Looking to maximize efficiency and quality in your polymer processing operations? Energycle Delivers cutting-edge korotirajući ekstruderi s dva puža technology engineered for precision compounding, mixing, and processing across plastics, chemicals, food production, and advanced materials. With proven expertise in extrusion technology and a customer-first approach, we assist manufacturers worldwide in achieving superior production outcomes.

What Is a Co-Rotating Twin Screw Extruder?

A co-rotating twin screw extruder is equipped with two intermeshing screws that rotate in the same direction within a heated barrel. This closely intermeshing design ensures exceptional self-wiping action and uniform material distribution, making it the industry standard for complex compounding applications.

Key advantages include:

- Superior mixing capability – Both distributive and dispersive mixing ensure homogeneous blending of polymers, additives, fillers, and reinforcements

- Excellent self-cleaning – Co-rotating intermeshing screws prevent material buildup and reduce the risk of degradation

- Flexible processing – Modular screw design adapts to diverse materials and formulations

- Efficient devolatilization – Multiple venting zones effectively remove moisture and volatiles

Why Choose Energycle Co-Rotating Twin Screw Extruders?

1. Versatile Applications Across Multiple Industries

Our twin screw extruders excel in demanding production environments:

- Plastics compounding – Masterbatch production, polymer blends, filled compounds

- Chemical processing – Réactivité d'extrusion, modification des polymères, dispersion d'additifs

- Revêtements en poudre – Mélange uniforme de pigment et de résine

- Transformation alimentaire – Produits de snacks, alimentation pour animaux, protéines texturées

- Composites bois-plastique (WPC) – Dalles, profils, matériaux de construction

- Applications pharmaceutiques – Extrusion à fusion thermique pour systèmes de libération de médicaments

2. Ingénierie avancée et conception modulaire

Modular “Building Block” Screw Configuration

Energycle extruders are equipped with interchangeable screw elements, allowing for customization to meet your specific process requirements. This versatility offers:

- Easy adaptation to new formulations without the need for equipment replacement

- Simplified maintenance and expedited changeovers

- Optimized processing for every unique application

- Cost-effective process development and scaling

RTM Series Performance Range

Our extensive product range includes screw diameters from 20mm to 200mm, with configurations designed to cater to your throughput requirements:

- Laboratory Scale (20-35mm) – Research and Development, pilot testing, small-batch production

- Production Scale (50-200mm) – Industrial-scale manufacturing with outputs reaching several tons per hour

- Customized Torque Classes – Tailor motor power and gearbox design to material viscosity and processing intensity

3. Superior Plasticizing & Compounding Performance

The closely intermeshing screw geometry ensures:

- Complete self-cleaning action – Screws continuously clean each other, thereby preventing material stagnation

- Positive conveying – Consistent material flow irrespective of viscosity changes

- Intensified Mixing Zones – Kneading blocks and mixing elements ensure thorough dispersion

- Precise Residence Time Control – Narrow residence time distribution protects heat-sensitive materials

