Recycling News

Understanding the Different Types of Plastic Pelletizer: Which One Suits Your Recycling Needs?

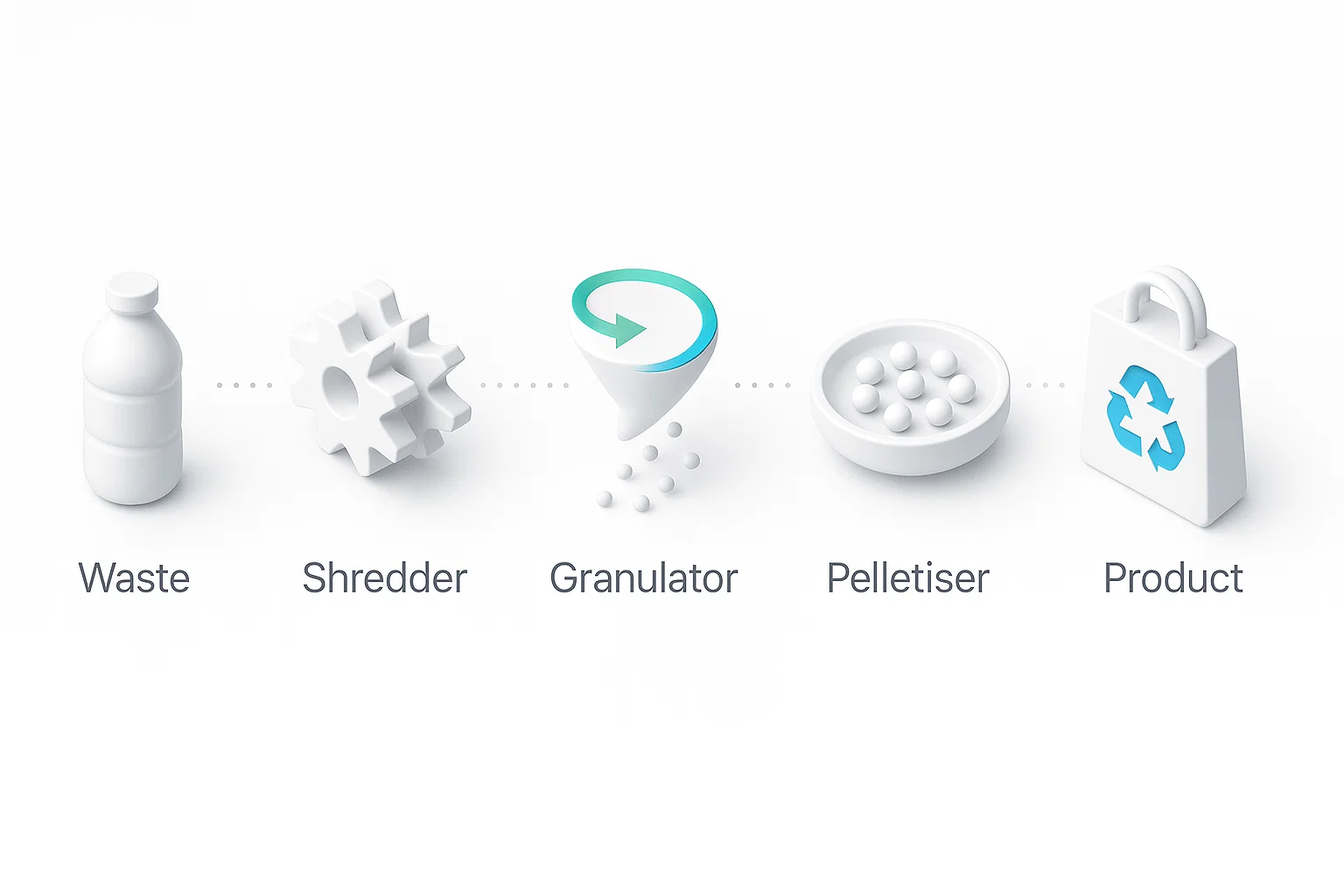

The global shift towards a circular economy has placed plastic recycling at the forefront of sustainable industrial practices. For businesses involved in transforming plastic waste into reusable raw materials, the Plastic Pelletizer is an indispensable piece of machinery. These robust systems convert cleaned and often shredded or molten plastic into uniform pellets, which are then ready to be reintroduced into manufacturing processes.

However, with various types of Plastic Pelletizers available, each designed for specific applications and plastic types, selecting the right one is crucial for optimising your recycling operations, ensuring pellet quality, and maximising your return on investment. This comprehensive guide from Energycle will walk you through the different Plastic Pelletizer technologies, helping you determine which best aligns with your unique recycling requirements.

At Energycle, we understand the critical role that efficient and reliable machinery plays in your success. Explore our range of cutting-edge Plastic Pelletizers designed to meet the diverse needs of the modern recycling industry.

Why Pelletizing? The Importance of Uniformity and Quality

Before diving into the types of pelletizers, it's worth reiterating why pelletizing is a critical step in plastic recycling:

- Ease of Handling and Storage: Uniform pellets are significantly easier to handle, transport, and store compared to irregularly shaped plastic flakes or powders.

- Improved Material Consistency: Pelletizing homogenises the plastic, leading to a more consistent melt flow index (MFI) and better performance in subsequent manufacturing processes.

- Increased Bulk Density: Pellets have a higher bulk density than flakes, which can reduce transportation costs and improve feeding efficiency in extruders.

- Reduced Dust and Fines: This leads to cleaner operations and minimises material loss.

- Enhanced Market Value: High-quality, uniform pellets command a better price in the recycled plastics market.

