Transform Plastic Film Waste into High-Value Resources with Our Advanced Washing Line

Our complete Plastic Film Washing Line is engineered for recycling operators seeking to process heavily contaminated materials. We solve the challenge of inefficient cleaning and high moisture content, delivering pure, dry plastic flakes ready for pelletizing and profitable reuse.

- Removes oils, adhesives, and stubborn contaminants

- Achieves flakes below 3% residual moisture

- Handles LDPE, PP, BOPP films, woven bags, and more

Key Benefits

Quick highlights that power modern, reliable recycling operations.

Lower Moisture, Higher Yield

Consistently reach sub-3% moisture for efficient pelletizing and stable throughput.

Superior Decontamination

Removes oils, labels, glue, and fines for cleaner flakes and fewer rejects.

Broad Material Compatibility

Handles LDPE/LLDPE films, BOPP, non-woven PP, artificial grass, and more.

Efficient Utilities

Optimized washing loop cuts water and energy usage to lower operating costs.

Robust, Low-Maintenance Design

Industrial components built for uptime with simplified service and spare parts.

Scalable & Customizable

Configurable layout and capacities to match your floor plan and growth.

Recyclable Materials Showcase

Common feedstocks the washing line transforms into clean, high-value flakes.

Plastic Film

LDPE/LLDPE post-consumer or agricultural films.

Non-Woven Bags

PP non-woven fabric scraps and bags.

Artificial Grass

Recycling of synthetic turf and landscaping materials.

BOPP Film

Post-industrial Biaxially Oriented Polypropylene films.

Mulch Plastic Film

Heavily contaminated agricultural mulch films.

Woven Bags

PP woven sacks and bulk bags (FIBCs).

Our Process

Six tightly integrated stages remove contamination, reduce moisture, and prepare plastics for profitable reuse.

Pre-Washing & Sorting

Large contaminants are removed, preparing materials for optimized processing in subsequent stages.

Granulation

Materials are uniformly reduced in size, enabling more effective washing and downstream handling.

Intensive Hot Washing

High-temperature washing with tailored chemical agents removes oils, adhesives, and stubborn contaminants.

Separation & Rinsing

Advanced separation removes dense contaminants and isolates high-quality plastic materials for reuse.

Mechanical Dewatering

Efficient centrifugal dewatering slashes moisture content ahead of final drying.

Thermal Drying

Carefully controlled thermal drying achieves low residual moisture for premium-grade flakes.

Key Components

Belt Conveyor Specifications

- Material: PVC

- Belt Thickness: 0.4mm

- With Belt Tensioning Device and Receiving Hopper

- Belt Width & Length: Customized based on output size

- Transporting raw materials into the system.

Single-Shaft Shredder Specifications

- Rotor Speed: 60-100 RPM

- Blade Material: High-strength alloy steel or D2 steel

- Cutting Chamber: 400mm x 500mm to 2000mm x 2000mm

- Screen Filter Size: 40mm - 100mm (customizable)

- Motor Power: 15-200 kW

- Shredding diverse waste materials.

- Pre-conditioning materials for recycling.

- Minimizing material size for easy handling.

Wet Plastic Granulator Specifications

- Rotor Speed: 400-600 RPM

- Blade Material: D2 high-carbon, high-chromium steel

- Cutting Arrangements: V-shape or double-scissor cut

- Screen Filter Size: 10mm - 100mm (customizable)

- Cutting plastic materials into uniform flakes.

- Pre-cleaning and loosening contaminants.

- Reducing dust buildup in recycling plants.

Friction Washer Specifications

- Rotor Speed: 500-600 RPM

- Water System: Top inlet, bottom outlet

- Operation: Continuous

- Cleaning Method: High-speed friction

- Scrubbing and cleaning plastic materials.

- Transporting materials between machines.

- Removing soil, sand, and other contaminants.

Floating Separation Tank Specifications

- Interior Width: 1000mm - 1800mm

- Total Length: 4 - 7 meters

- Interior Material: Type 304 Stainless Steel

- Exterior Frame: Carbon Steel

- Paddle Motors: 1.5KW × 2 (frequency control)

- "W" shaped bottom for improved efficiency.

- Dual-section design for better contamination management.

- Water-based separation for polyolefins (PP/PE).

Hot Washer Specifications

- Operation Mode: Continuous or batch (customizable)

- Heating System: Built-in electric heating

- Washing Method: Hot water bath with chemical additives

- Suitable Materials: PE films, woven fabrics, and other contaminated plastics

- Effective removal of oil, glue, and stubborn contaminants.

- Integrated heating system eliminates need for external boiler.

- Optimized use of chemical agents for enhanced cleaning.

Centrifugal Dryer Specifications

- Rotation Speed: Approx. 1,000 RPM

- Moisture Reduction: To approx. 20-30%

- Main Components: Rotor with paddles, mesh screen tunnel

- Casing: Metal container with external electric motor

- High efficiency with low energy consumption.

- Handles material with high water content.

- Suitable for PET flakes, PP/PE film, and other regrinds.

Thermal Pipe Dryer Specifications

- Model: RSJ800

- Blower Power: 5.5 kW

- Heating Power: 36 kW

- Pipe Diameter: ⌀159mm

- Pipe Material: Type 304 Stainless Steel

- Continuous drying process.

- Integrated cyclone separator for fines removal.

- Hot air dehydration system.

- Scalable design (multiple units can be used in series).

