Sink-float separation tanks are essential components in plastic recycling. They play a key role in cleaning and sorting plastic materials that are denser than water, such as PET, PVC, and PS. These tanks combine washing, separation, and sediment removal in a single system, streamlining the recycling process and improving material purity. Here’s a detailed look at their functions, features, operation, and benefits.

Functions of Sink-Float Separation Tanks

1. Rinsing

Sink-float tanks remove surface dirt and impurities from plastic materials submerged in water. This ensures a cleaner material for downstream processing.

2. Label Separation

Light contaminants such as labels and films are separated using water flow and density differences. These materials float to the surface while heavier plastics sink.

3. Mud and Sand Removal

Heavier contaminants like sand and mud are eliminated through sedimentation and the action of bottom screws.

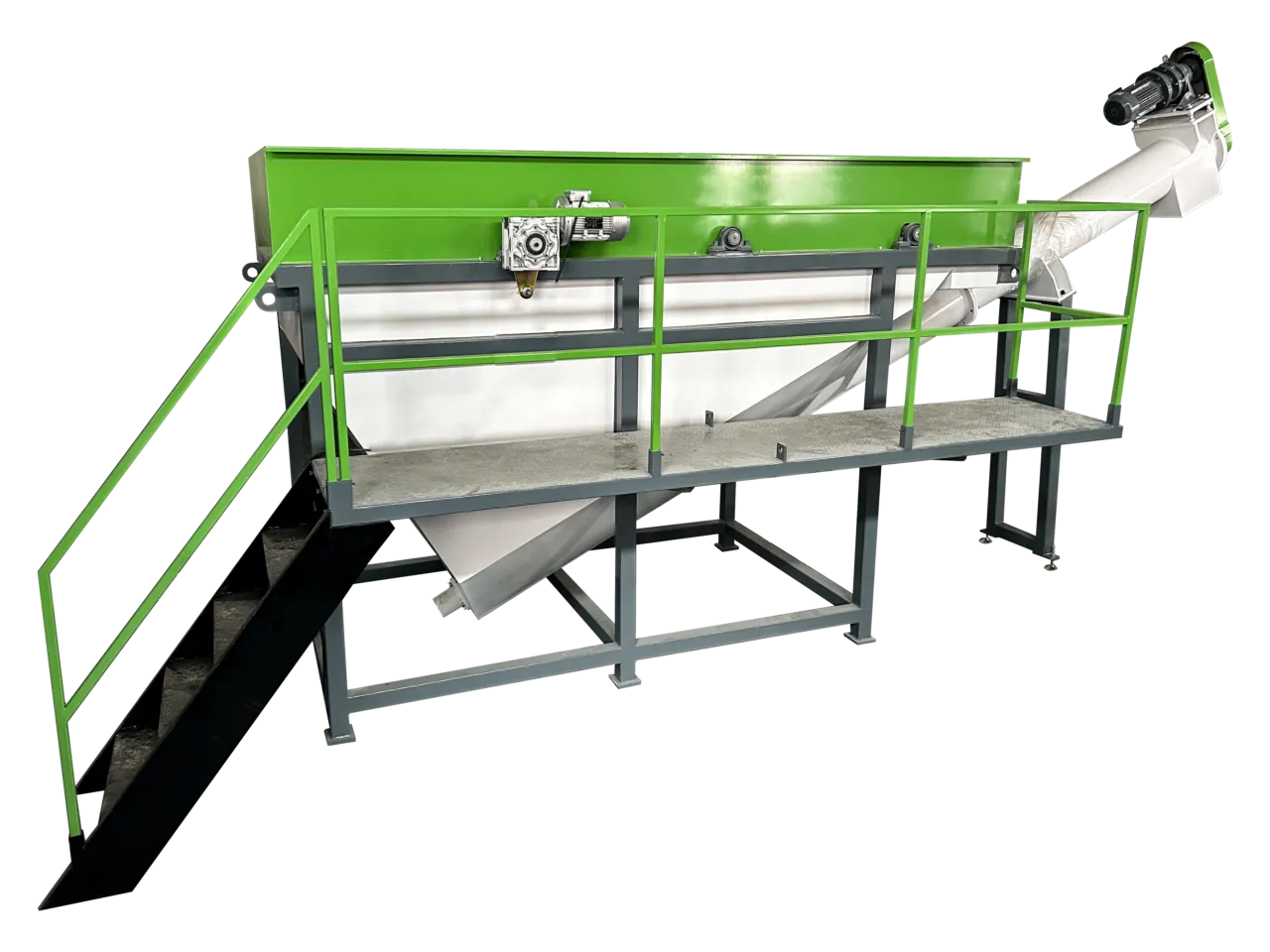

Key Features

- Tailored for Heavier Plastics: Designed specifically for plastics with a density greater than water, including PET, PVC, and PS.

- Bottom Screw Friction Cleaning: Equipped with a screw at the base of the tank, it effectively cleans plastics through friction and removes sediment simultaneously.

How It Works

- Feeding: Shredded plastic enters the tank through an inlet.

- Water Rinsing: Water is added to rinse the plastics and dislodge loose dirt.

- Density-Based Separation: Lighter contaminants like labels float, while heavier plastics settle at the bottom.

- Bottom Screw Cleaning: A rotating screw at the tank’s base applies friction to clean settled plastics while directing heavy impurities, like sand, to the discharge outlet.

- Discharge: Cleaned plastics exit through a designated outlet, ready for the next recycling stage.

Advantages

- Enhanced Recycling Quality: By removing impurities such as labels, dirt, and sediment, sink-float tanks increase the purity of recycled plastics, ensuring better end products.

- Efficient Multi-Functionality: The tank simultaneously washes, separates, and removes sediments, saving time and improving operational efficiency.

- Targeted Design: Engineered specifically for denser plastics, the tank delivers effective separation with high reliability.

Conclusion

Sink-float separation tanks are indispensable for recycling operations that handle denser plastics. Their ability to rinse, separate, and clean in one unit not only improves material quality but also enhances overall process efficiency. By integrating targeted designs and potential upgrades like flotation systems and water recycling, these tanks can further optimize plastic recycling outcomes. Businesses seeking higher recycling standards and sustainability will find sink-float tanks to be a valuable investment.