Key Types of Plastic Pelletizer Systems

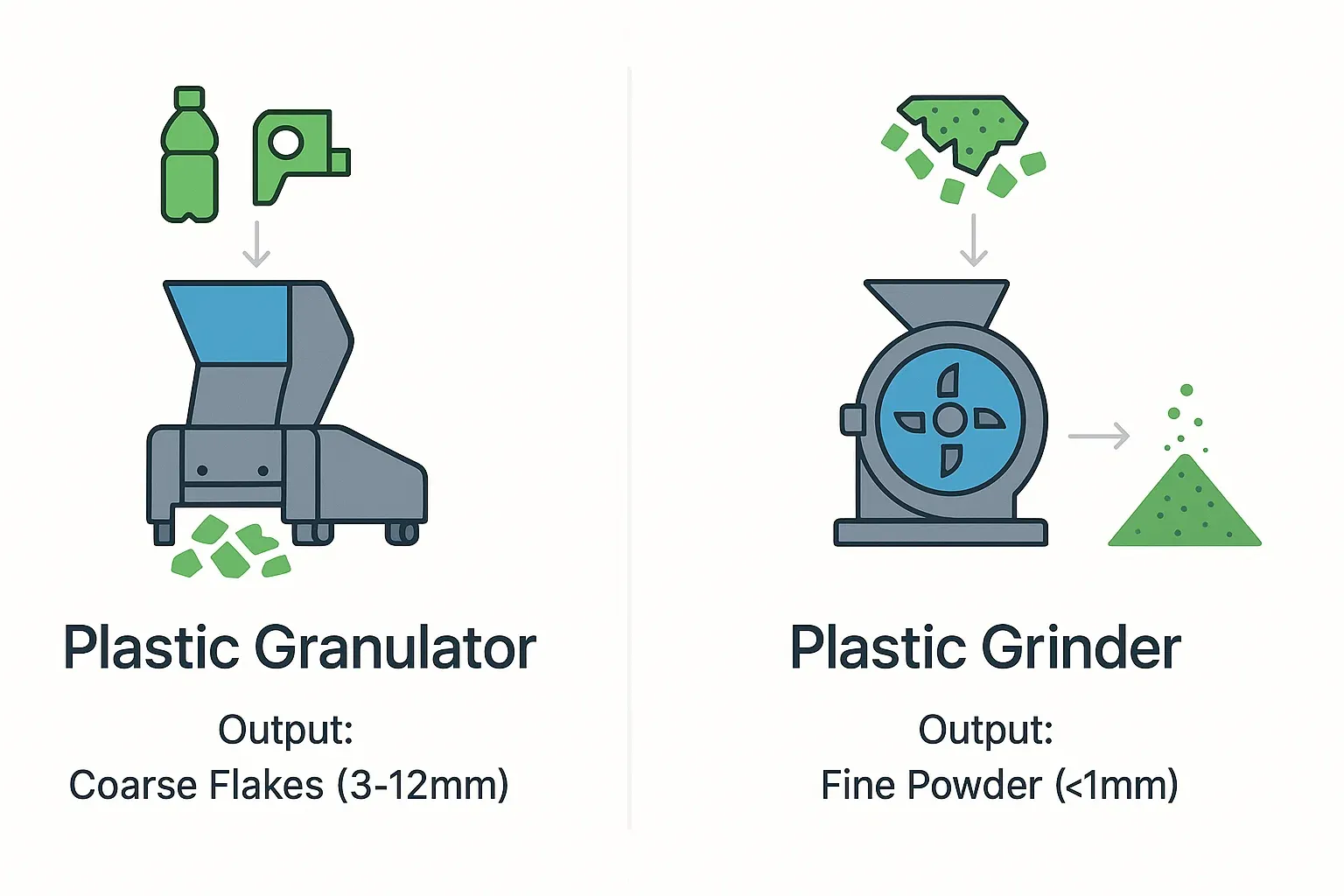

Plastic Pelletizers can be broadly categorised based on their cutting mechanism and where the cutting takes place relative to the die. The two primary categories are Strand Pelletizers and Die-Face Pelletizers (which include underwater and water-ring systems).

1. Strand Pelletizers

Strand pelletizing is a well-established and versatile method suitable for a wide range of polymers, particularly those that are sensitive to melt fracture or have lower melt strength.

Workflow:

- Extrusion: Molten plastic is extruded through a die head, forming continuous strands.

- Cooling: These strands are then typically cooled by passing them through a water bath or by air cooling.

- Drying: After cooling, any residual water is removed from the strands using an air knife or a dewatering unit.

- Cutting: The cooled and dried strands are fed into a pelletizer unit, where a rotor with multiple knives cuts them into cylindrical or cubical pellets of a defined length.

Advantages of Strand Pelletizers:

- Versatility: Suitable for a wide variety of thermoplastics, including filled materials and engineering plastics.

- Cost-Effective: Generally, strand pelletizing lines can have a lower initial investment cost compared to die-face systems for certain capacities.

- Good Pellet Quality: Can produce highly uniform pellets when properly operated.

- Easier Maintenance: The cutting chamber and knives are typically more accessible for cleaning and maintenance.

Considerations for Strand Pelletizers:

- Labour Intensive: Can require more operator attention, particularly during start-up and if strands break.

- Space Requirements: The cooling trough and drying sections can make the footprint of the line quite long.

- Fines and Dust: Potential for higher levels of fines or dust if strands are not adequately cooled or if the cutter is not well-maintained.

Ideal Applications:

- Compounding operations.

- Recycling of less abrasive materials.

- Processing heat-sensitive polymers.

- Smaller to medium-throughput operations where versatility is key.

2. Die-Face Pelletizers

In die-face pelletizing systems, the plastic is cut directly at the face of the extruder die. This method is often preferred for higher throughputs and for processing materials that are difficult to handle as strands. There are two main sub-types: Water-Ring Pelletizers and Underwater Pelletizers.

a) Water-Ring Pelletizers (WRP)