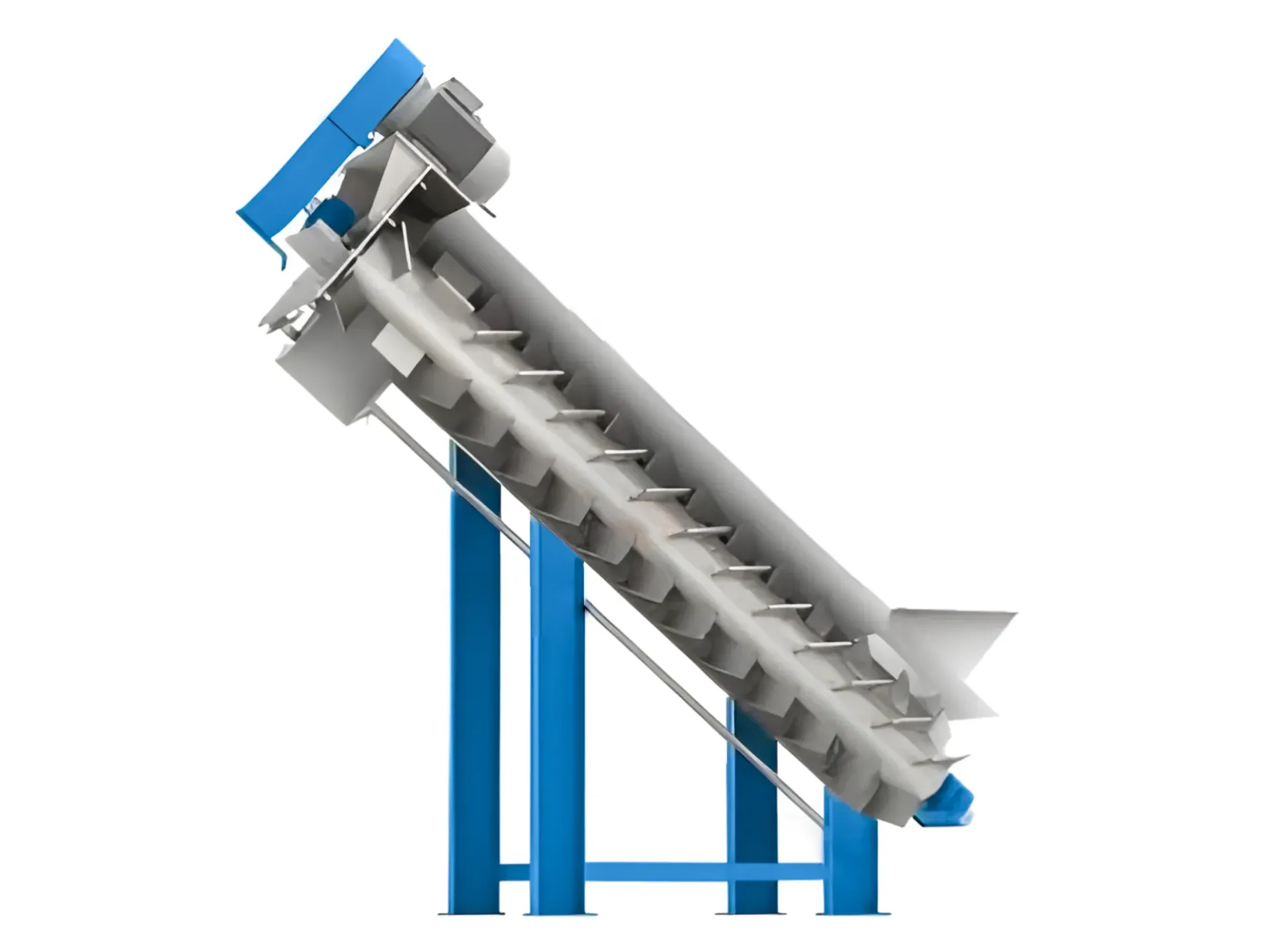

Film Squeezer Specifications

- Moisture Reduction: Lowers moisture from 10-35% down to 1-5%

- Mechanism: Screw-type compression system

- Output Capacity: 300 kg/h - 1500 kg/h

- Energy Consumption: 75 kW - 162 kW

- Efficiently reduces moisture for pelletizing.

- Compresses film flakes into dense agglomerates.

- Enhances overall recycling efficiency.

What Customers Say

Real feedback from operators who upgraded their recycling lines with us.

The washing line dramatically improved our output quality while cutting moisture levels below 3%—exactly what we needed for stable pelletizing.

Installation and training were smooth. Contamination removal is far better than our previous setup, and maintenance has been minimal.

Versatile system that handles different film grades reliably. Our downstream efficiency increased noticeably.

Frequently Asked Questions

Answers to common questions to help you evaluate the best-fit solution.

What materials can this line process?

It supports LDPE/LLDPE films, PP woven bags, BOPP films, artificial grass, and similar flexible plastics. Contact us for specific feedstock tests.

What moisture level can I expect after drying?

With the full line and proper setup, residual moisture typically falls below 3%, suitable for high-quality pelletizing.

Can the system be customized to my plant layout?

Yes. We tailor conveyor lengths, tank sizes, and dryer configurations to match your capacity and floor plan.

How is installation and training handled?

We provide on-site guidance or remote support, plus operator training to ensure a fast, confident start-up.

What is the typical lead time?

Lead times vary by configuration. Share your requirements and we’ll provide a clear production and delivery schedule.

Request Your Custom Proposal

Tell us about your materials, capacity goals, and space constraints. We’ll tailor a washing line that fits your operation.