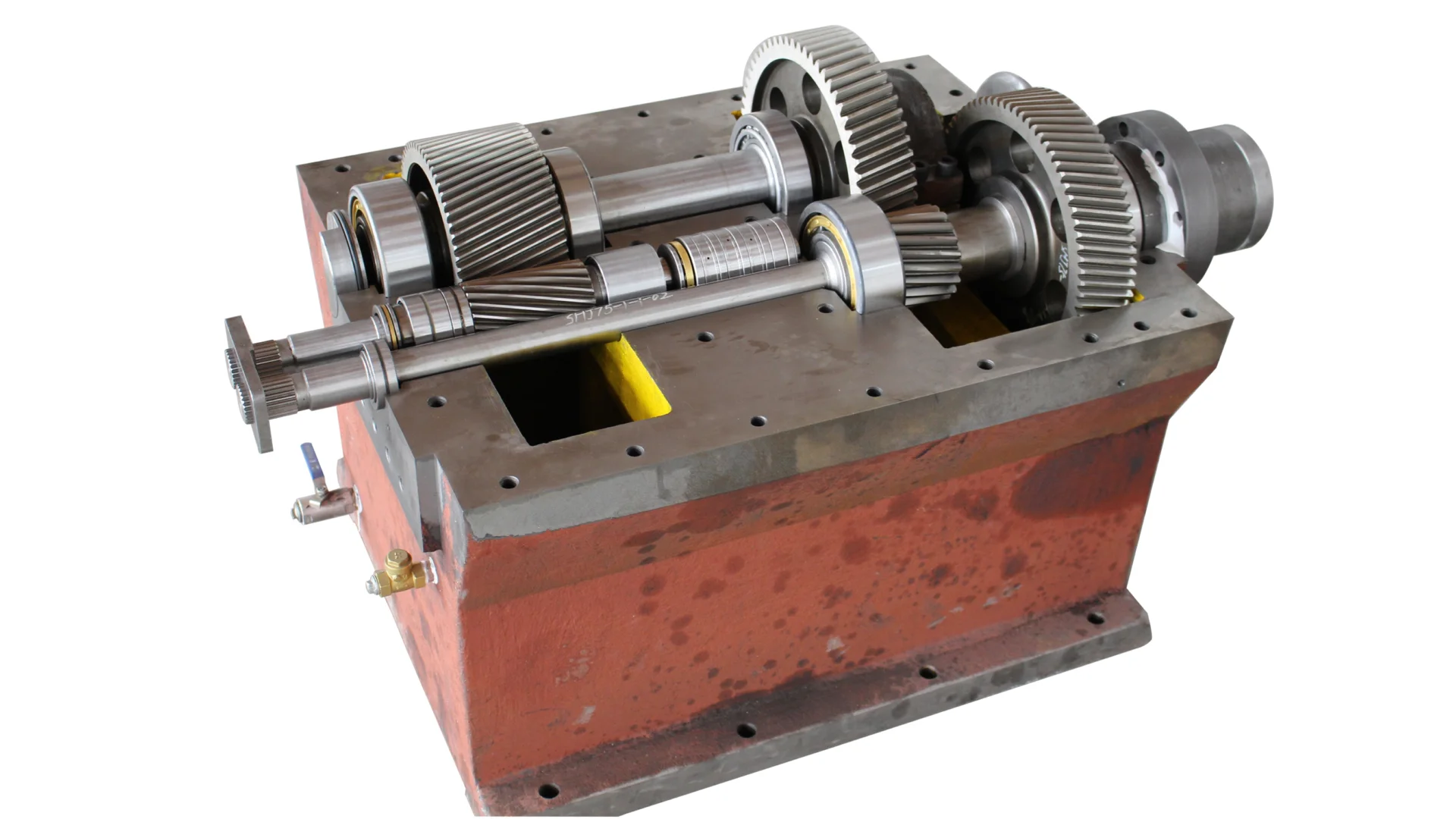

4. Robust Power Transmission System

Reliability begins with premium components. Energycle extruders feature:

- Heavy-duty gearbox – with precision-ground, case-hardened gear teeth for smooth torque distribution

- High-quality imported bearings – rated for continuous operation under demanding loads

- Integriertes Schmiersystem mit Temperaturüberwachung zur Verlängerung der Lebensdauer der Komponenten

- Überlastschutz um Ihre Investition bei unerwarteten Prozessbedingungen zu schützen

5. Premium Materialien & Konstruktion

Jede Komponente ist auf Langlebigkeit ausgelegt:

- Hartgeglühte, nitrierte Behälterabschnitte bestehen dem Verschleiß durch abrasives Füllmaterial standhaft

- Bimetallische Behälterauskleidungen (optional) für extreme Verschleißfestigkeit mit Glasfaser- oder mineralgefüllten Compounds

- Robuste soudée en acier Dotée de pads d'ajustement de précision pour garantir l'alignement correct

- Revêtements d'isolation en acier inoxydable pour le fût Maintiennent l'efficacité thermique et la sécurité de l'opérateur

6. Technologie de Changement d'Écran Avancée

Assurez une production continue avec nos systèmes de filtration de fusion innovants :

- Changeurs de tamis glissants hydrauliques – Changements de tamis rapides et sans interruption de production

- Changeurs de tamis à bande continue – Filtration automatique pour une sortie ultra-c净e dans les applications critiques

- Cesta-type screen changers – Economical solution for standard filtration requirements

Each system is designed to integrate seamlessly with downstream pelletizing, profiling, or sheet extrusion machinery.

High-precision gearbox internals engineered for dependable torque distribution and prolonged service life

Co-Rotating vs. Counter-Rotating: Understanding the Distinction

Although both configurations cater to extrusion requirements, co-rotating twin screw extruders provide distinct benefits:

| Značajka | Co-Rotating | Counter-Rotating |

|---|---|---|

| Self-cleaning | Excellent – screws effectively clean each other completely | Material accumulation in intermesh zone limited |

| Mixing Intensity | Excellent for both distributive and dispersive mixing | Ideal for delicate mixing |

| Modular Design Flexibility | Highly modular – simple screw reconfiguration | Limited design modularity |

| Prijave | Compounding, reactive extrusion, devolatilization processes | Profile extrusion, pipe manufacturing |

| Material versatility | Manages broad viscosity spectrum | Optimized for materials with consistent viscosity |

In polymer compounding, masterbatch manufacturing, and intricate formulations, co-rotating designs provide unparalleled performance.

Your Trusted Partner in Extrusion Technology

With over 20 years of specialized experience positions Energycle as your dependable manufacturing ally. We recognize that each application brings its own set of unique challenges—from attaining stringent color tolerances in masterbatch production to maximizing throughput in recycled resin compounding.

Our engineering team collaborates with you to:

- Choose the most suitable screw configurations for your materials

- Design processing zones that strike a balance between mixing quality and energy efficiency

- Scale processes from the laboratory to full-scale production

- Fournir un soutien technique continu et optimiser les processus

Que vous traitiez des plastiques techniques, créiez des masterbatchs de couleur, compoziez des polymères renforcés par du verre ou développiez des matériaux innovants à base de bio, Energycle korotirajući ekstruderi s dva puža assure la précision et la fiabilité que votre exploitation nécessite.

Prêt à élèvez vos opérations de compounding ?

Discutons de la manière dont la technologie Energycle peut résoudre vos défis de traitement spécifiques. Nos ingénieurs en application sont prêts à examiner vos besoins en matière, vos objectifs de production et vos spécifications techniques.

Contactez l'équipe Energycle aujourd'hui pour explorer les configurations d'extrudeuses personnalisées selon vos besoins. Nous nous engageons à vous aider à atteindre :

- Une qualité de produit supérieure avec une meilleure cohérence

- Une efficacité de production accrue et une réduction des déchets

- Un coût total de possession inférieur grâce à un design durable

- Plus rapide mise sur le marché pour les nouvelles formulations

Transformez vos capacités de traitement de polymères avec Energycle – où l'excellence technique rencontre la fiabilité de fabrication.