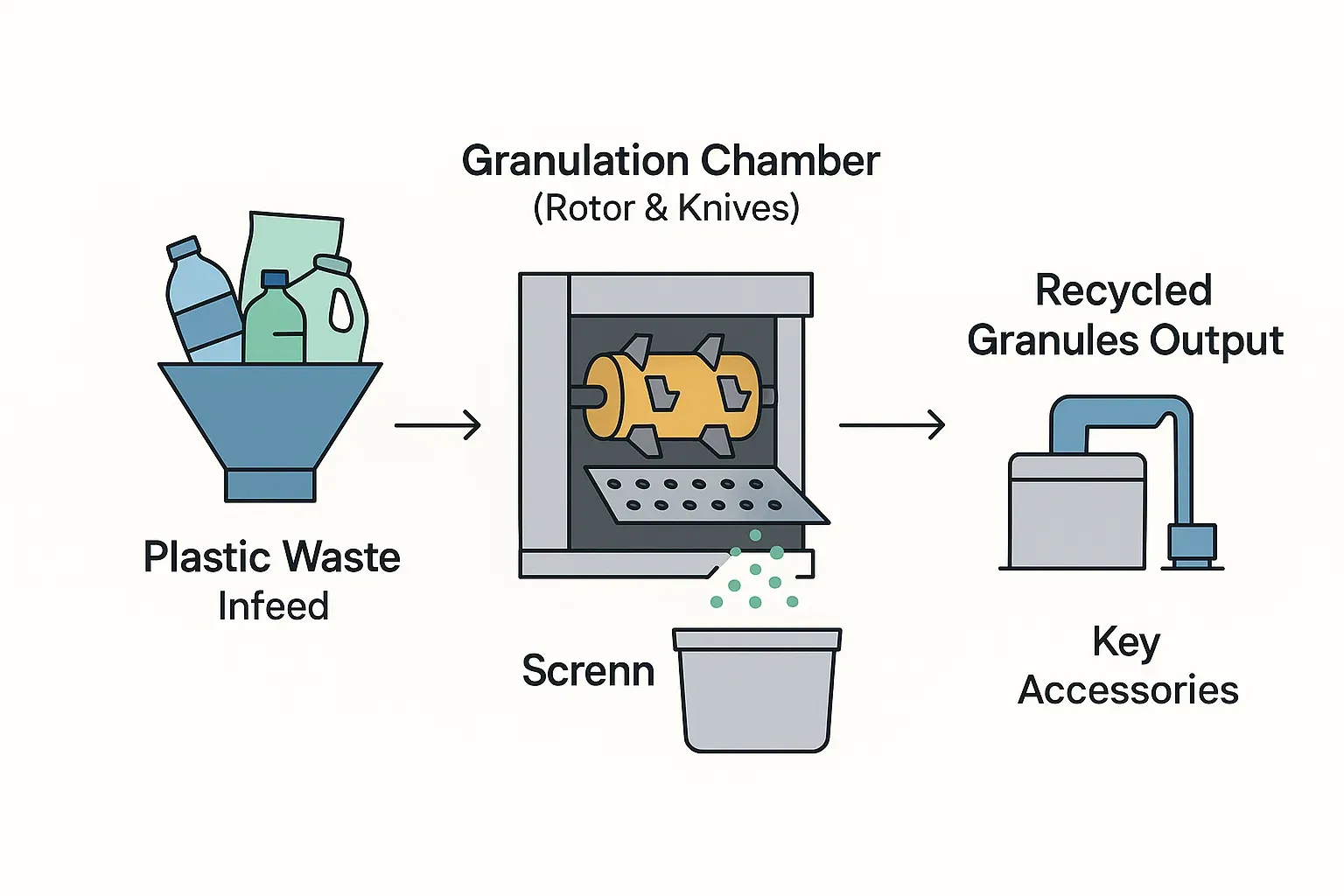

Workflow:

- Extrusion: Molten polymer is extruded through the die holes.

- Cutting: Rotating knives sweep across the die face, cutting the molten strands into pellets.

- Cooling & Transport: Immediately after cutting, the pellets are thrown outwards by centrifugal force into a circulating water ring that cools and transports them.

- Drying: The pellets and water are then separated in a centrifugal dryer.

Advantages of Water-Ring Pelletizers:

- Compact Design: Generally more compact than strand pelletizing lines.

- Good for Polyolefins: Particularly well-suited for materials like polyethylene (PE) and polypropylene (PP).

- Automated Operation: Typically requires less operator intervention than strand pelletizers.

- Uniform Pellet Shape: Produces spherical or oval pellets which can be advantageous for some applications.

Considerations for Water-Ring Pelletizers:

- Material Limitations: May not be ideal for very soft, sticky (tacky), or highly abrasive materials.

- Thermal Stress: The rapid cooling can sometimes induce thermal stress in certain polymers.

Ideal Applications:

- High-throughput recycling of PE and PP.

- Applications where a more spherical pellet is desired.

- Operations where space is a constraint.

b) Underwater Pelletizers (UWP)

Workflow:

- Extrusion: Molten polymer is extruded through the die plate directly into a tempered water chamber.

- Cutting: Rotating knives cut the polymer strands into pellets as they emerge from the die, all under water.

- Cooling & Transport: The water cools the pellets and transports them as a slurry to a centrifugal dryer.

- Drying: The pellets are separated from the water and dried.

Advantages of Underwater Pelletizers:

- Excellent Pellet Quality: Produces highly uniform, typically spherical pellets with minimal fines or agglomerates.

- Handles Difficult Materials: Ideal for a very wide range of thermoplastics, including those that are very soft, tacky, brittle, or temperature-sensitive, as well as highly filled compounds.

- High Throughput: Capable of very high production rates.

- Enclosed System: Minimises operator exposure to fumes and dust.

- Consistent Cooling: The direct contact with water ensures rapid and uniform cooling.

Considerations for Underwater Pelletizers:

- Higher Initial Investment: Typically the most expensive type of Plastic Pelletizer.

- More Complex Operation: Requires precise control of water temperature and flow.

- Maintenance: Can be more complex to maintain, especially the die plate and cutting chamber.

Ideal Applications:

- Large-scale recycling operations.

- Processing a wide variety of polymers, including challenging ones like PET, PA, TPU, and bioplastics.

- Applications demanding the highest pellet quality and uniformity.

- Production of micro-pellets.

