited by weight rather than volume—an essential cost lever for global recycling logistics.

Improved Feeding and Process Stability

Low-density film flakes often cause:

- Freelancing and bridging in hoppers

- Surging or starvation in extruders

- Inconsistent melt flow

After densification the material:

- Flows more consistently

- Reduces bridging and fluffing

- Provides more stable input for downstream equipment

This improves efficiency, reduces downtime, and enhances overall recycling throughput.

Energy Considerations Compared to Thermal Drying

Mechanical densification offers advantages over thermal drying:

- Nižší spotřeba energie

- Reduced thermal degradation risk

- Residual compressive heat pre-heats material

- No need for large drying ovens or heat sources

These benefits make mechanical densification attractive for recycling facilities aiming to optimize total process energy use.

Distinguishing Bulk Density from True Material Density

It’s important to differentiate:

- Bulk density — mass per unit volume including voids (important for logistics and feeding)

- True density — intrinsic polymer density (LDPE ≈ 0.91–0.93 g/cm³)

Mechanical densification increases objemová hustota, not true polymer density. The material remains below true density unless fully melted and pelletized.

When Densification Is Especially Beneficial

Film densification delivers value in contexts where:

- Transportation cost dominates recycling economics

- Feedstock variability inhibits stable extrusion

- Space constraints limit storage or material staging

- Feeding consistency is essential for downstream process reliability

Practical Equipment Considerations

Many recycling operations use mechanical compression and dewatering systems as part of their film preparation lines. When reviewing process alternatives, it’s useful to consider system power, throughput capacity, screen area, and maintenance requirements.

For facilities exploring industrial solutions for plastic film squeezing and dewatering, you may refer to dedicated equipment options here:

(Note: the above link provides equipment context; this article focuses on the process benefits.)

Závěr

For LDPE film recycling lines, mechanical densification significantly improves bulk density, reduces transport costs, and stabilizes material feeding. By understanding how bulk density changes before and after densification—and how material behavior changes in logistics and downstream processing—recycling operations can make better engineering decisions and achieve more consistent production outcomes.