Choosing the Right Plastic Pelletizer for Your Needs

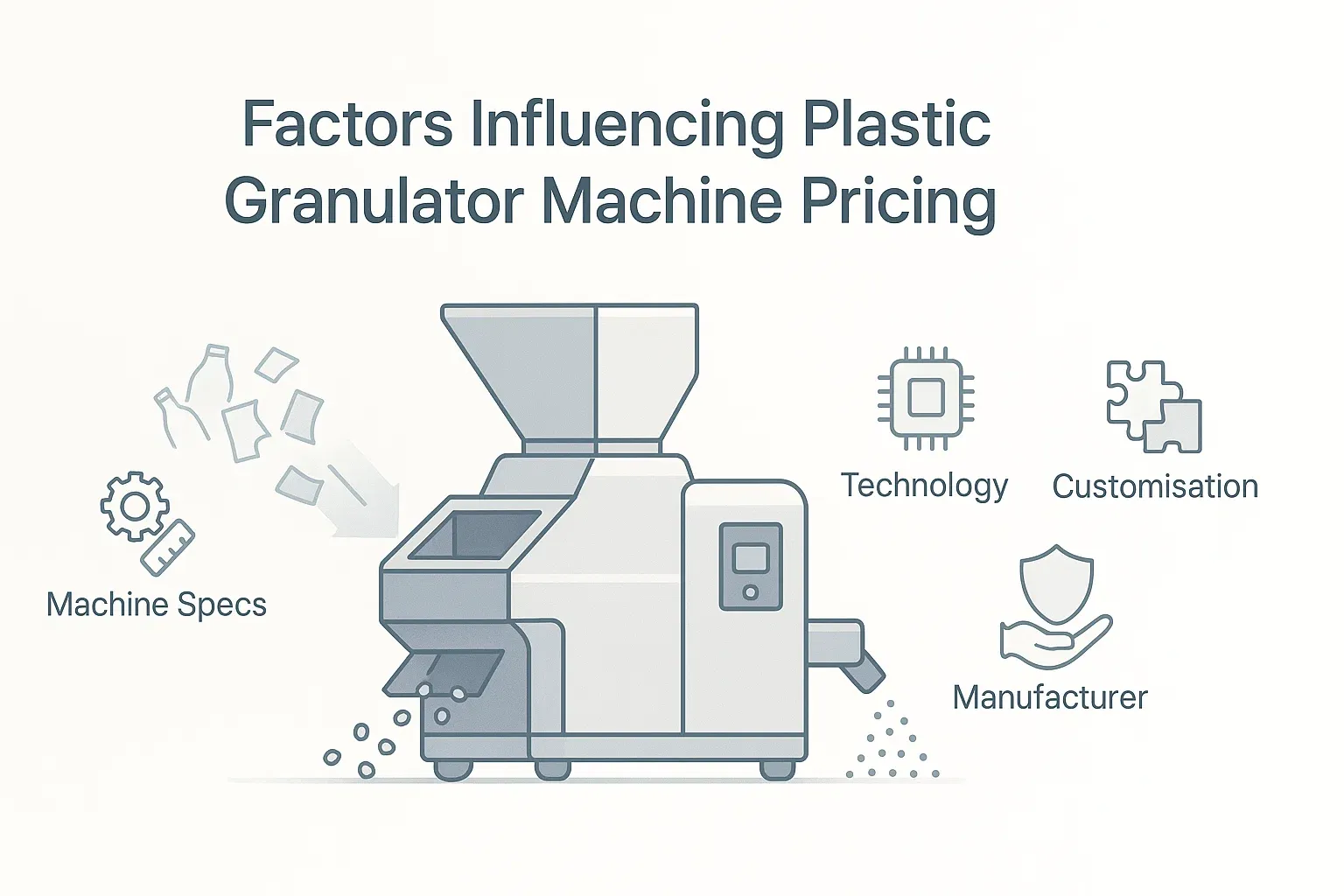

Selecting the optimal Plastic Pelletizer involves a careful assessment of several factors:

- Type of Plastic Being Processed:

- Polyolefins (PE, PP): All systems can handle these, but WRP and UWP are common for high throughputs. Strand pelletizers offer versatility for various grades.

- Engineering Plastics (PET, PA, PC, ABS): UWPs excel due to their ability to handle varying melt strengths and provide consistent pellet quality. Strand pelletizers are also viable, especially for smaller batches or specific compounds.

- Heat-Sensitive Plastics (PVC, some bioplastics): UWPs offer gentle and controlled cooling. Strand pelletizers with appropriate cooling can also be used.

- Highly Filled or Abrasive Materials: UWPs are often preferred due to their robust design, though specially designed strand pelletizers can also be suitable.

- Required Throughput:

- Low to Medium: Strand pelletizers can be very cost-effective.

- Medium to High: Water-ring pelletizers offer a good balance of performance and cost.

- Very High: Underwater pelletizers are typically the go-to solution.

- Desired Pellet Quality and Shape:

- Cylindrical/Cubical: Strand pelletizers.

- Spherical/Oval: Water-ring and underwater pelletizers. UWPs generally produce the most uniform spherical pellets.

- Available Budget:

- Strand pelletizers often have the lowest initial cost.

- Water-ring pelletizers are mid-range.

- Underwater pelletizers represent the highest initial investment but can offer lower long-term operational costs at high throughputs due to automation and efficiency.

- Operational Considerations:

- Space Availability: WRPs and UWPs are generally more compact than strand lines.

- Labour Availability and Skill Level: Strand lines may require more manual intervention. Die-face systems are typically more automated.

- Maintenance Requirements: Consider the ease of access for cleaning, knife changes, and die plate maintenance.

| Feature | Strand Pelletizer | Water-Ring Pelletizer (WRP) | Underwater Pelletizer (UWP) |

| Cutting Action | Cooled strands cut by rotating knives | Molten pellets cut at die face, cooled by water ring | Molten pellets cut at die face, under water |

| Pellet Shape | Cylindrical / Cubical | Spherical / Lenticular | Spherical / Oval |

| Typical Materials | Wide range, inc. filled, sensitive | Polyolefins (PE, PP), some others | Very wide range, inc. tacky, brittle, soft, PET, PA |

| Throughput | Low to Medium | Medium to High | High to Very High |

| Footprint | Can be long | Compact | Relatively Compact |

| Automation | Lower | Medium to High | High |

| Initial Cost | Lower | Medium | Higher |

| Pellet Uniformity | Good to Very Good | Good to Very Good | Excellent |

| Key Advantage | Versatility, lower initial cost | Good for polyolefins, compact | Highest quality, handles difficult materials |

| Consideration | Strand breakage, labour intensive | Material limitations (e.g. tacky) | Higher cost, complex operation |

The Energycle Advantage

At Energycle, we don't just sell machinery; we provide solutions. Our team of experts possesses deep technical knowledge of plastic recycling processes and Plastic Pelletizer technology. We work closely with our clients, including industrial recycling equipment buyers, engineers, and professionals across related sectors, to understand their specific challenges and objectives.

Whether you are processing post-consumer film, rigid regrind, or industrial scrap, we can help you select and implement the Plastic Pelletizer system that delivers optimal performance, reliability, and value. Our Plastic Pelletizers are engineered for durability, efficiency, and ease of operation, ensuring you achieve the highest quality recycled pellets.

Conclusion

Choosing the right Plastic Pelletizer is a critical decision that directly impacts the efficiency and profitability of your plastic recycling operations. By understanding the distinct advantages and ideal applications of strand, water-ring, and underwater pelletizers, you can make an informed choice that aligns with your material types, throughput requirements, quality specifications, and budget.

The journey to optimised plastic recycling begins with the right equipment. Contact Energycle today to discuss your Plastic Pelletizer needs and discover how our innovative solutions can empower your business to thrive in the circular economy. Our commitment is to provide you with machinery that not only meets but exceeds your expectations, contributing to a more sustainable future, one pellet at a time.

Decoding Plastic Code 3: Your Guide to Understanding PVC and Its Responsible Management

Ever glanced at the bottom of a plastic product, seen the chasing arrows успіх with a number "3" inside, and wondered what it means? That little symbol is your key to identifying Polyvinyl Chloride, commonly known as PVC. Understanding this versatile yet complex plastic is crucial for making informed decisions about its use, recycling, and disposal. Let's dive into what plastic code 3 signifies and how we can handle PVC responsibly to protect our health and the environment.

Getting to Know PVC (Recycling Code 3)

Polyvinyl Chloride, or PVC, stands out in the world of plastics. It's a highly adaptable material that comes in two primary forms:

- Rigid PVC: Strong, durable, and weather-resistant, rigid PVC is a mainstay in the construction industry. You'll find it in window frames, pipes, gutters, and siding. It's also used for everyday items like credit cards and gift cards.

- Flexible PVC: By adding plasticizers, PVC can be transformed into a soft, pliable material. This form is used in a wide array of products, including electrical cable insulation, medical tubing and bags, inflatable pool toys, shower curtains, and some types of clothing and upholstery.

The number "3" inside the recycling symbol is the resin identification code specifically for PVC. This system was developed to help recyclers differentiate various types of plastics, which is a critical first step in the recycling process.

The Hurdles: Why PVC Recycling Isn't Always Straightforward

While the recycling symbol might suggest a simple path to a new life for PVC products, the reality is more complex. PVC recycling faces several significant challenges:

- High Chlorine Content: PVC contains a high percentage of chlorine (about 57% by weight). When PVC is melted during recycling or improperly incinerated, this chlorine can lead to the formation of harmful substances like hydrogen chloride (a corrosive acid) and dioxins.

- Variety of Additives: To achieve its diverse properties, PVC is often mixed with a range of additives. These can include:

- Plasticizers (like phthalates): Used to make PVC flexible.

- Stabilizers (historically including lead or cadmium, now often tin-based or organic compounds): To prevent degradation from heat and light.

- Fillers and pigments. These additives can complicate the recycling process, as they can affect the quality of the recycled material and may release harmful chemicals if not handled correctly.

- Contamination: PVC waste streams can be easily contaminated with other plastics or materials, making it difficult to achieve the purity needed for high-quality recycling.

- Low Acceptance in Curbside Programs: Due to these complexities, many municipal curbside recycling programs do not accept PVC. This means that much of it, unfortunately, ends up in landfills if consumers aren't aware of alternative disposal routes.

Environmental and Health Considerations: The "Why" Behind Responsible PVC Management

The challenges in recycling PVC are closely linked to its potential environmental and health impacts throughout its lifecycle – from production to disposal:

- Toxic Releases During Production and Disposal: The manufacturing of PVC involves vinyl chloride monomer (VCM), a known human carcinogen. If PVC is incinerated, it can release highly toxic compounds like dioxins and furans. Dioxins are persistent organic pollutants that can accumulate in the food chain and have been linked to cancer, reproductive and developmental problems, immune system damage, and interference with hormones.

- Harmful Additives:

- Phthalates: Certain phthalates, commonly used in flexible PVC, are endocrine disruptors, meaning they can interfere with the body's hormonal systems. Exposure has been linked to developmental issues, reproductive problems, and an increased risk of allergies and asthma.

- Heavy Metals: Although their use has decreased, older PVC products might contain heavy metals like lead and cadmium as stabilizers, which are toxic and can leach into the environment.

- Microplastic Pollution: Like all plastics, PVC can break down into microplastics over time, contributing to pollution in our soils, waterways, and oceans, potentially entering the food chain.

Understanding these risks underscores why proper handling and disposal of PVC are so critical.

Navigating Proper Disposal and Recycling of PVC

So, what should you do with PVC products once you no longer need them? Here’s how to approach it responsibly:

- Check Your Local Recycling Guidelines First: This is always the most crucial step. Recycling capabilities vary significantly from one municipality to another.

- How to Check: Visit your city or county's official waste management website. Look for a detailed list of accepted plastics or a recycling guide. Some areas may have a dedicated phone hotline (like Earth911's 1-800-CLEANUP in the U.S.) or online search tools (e.g., Earth911.com, RecycleNation.com) that allow you to search by material and zip code.

- Seek Out Specialized PVC Recycling Facilities: If your local curbside program doesn't accept PVC (which is common), don't lose hope! Specialized recycling facilities are sometimes equipped to handle it.

- What Makes Them Specialized? These facilities often have advanced sorting technologies to separate PVC from other plastics and contaminants. They may use mechanical recycling processes tailored for PVC, which involve grinding, melting, and reforming the plastic, or even chemical recycling methods. They are also better equipped to manage the potentially harmful substances associated with PVC.

- Explore Take-Back Programs and Donations:

- Some manufacturers or retailers, particularly in the construction industry (e.g., for pipes or window frames), may have take-back programs for old PVC products.

- If PVC items like pipes or vinyl siding are still in good condition, consider donating them to organizations that accept used building materials, such as Habitat for Humanity ReStores.

- Alternative Disposal – When Recycling Isn't an Option: If recycling options are unavailable, your last resort is disposal.

- Avoid Burning: Never burn PVC products in a backyard fire pit or uncontrolled setting due to the release of toxic fumes.

- Responsible Landfilling: If landfilling is the only option, ensure it's done according to your local waste management regulations. While not ideal due to potential leaching of additives over time, it's preferable to improper dumping. The primary goal should always be to divert PVC from landfills whenever possible.

Innovations and the Future of PVC Recycling

Despite the challenges, efforts are underway to improve PVC recycling and make it more sustainable:

- Mechanical Recycling Advancements: Improvements in sorting, cleaning, and processing technologies are helping to produce higher-quality recycled PVC from certain waste streams.

- Chemical Recycling Technologies: These emerging technologies aim to break PVC down into its chemical components, which can then be used to create new virgin-quality PVC or other valuable chemicals. Examples include:

- Pyrolysis: Heating plastics in the absence of oxygen.

- Gasification: Converting plastics into a synthesis gas.

- Solvent-based dissolution (like the VinyLoop® process, though its operational status can vary): This process dissolves PVC from mixed waste and then precipitates it out as a pure recycled material. While promising, many chemical recycling technologies are still in development, facing challenges in terms of scalability, cost-effectiveness, and ensuring a genuinely circular environmental benefit (rather than just converting plastic to fuel, which is not true recycling).

- Industry Initiatives: Programs like VinylPlus® in Europe are working towards increasing the collection and recycling of PVC waste and promoting the use of recycled PVC.

These innovations offer hope for a more circular economy for PVC, but they require continued investment, research, and supportive policies.

Your Role in a Sustainable Future

By recognizing recycling code 3 and understanding the specific considerations for PVC, you're already taking a positive step. Here’s how you can continue to make a difference:

- Be an Informed Consumer: Consider the materials products are made from and their end-of-life options before purchasing.

- Reduce and Reuse: Where possible, reduce your reliance on single-use plastic items. Choose durable, reusable alternatives.

- Dispose Responsibly: Always follow local guidelines for recycling and waste disposal. Advocate for better recycling infrastructure in your community if options are limited.

- Stay Curious: Keep learning about plastic recycling and sustainable waste management practices.

Managing PVC responsibly is a shared effort. By arming ourselves with knowledge and taking conscious actions, we can contribute to a healthier planet and a more sustainable approach to waste.

Plastic. It's a material that has truly shaped our modern world. From the packaging that keeps our food fresh and safe to the intricate components powering our smartphones and life-saving medical devices, plastic is undeniably woven into the fabric of our daily lives. But this convenience often comes with an environmental cost, sometimes called "white pollution" – the widespread issue of plastic waste accumulating in our ecosystems. This Comprehensive Plastic Classification Guide is designed to help you navigate the complex world of plastics. We'll explore the different types, their common uses, their properties, and, crucially, their impact on our planet. By understanding these distinctions, we can all make more informed choices, improve our recycling habits, and contribute to a healthier environment.

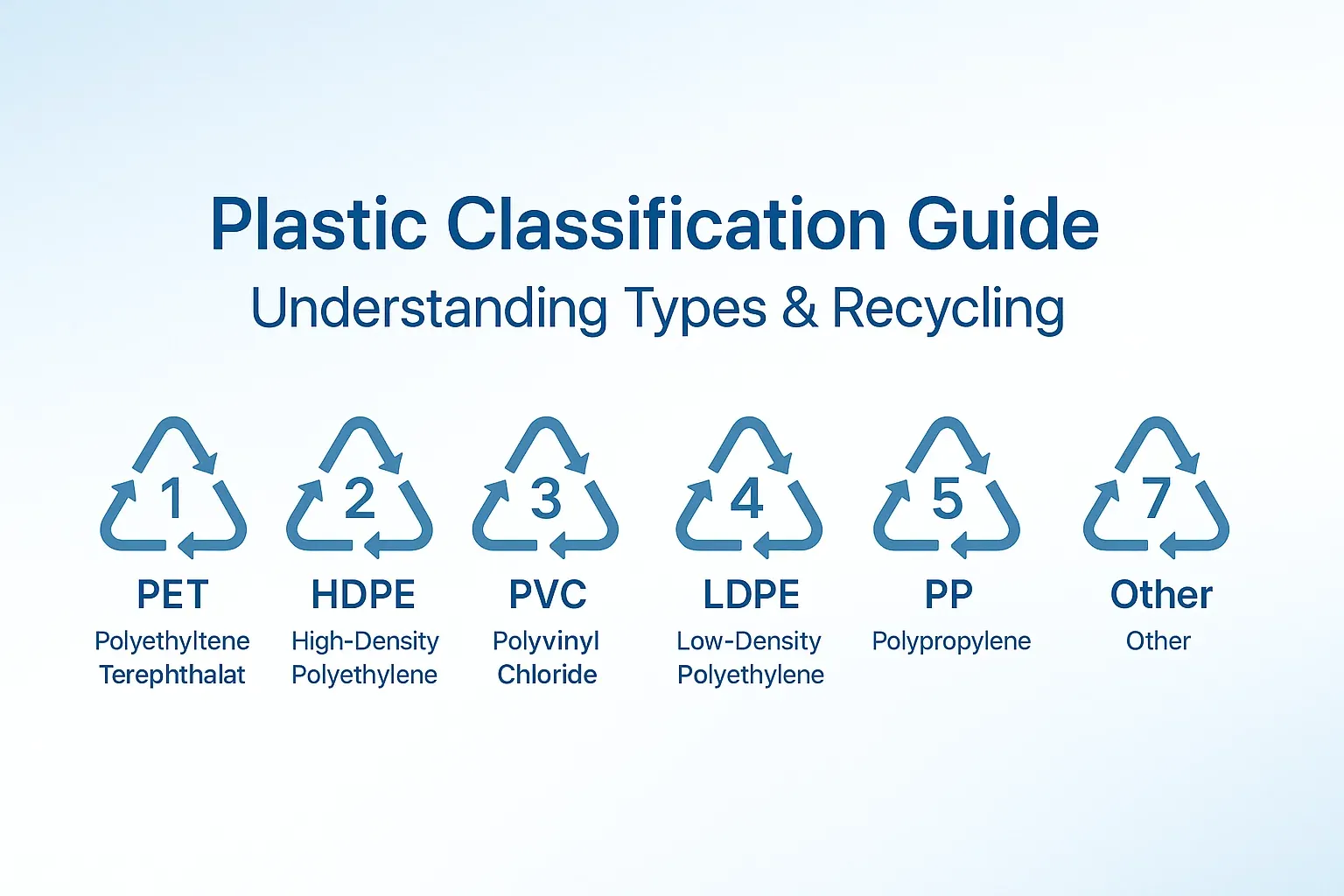

Why Understanding Plastic Types Matters

You've probably seen those little numbers in triangles on the bottom of plastic containers. Ever wondered what they mean? These are Resin Identification Codes (RICs), and they tell us about the type of plastic resin used to make the product. Knowing these codes isn't just for industry experts; it's crucial for consumers, manufacturers, and environmental advocates. This knowledge helps us:

- Recycle Effectively: Different plastics have different chemical compositions and cannot always be recycled together. Sorting plastics correctly prevents contamination in the recycling stream, leading to higher quality recycled materials.

- Make Safer Choices: Some plastics are better suited for food and drink storage than others. Understanding potential health risks associated with certain plastics can guide your purchasing decisions.

- Reduce Environmental Impact: By choosing plastics that are more readily recyclable or opting for alternatives, we can lessen the burden of plastic waste on our planet.

- Support a Circular Economy: Proper classification and recycling are key to closing the loop on plastic use, turning waste into valuable resources.

Your In-Depth Guide to Common Plastic Classifications

Plastics are a diverse family of synthetic or semi-synthetic materials that use polymers as a main ingredient. Their versatility means they can be molded, extruded, or pressed into solid objects of various shapes. Let's dive into the most common types you'll encounter, often identified by their Resin Identification Code (RIC).

#1 Polyethylene Terephthalate (PET or PETE)

Common Uses: This is one of the most common plastics you'll find. Think clear beverage bottles (water, soda), food containers (like peanut butter jars or salad dressing bottles), and even some textile fibers (polyester clothing).

Properties: PET is lightweight, strong, and typically transparent. It provides a good barrier to gas and moisture, which helps keep food and drinks fresh.

Recyclability & Safety: PET is widely recycled! It can be turned into new bottles, containers, carpet fibers, or fabric for clothing. While generally considered safe for single food and drink use, it's often recommended to avoid reusing PET containers for food/drink, especially if they show signs of wear or have been exposed to heat, due to the potential for chemical leaching and bacterial growth.

#2 High-Density Polyethylene (HDPE)

Common Uses: HDPE is another very common and versatile plastic. You'll find it in milk jugs, detergent and shampoo bottles, grocery bags, cereal box liners, and even some plastic lumber, pipes, and toys.

Properties: It's known for its excellent strength-to-density ratio, making it sturdy and resistant to moisture and chemicals. It can be translucent or opaque.

Recyclability & Safety: HDPE is widely recycled and considered one of the safer plastics for food and drink. Recycled HDPE is used to make new bottles, pipes, plastic lumber, and more.

#3 Polyvinyl Chloride (PVC or V)

Common Uses: PVC is a durable and versatile plastic used in things like plumbing pipes, window frames, vinyl flooring, electrical cable insulation, some clear food packaging (like cling film, though less common now), and inflatable products.

Properties: It can be rigid or flexible, depending on the additives used. It's known for its durability and resistance to chemicals and weathering.

Recyclability & Safety: PVC is rarely recycled through curbside programs. Its production and disposal can release harmful chemicals, including dioxins and phthalates (plasticizers). Phthalates, in particular, have raised health concerns, and it's generally advised to avoid using PVC for food storage or for children's toys, unless specified as phthalate-free.

#4 Low-Density Polyethylene (LDPE)

Common Uses: LDPE is the flexible plastic often used for plastic shopping bags, bread bags, shrink wrap, squeezable bottles (like for honey or ketchup), and some food container lids.

Properties: It's soft, flexible, lightweight, and provides a good moisture barrier.

Recyclability & Safety: LDPE is not always accepted in curbside recycling programs, but many grocery stores offer collection points for clean and dry plastic bags and films. It's considered a relatively safe plastic for food contact. When recycling, ensure items are clean and dry, and check local guidelines or store drop-off programs.

#5 Polypropylene (PP)

Common Uses: PP is a sturdy plastic with good heat resistance. You'll find it in yogurt containers, margarine tubs, medicine bottles, bottle caps, straws, and some automotive parts and reusable food containers.

Properties: It's strong, flexible, and has a high melting point, making it suitable for items that need to withstand higher temperatures (like microwavable containers, though always check labels).

Recyclability & Safety: PP is increasingly accepted in curbside recycling programs. It's considered a safe plastic for food contact. Always check with your local recycling provider to see if they accept #5 plastics.

#6 Polystyrene (PS)

Common Uses: Polystyrene comes in two main forms: solid (used for disposable cutlery, CD cases, smoke detector housings) and foamed (commonly known by the trademark Styrofoam™), used for disposable coffee cups, food take-out containers, and packaging peanuts.

Properties: It's lightweight and provides good insulation, but it's also brittle.

Recyclability & Safety: PS is notoriously difficult to recycle and is not widely accepted in curbside programs. Its bulky, lightweight nature makes it expensive to transport and process. There are also concerns about styrene, a potential human carcinogen, leaching into food, especially when heated. Many communities are banning or restricting its use.

#7 Other (Miscellaneous Plastics)

Common Uses: This category is a catch-all for plastics not defined by the other six codes. It includes materials like Polycarbonate (PC), Acrylonitrile Butadiene Styrene (ABS), Polylactic Acid (PLA - a bioplastic), nylon, and acrylic. You might find these in baby bottles (though many are now BPA-free PC), reusable water bottles, electronics casings, car parts, and some food containers.

Properties: Varies widely depending on the specific resin or combination of resins.

Recyclability & Safety: These plastics are generally not recycled through municipal programs due to their varied chemical compositions and lack of specialized recycling facilities. Some, like polycarbonate, have faced scrutiny for containing Bisphenol A (BPA), an endocrine disruptor. Many manufacturers have moved to BPA-free alternatives. Bioplastics like PLA are designed to be compostable in industrial facilities but can contaminate conventional plastic recycling streams if mixed in.

Navigating the World of Plastics: Key Takeaways

Understanding the different types of plastics is more than just an academic exercise; it's a practical skill for everyday life. By recognizing these classifications, we can:

- Decode Labels: Quickly identify the type of plastic an item is made from using the Resin Identification Code.

- Recycle Smarter: Know which plastics are accepted by your local recycling program, reducing contamination and improving recycling efficiency. Remember, the chasing arrows symbol with a number identifies the *type* of plastic, not a guarantee that it's recyclable everywhere. Always check local guidelines!

- Prioritize Safety: Make informed choices about plastics used for food and drink, opting for safer alternatives when possible.

- Reduce "White Pollution": By making conscious choices to reduce, reuse, and correctly recycle plastics, we can all play a part in tackling plastic waste.

This Plastic Classification Guide is your starting point. The world of plastics is constantly evolving, with new materials and recycling technologies emerging. Stay curious, keep learning, and together we can make a positive impact on our environment.

Have Questions or Need Recycling Solutions?

Understanding plastics is the first step. If you're looking for advanced recycling machinery or have questions about tackling specific plastic waste streams, we're here to help. To get the latest information on our solutions, prices, and lead times, send us a message using the form below.

Rigid plastics are foundational materials across a multitude of industries, prized for their exceptional durability, versatility, and manufacturing efficiency. They are integral to countless aspects of modern life, from everyday conveniences to sophisticated technological advancements. This exploration focuses on some of the most prevalent rigid plastics, including High-Density Polyethylene (HDPE), Polypropylene (PP), and Polyvinyl Chloride (PVC), detailing their distinct characteristics and diverse applications.

1. High-Density Polyethylene (HDPE) – The Tough & Reliable Choice

Core Properties & Advantages:

- High Strength-to-Density Ratio: Delivers exceptional strength while remaining lightweight, providing an optimal balance for load-bearing applications.

- Excellent Chemical Resistance: Exhibits outstanding resilience against a wide array of solvents, acids, and bases, making it suitable for chemically demanding environments.

- Superior Moisture Resistance: Absorbs negligible water, rendering it ideal for humid conditions or liquid packaging.

- Durable and Impact Resistant: Its robust nature allows it to withstand significant impacts without cracking or breaking easily.

Common Application Areas:

- Containers and Bottles: Essential for everyday items like milk jugs and detergent bottles, valued for their safety and reliability.

- Pipes and Fittings: Extensively used in plumbing and irrigation systems due to their proven durability.

- Plastic Lumber: Employed for outdoor furniture, decking, and playground equipment, offering both aesthetic appeal and weather resistance.

- Children's Toys: Frequently chosen for durable toys owing to its high strength and non-toxic properties.

2. Polypropylene (PP) – The Lightweight & Heat-Resistant All-Rounder

Core Properties & Advantages:

- High Melting Point: Suitable for applications involving elevated temperatures, such as microwaveable food containers.

- Excellent Fatigue Resistance: Capable of enduring repeated bending without failure, exemplified in bottle cap hinges.

- Broad Chemical Resistance: Effectively resists many common acids, bases, and organic solvents.

- Lightweight: Possesses a lower density than many other plastics, contributing to lighter end products.

Common Application Areas:

- Automotive Parts: Used for bumpers, battery cases, and interior components, effectively balancing lightweight design with durability.

- Packaging: Ideal for food containers, caps, and closures, ensuring product safety and hygiene.

- Textiles: Features in carpets, upholstery, and non-woven fabrics, showcasing its versatility.

- Medical Devices: Employed in syringes and laboratory equipment, favored for its sterilizability.

3. Polyvinyl Chloride (PVC) – The Versatile & Economical Material

Core Properties & Advantages:

- Versatile Mechanical Properties: Can be formulated to be either rigid or flexible, depending on the additives used.

- Good Chemical Resistance: Demonstrates resistance to acids, bases, and salts.

- Effective Electrical Insulator: Serves as an ideal insulating material for various electrical applications.

- Durable and Long-Lasting: Resists environmental degradation effectively, ensuring a long service life.

Common Application Areas:

- Construction Materials: Widely used for pipes, window frames, and siding due to its economy and practicality.

- Electrical Cable Insulation: Protects electrical wiring, enhancing electrical safety.

- Medical Devices: Utilized for blood bags, tubing, and containers, known for safety and reliability.

- Consumer Goods: Found in credit cards, toys, and various household items, available in diverse forms.

4. Polyethylene Terephthalate (PET/PETE) – The Clear & Strong Packaging Star

Core Properties & Advantages:

- High Tensile Strength: Offers a combination of strength and light weight, resulting in robust and durable products.

- Excellent Barrier Properties: Provides good resistance to gases and moisture, crucial for preserving freshness in packaging.

- Highly Recyclable: Stands as one of the most widely recycled plastics, significantly contributing to environmental protection efforts.

- Transparent and Glossy Finish: Offers an aesthetically pleasing appearance for packaging, enhancing product appeal.

Common Application Areas:

- Beverage Bottles: The predominant material for soft drink and water bottles.

- Food Packaging: Used for trays, containers, and clamshell packaging, ensuring safety and hygiene.

- Textiles: Processed into polyester fibers for clothing and upholstery.

- Electronics: Incorporated into components within electronic devices due to its insulating properties.

5. Polystyrene (PS) – The Lightweight & Insulating Molding Expert

Core Properties & Advantages:

- Rigid and Transparent: Typically clear and hard, offering good visual appeal for many products.

- Good Insulator: Provides excellent thermal and electrical insulation.

- Easy to Mold and Shape: Its moldability makes it suitable for creating intricate designs.

Common Application Areas:

- Packaging Materials: Includes foam packaging, disposable cutlery, and CD cases.

- Consumer Electronics: Forms housings for televisions, computers, and appliances.

- Medical Equipment: Used for disposable items like syringes and laboratory containers.

- Toys and Models: Chosen for detailed and lightweight items due to its ease of molding.

6. Acrylonitrile Butadiene Styrene (ABS) – The Tough & Impact-Resistant Engineering Plastic

Core Properties & Advantages:

- High Impact Resistance: Exceptionally tough and resistant to physical impacts and shocks.

- Good Dimensional Stability: Maintains its shape effectively under stress and temperature variations.

- Easily Molded and Machined: Facilitates the manufacturing of complex parts with precision.

- Glossy Finish: Can be produced with a high-gloss surface, suitable for aesthetically driven products.

Common Application Areas:

- Automotive Parts: Includes dashboard components, wheel covers, and interior trims.

- Consumer Electronics: Forms durable housings for computers, printers, and gaming consoles.

- Toys: LEGO bricks are a renowned example of ABS's application in durable toys.

- Household Appliances: Used in parts for vacuum cleaners, refrigerators, and washing machines.

7. Polycarbonate (PC) – The Exceptionally Strong High-Performance Material

Core Properties & Advantages:

- Exceptional Impact Resistance: Virtually unbreakable, offering superior protection even under extreme conditions.

- High Transparency: Provides a clear, glass-like appearance.

- Heat Resistant: Capable of withstanding high temperatures without deforming.

- Good Electrical Insulator: Suitable for a variety of electronic applications requiring insulation.

Common Application Areas:

- Safety Equipment: Used in helmets, bulletproof glass, and protective shields.

- Optical Discs: The material of choice for CDs, DVDs, and Blu-ray discs.

- Automotive and Aerospace Components: Valued for creating lightweight yet strong parts.

- Electronics: Features in smartphone screens, laptop casings, and other display devices.

Quick Comparison of Common Rigid Plastics

| Plastic Type | Density (g/cm³) | Tensile Strength (MPa) | Common Applications |

| HDPE (High-Density Polyethylene) | 0.93–0.97 | 20–37 | Bottles, pipes, plastic lumber |

| PP (Polypropylene) | 0.90–0.92 | 30–50 | Automotive parts, packaging, textiles |

| PVC (Polyvinyl Chloride) | 1.16–1.58 | 50–60 | Pipes, electrical insulation, medical devices |

| PET (Polyethylene Terephthalate) | 1.38–1.40 | 55–75 | Beverage bottles, textiles, electronics |

| PS (Polystyrene) | 1.04–1.06 | 30–50 | Packaging, electronics housings, toys |

| ABS (Acrylonitrile Butadiene Styrene) | 1.04–1.06 | 40–50 | Toys, electronics, automotive parts |

| PC (Polycarbonate) | 1.20–1.22 | 60–70 | Safety equipment, optical discs, electronics |

Note: The values provided are approximate and can vary based on specific formulations and manufacturing processes.

Environmental Considerations: Rigid Plastics & a Sustainable Future

While the advantages of rigid plastics are numerous, their environmental impact is a significant consideration. We are committed to advancing sustainable development through dedicated practices:

- Enhancing Recyclability: Plastics such as PET and HDPE are highly recyclable. We are dedicated to improving recycling efficiency, thereby reducing waste and conserving valuable resources.

- Optimizing Production: We continuously explore more energy-efficient and environmentally conscious production processes to lessen dependence on non-renewable resources.

- Responsible Waste Management: For plastics that are challenging to recycle, we actively seek appropriate disposal methods designed to minimize their environmental persistence and protect ecosystems.

Our Commitment to Sustainable Practices:

- Promoting Recycling Programs: We encourage broad societal participation in rigid plastic recycling initiatives to collectively lessen the environmental burden.

- Investing in Biodegradable and Innovative Materials: We focus on and invest in the research and development of biodegradable plastics and other eco-friendly alternatives, diligently seeking greener material solutions.

- Advocating for Rational Usage: We promote the selection of reusable products and the minimization of single-use plastic consumption, aiming to contribute to environmental protection at the source.

Conclusion: Smart Choices, Shaping the Future Together

From the resilience of HDPE to the formidable strength of PC, each type of rigid plastic fulfills a critical role in modern industry and daily life, distinguished by its unique set of properties. A thorough understanding of their characteristics and applications not only empowers us to make informed material choices tailored to specific needs but also underscores the importance of addressing environmental impacts and championing sustainable development. Through innovative thinking and a responsible approach, we can collectively shape a more sustainable and prosperous future.